Chasing down an elusive charging system gremlin

Intermittent problems are the worst! They always seem to happen at the worst possible time, like when you’re in the middle of nowhere away from home base. They never seem to happen when you want them to happen, like when you’re trying to show them to your A&P so he can troubleshoot and fix them.

Case in point: Nearly 30 years ago, not long after I bought my Cessna 310. I was in the middle of a 4,000-mile cross-country that took me from California to Illinois, Kansas, Oklahoma, and back home to California. I was not an A&P at the time, simply a maintenance-involved airplane owner. (The A&P would come a decade later.)

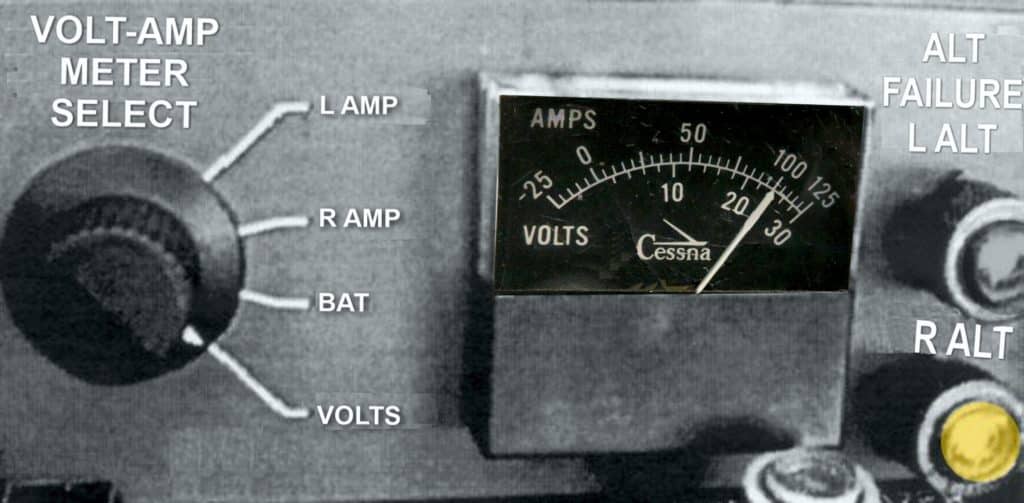

The first sign of trouble occurred as I was starting engines at Champaign, Illinois headed for Wichita. With both engines running, I noted that the amber warning light marked “ALT FAILURE: R ALT” did not go out the way it should have. I didn’t know whether this was a genuine alternator failure or just a malfunctioning idiot light, but figured I’d better try to find out.

I shut off the known good alternator (the left one) to see what would happen. What I observed was (1) the righthand alternator output current read zero amps, (2) the battery ammeter showed a discharge, (3) the bus voltage dropped from 28 to 24 volts, and (4) the red “LOW VOLT” light illuminated. That pretty much settled it: The right alternator was kaput. (This diagnostic routine took all of about 10 seconds.)

Go or no-go? The conservative decision would have been to shut down the engines and try to find a mechanic. That also would have been the FAA-approved thing to do. Both alternators are required equipment so per FAR 91.213(d) my Cessna 310 with one non-functioning alternator was legally unairworthy.

On the other hand, doing this would probably mean that I’d have to cancel my appointments in Wichita an Independence, Kansas, and Tulsa, Oklahoma. Wichita also seemed like a much better place to deal with this issue, since it’s home to one of the best twin Cessna shops in the country (Yingling Aircraft) as well as the world’s best supply of Cessna parts. The weather was severe VFR, so I didn’t consider a flight with one alternator inop to be even slightly risky.

Transient anomaly?

As all this was going through my mind, something truly unexpected occurred: The amber “ALT FAILURE: R ALT” light went out! I quickly repeated my earlier confirmation procedure and there was no doubt about it—the right alternator had spontaneously risen from the dead and was working just fine now. Yee haw!

My agonizing go/no-go decision was now a no-brainer. I launched for Wichita. As fate would have it, the right alternator performed flawlessly during the entire three-hour flight to Wichita. Two days later, it worked just fine during the short hop to Independence, Kansas. Ditto on the leg from there to Tulsa. The next day, it never once hiccupped during the eight-hour flight to California (which included a fuel stop at Albuquerque).

I’ve developed a term for a problem like this that appears briefly and then goes away without explanation: “transient anomaly.” I’ve run into plenty of them over my five decades as an aircraft owner. If you bring such a problem to an A&P while it’s still in the transient phase, chances are the mechanic won’t be able to duplicate it and so won’t be able to troubleshoot it systematically and will have no choice but to resort to a “shotgun” approach—replacing parts and hoping to get lucky.

I’ve learned that a better way to deal with most such problems is to be patient, sit tight, wait awhile, and see what happens. If you do this, generally one of two things will happen: either the problem will get worse, or it will go away. If it gets worse, then it’ll be reproducible and a whole lot easier for you or your mechanic to troubleshoot. If it goes away, it’s probably not worth worrying about…unless and until it comes back.

IMPORTANT: This “see what happens” philosophy is appropriate only when dealing with non-life-threatening problems. If you see your oil pressure fluctuate for 30 seconds and then everything returns to normal, I would definitely NOT recommend taking the “sit tight and wait awhile” approach.

It’s BAAAAACK!

After returning to California, the plane sat in the hangar for three weeks. Then I needed to fly to Tucson, Arizona to do some teaching at an aviation event there. When I started the engines, the right alternator did not come on-line—seemingly a replay of the scenario I’d faced in Champaign, Illinois a month earlier. How lovely!

I let the engines idle for a minute, hoping that the problem “cure itself” as it had before. Nope. I waited another minute. No dice. Darn!

Once again, I agonized over my go/no-go decision. There’s an excellent shop at Tucson where the problem could be worked on while I gave my seminars. No chance anyone had a replacement Prestolite 100-amp alternator on the field at my home airport, so it would take me at least a day to get one overnighted and another day to get it installed. Besides, I wasn’t even sure the alternator itself was at fault. The symptoms could just as easily be caused by a bad regulator, a bad field switch, fuse, fuse holder, wire, loose connection, or cold solder joint. Clearly some serious troubleshooting was the first order of business.

The weather enroute to Tucson was severe clear. Making the flight on one alternator would be perfectly safe, I told myself, albeit not exactly legal. I started taxiing out to the runup area, still not sure what I’d do when I got there.

About halfway to the runup area, the right alternator spontaneously came online. Once again, my decision was made for me. I flew to Tucson. The alternator worked fine. “Just as soon as I get home,” I promised myself, “I simply MUST troubleshoot this problem and get it fixed.” I had a long trip planned for the following month that would take me all the way to Key West and then over Cuba to Grand Cayman. Can’t undertake a trip like this with a flaky charging system!

As if to hold me to that promise, the right alternator failed again during the return flight from Tucson and never came back. I was actually happy about that, knowing it would make my troubleshooting vastly easier—not to mention compulsory.

Troubleshooting

The next morning, I drove to my hangar with my trusty Fluke 77 multimeter, a couple of alligator clip leads and my parts and service manuals, determined to get to the bottom of this once and for all. I had no idea what portion of the charging system was at fault, but since the regulator was the easiest component to get at—mounted beneath the copilot’s seat—I figured that was as good a place to start as any.

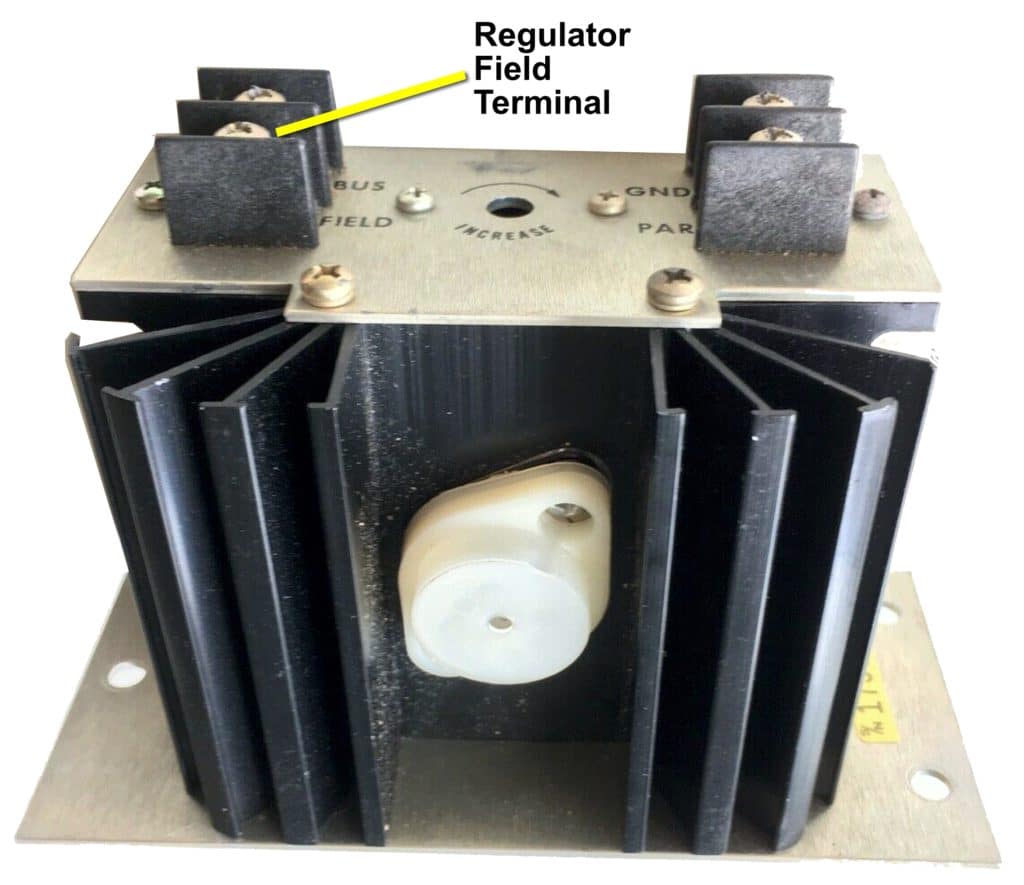

I turned on the battery and alternator switches, then measured the voltage at the regulator field terminal. It was 24 volts, just as it should be. I disconnected the field wire from the regulator and inserted my meter to measure the field current going to the alternator. It was about 1.75 amps, which seemed about right. This convinced me that the regulator was fine and the fault was more likely in the alternator itself, or maybe a problem with the field wire running from the regulator to the alternator.

With the meter still connected, I climbed out of the cockpit grabbed a blade of the right propeller and watched the meter as I rotated the prop. The field current started jumping between zero to 1.75 amps in highly erratic fashion. Aha! Clearly, there was some internal alternator problem affecting the continuity of the field.

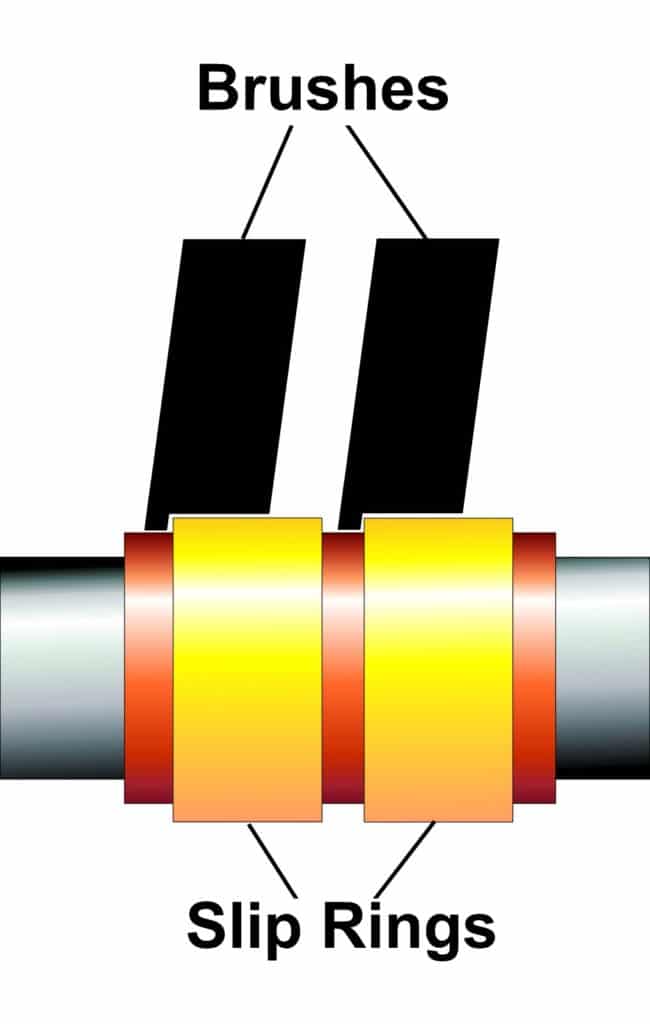

As I continued rotating the prop, I heard a funny noise coming from the front-mounted alternator, and something caught my eye. It was electrical arcing visible through the cooling slots in the alternator end cap. Every time the field current jumped from 1.75 amps to zero, I could see and hear a spark inside the alternator, in the vicinity of the brushes and slip rings.

That settled it. The fault was inside the alternator, and the alternator was going to have to come off for repair or replacement. Darn!

Fixing It

Removing the alternator sounded like something I might like to tackle myself. Since I wasn’t an A&P at the time and this wasn’t exactly preventive maintenance task that a pilot-rated aircraft owners was supposed to do on own recognizance, I asked my colleague Tom Carr A&P/IA if he’d be willing to supervise and sign off my work. Tom said okay. I asked if he wanted to watch. “Not really,” Tom said. “Just holler if you need help.” About 30 minutes later, I had the alternator off the airplane and in my hands. (Getting it off was easy, but I could tell that reinstalling it was going to be a lot trickier.)

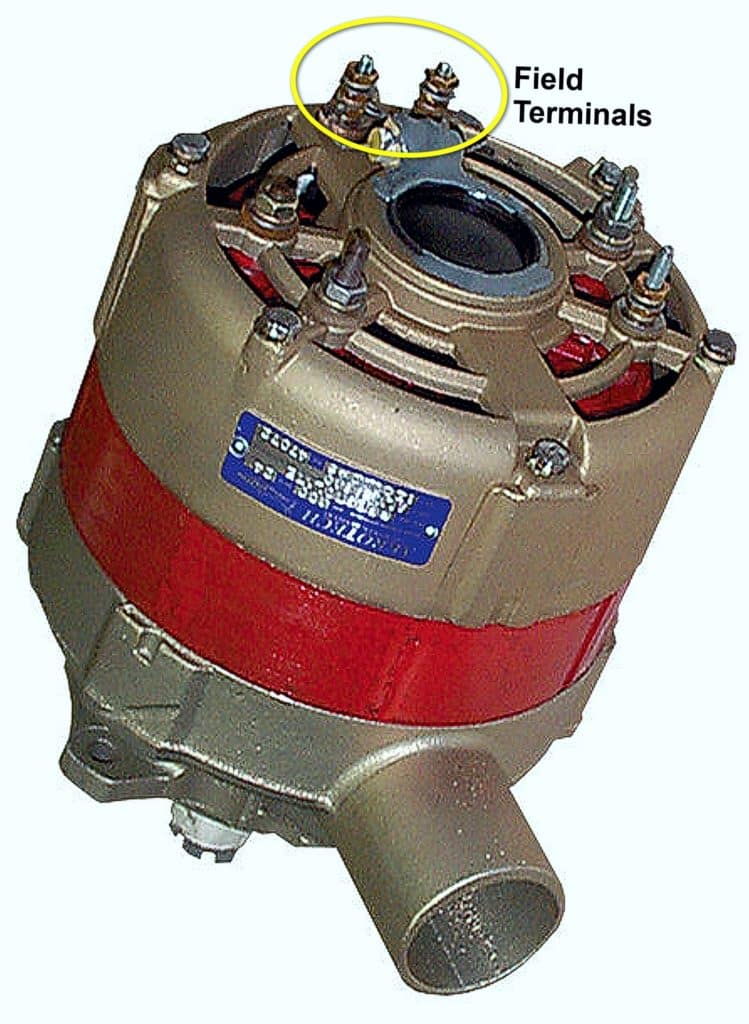

I put my ohmmeter across the alternator field terminals to verify that the resistance jumped all over the place as I rotated the alternator shaft by hand. Clearly a problem with the field, probably bad brushes or slip rings. My maintenance records indicated that this alternator had been in service for only about 400 hours—pretty youthful for something that theoretically should make it to engine TBO.

At this point, most mechanics or shops would simply order a replacement alternator at a cost of about $2,200 overhauled/exchange. I considered the possibility of opening up the alternator try to find out what was wrong with it, but Tom Carr convinced me that we didn’t have the necessary tools or parts to put it back together or test it properly.

I started making phone calls and finally located a specialty shop in Southern California that was willing to do an “IRAN” on my alternator. (“IRAN” stands for “Inspect and Repair As Necessary” and means “don’t do a full overhaul, just fix what’s broken.”) I boxed up the alternator and took it to UPS. The shop received it the next day and had it repaired, tested, and on its way back to me within 24 hours. Naturally, I was curious what the shop found wrong with my alternator, so I phoned them to find out.

Turns out the brush holder was bent so the brushes weren’t properly aligned with the slip rings—probably the result of a sloppy overhaul. The misaligned brushes gradually developed a “lip” where they hung off the edge of the slip rings. In time, the lip got big enough to touch the rotor and prevent the brushes from making proper contact. The solution was simply to bend the brush holder back to its proper shape and install new brushes. The shop also cleaned the slip rings, inspected the rotor, stator and diodes, put the alternator back together and bench-tested it. They even threw in a new mounting

I showed Tom Carr the repaired alternator and the accompanying maintenance release paperwork, and told him I was ready to reinstall the alternator on the right engine. “Holler if you need help,” said Tom, “and I’ll need to inspect the installation before you cowl up the engine.” It took me nearly two hours, a bunch of cussing, and a couple of trick wrenches borrowed from Tom’s toolbox to install the alternator. Tom inspected my work and gave it a thumbs-up. I re-cowled the engine, pulled the aircraft out of the hangar, fired up the engines, and gave the charging system an extra thorough “smoke test.” I typed up a logbook entry on a self-adhesive sticker and brought it to Tom for his approval signature. Finally, I took the airplane up on a 30-minute test flight. Everything worked exactly as advertised.

Be Patient

As I think about this episode three decades later, it occurs to me that I managed to do a lot of things right. Instead of “shotgunning” this non-life-threatening issue at the highly transient stage, I waited patiently until it got worse so it could be reproduced. Then instead of replacing components and hoping to get lucky, I dusted off my multimeter and troubleshot systematically until I determined precisely where the problem was. Finally, instead of spending $2,200 on an overhaul/exchange alternator, I got mine IRAN’d for a nickel on the dollar.

I certainly don’t expect every airplane owner to be as maintenance-involved as I was when this happened 30 years ago, but I do think there are lessons here that can benefit every owner. Perhaps the most important is to try hard never to ask a technician to fix an intermittent problem he is unlikely to be able to reproduce. If you do, the technician will be forced to “shotgun” the problem and you probably won’t be happy with the outcome—or the invoice. Patience is a virtue.

You bought a plane to fly it, not stress over maintenance.

At Savvy Aviation, we believe you shouldn’t have to navigate the complexities of aircraft maintenance alone. And you definitely shouldn’t be surprised when your shop’s invoice arrives.

Savvy Aviation isn’t a maintenance shop – we empower you with the knowledge and expert consultation you need to be in control of your own maintenance events – so your shop takes directives (not gives them). Whatever your maintenance needs, Savvy has a perfect plan for you: