How reliable and valid is the almighty compression test?

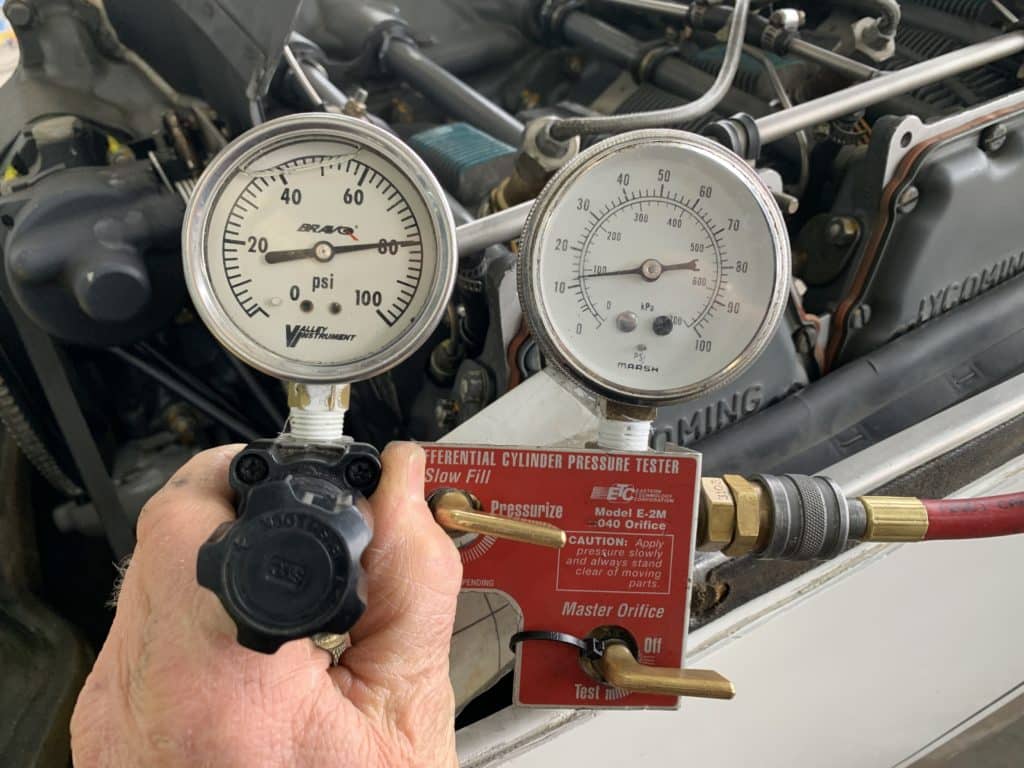

Each annual inspection begins with a moment of terror when the IA removes the top spark plugs and takes a compression reading of each cylinder. We hold our breath awaiting the verdict. If the numbers are good, we exhale and relax. If not, we anticipate the sticker shock of cylinder removal and repair or replacement—and we pray that opening Pandora’s box won’t result in an even costlier verdict requiring an engine teardown or replacement.

Sound familiar? Been there and done that? I certainly have.This agonizing compression testing ritual takes place hundreds of thousands of times each year. The requirement for performing a compression test at each annual and 100-hour inspection is written right into the FARs—specifically Part 43 Appendix D—so your IA has no choice about doing it. I’ve seen serious buyers walk away from an excellent airplane because they didn’t like the looks of the compression readings during the pre-buy.

Yet this obsession with compression readings is so very wrong on multiple levels. Why wrong? I will explain…

For one thing, the differential compression test is spectacularly unreliable. This means that you can test a cylinder multiple times and get wildly different test results. A cylinder whose compression reading is abysmal can exhibit excellent compression when re-tested after flying for 45 minutes. No sane person should trust a test like that.

For another, the differential compression test is not a valid test of cylinder condition. This means that a healthy cylinder can exhibit poor compression readings, and a sick cylinder can exhibit good compression readings. Even if the test results were highly repeatable (which they definitely aren’t), it would never make sense to base costly, risky and invasive maintenance decisions solely on those results. Owners should insist on seeing far more trustworthy evidence before approving cylinder removal.

Finally, even if the compression test is successful in identifying a sick cylinder (which it occasionally is), that still doesn’t justify cylinder removal. Many cylinder ailments can be remediated without cylinder removal using minimally invasive procedures that are less costly and risky, and therefore obviously preferable.

Absurdly unreliable

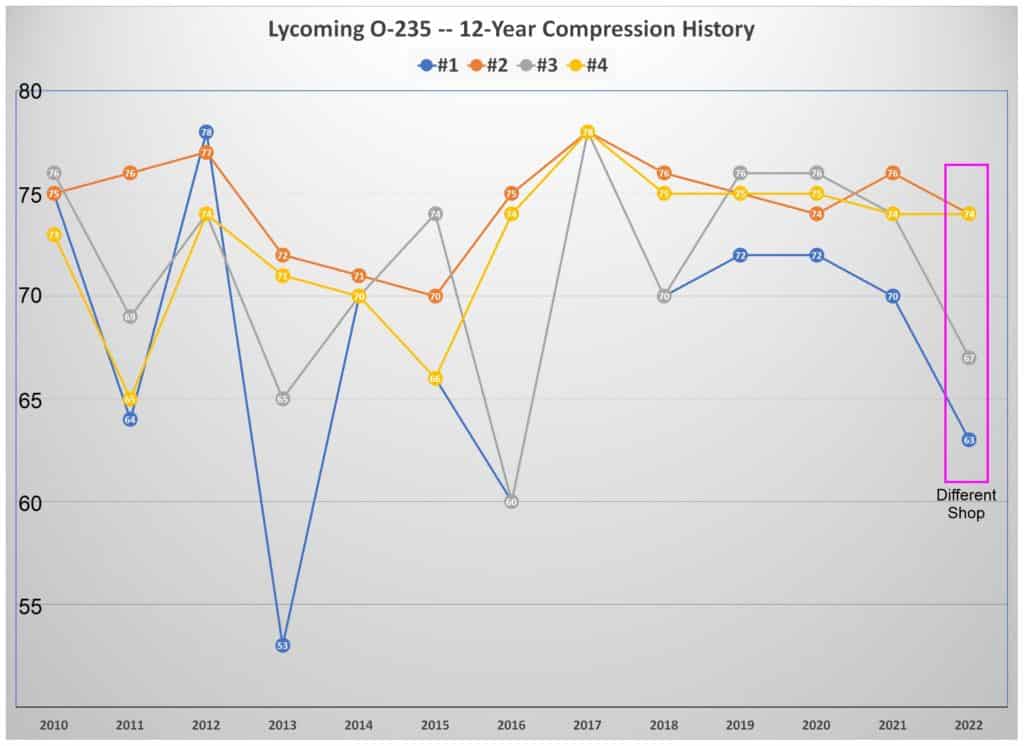

One of the most convincing demonstrations of just how unreliable the compression test is came to me recently from the longtime owner of a 1947 Piper PA-12 Cruiser. He sent me his compression readings for the 13-year period from 2010 through 2022, explaining that all but the last of these compression tests were taken by the same shop. He told me that no cylinder work had been done during this period—not all that unusual for small four-cylinder Lycomings. Here are the numbers:

A graph of these readings makes their wild gyrations a bit more obvious:

These readings were all over the place! They gyrate up and down from one annual to the next. If these readings actually reflected cylinder condition, one would expect to see a gradual deterioration over time correlating with cylinder wear, but no such trend is evident. Nor do the readings for the various cylinders move up and down together as one might expect if the readings were taken by different mechanics or under different conditions (e.g., hot vs. cold) from one year to the next.

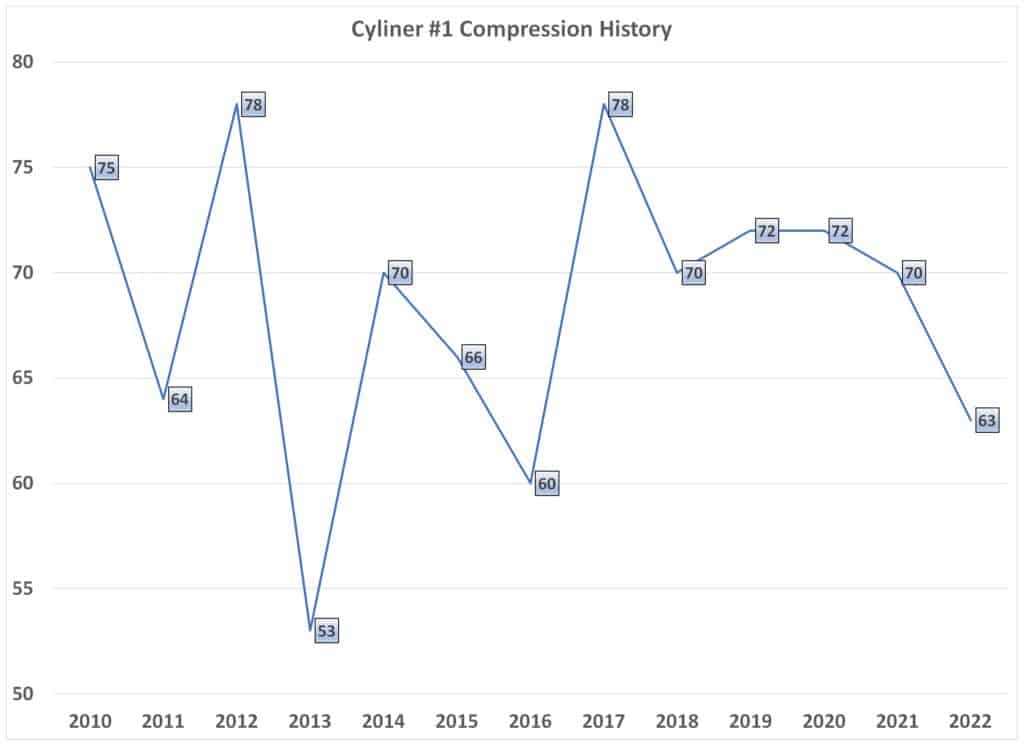

The readings for cylinder #1 are particularly crazy:

The annual compression readings for the #1 cylinder start at 75/80, then drp to 64/80, then pop back up to 78/80, then plummet to 53/80 (!), then rise to 70/80, then drop to 60/80, then shoot back up to 78/80. Do you really believe that this cylinder kept getting sick, then healed it self, then got sick again, then healed again? No, that’s not plausible.

So, what is one to make of these numbers. The only plausible explanation is that they’re mostly noise with very little signal. This agrees precisely with my own experience with compression number over my five decades as an aircraft owner.

I asked the owner how he managed to escape having the #1 jug replaced at the 2013 annual inspection when its compression was recorded at 53/80. The owner did not recall, but my theory is that his IA was smart enough to realize that the reading was clearly bogus and wisely decided not to do anything rash. Contrary to conventional wisdom, there is no requirement that a Lycoming cylinder be removed simply because it exhibits a compression reading below 60/80. Lycoming’s guidance on this subject can be found in Service Instruction No. 1191A, which states in pertinent part:

“If the pressure reading is below 60 psi or if the wear rate increases rapidly, as indicated by appreciable decrease in cylinder pressure, removal and overhaul of the cylinders should be considered.” [Emphasis mine.]

This less-than-proscriptive language give an IA considerable latitude to decide whether or not to yank a low-compression jug. And that’s definitely a good thing, because as you can see these compression readings are mostly garbage.

To understand why compression test results provide so little insight into actual cylinder health, we need to examine the causes of poor compression results. Virtually all low compression readings are caused by air leakage past the compression rings and/or air leakage past the exhaust valve. Let’s take a closer look at each of these two phenomena.

Leakage Past the Rings

Air leakage past the rings is largely an artifact of the compression test rather than a real problem with the cylinder. When the engine is running at normal operating temperatures, the piston has a very snug fit inside the cylinder walls and so very little exhaust gas is able to get past the rings.

By necessity, however, the compression test is performed with the cylinder and piston at a much lower temperature. Since the aluminum piston contracts twice as much as the steel cylinder barrel as both cool down from operating temperature, the piston has a very sloppy fit within the cylinder barrel when the compression test is performed. The cooler the cylinder and piston, the sloppier the fit. This sloppy fit would allow lots of air to escape from the combustion chamber past the piston into the crankcase if it weren’t for the piston rings—primarily the top compression ring—blocking the escape route.

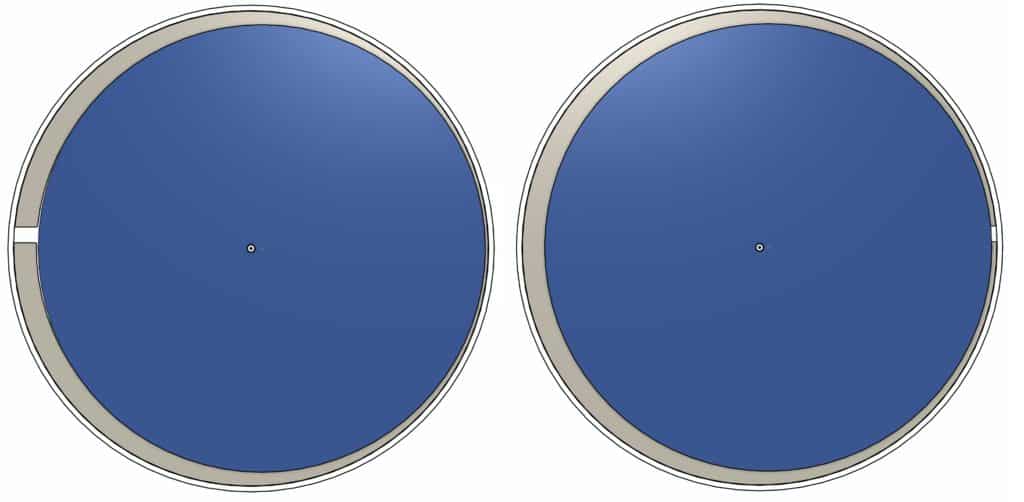

The compression rings do a pretty decent job of sealing the combustion chamber except for one thing: The rings are not continuous. They have a gap through which air can escape. This gap isn’t a big issue when the engine is actually running because the piston has such a snug fit inside the cylinder barrel. But it can cause a lot of air leakage during the compression test when the parts are relatively cool and the fits are very sloppy.

To complicate things further, the compression rings migrate during engine operation, so it’s unpredictable exactly where the ring gaps will be when the compression test is performed. This introduces a large amount of randomness in the compression readings. This graphic illustrates the problem:

When the mechanic rotates the propeller to bring the piston up to top-dead-center (TDC), the piston is cocked off-center in the barrel by the side load of the connecting rod. Depending on exactly where the ring gap is located, it can allow lots of air leakage or very little. This is why Continental recommends bringing the piston to TDC by rotating the prop in the opposite direction to see if leakage past the rings is reduced, and to record whichever compression number is better. (Very few mechanics actually do this.)

Incidentally, there is no correlation whatsoever between low compression due to leakage past the rings and engine power. To demonstrate this, Continental ran a new 300 hp IO-550 engine in its engineering test cell in Mobile and measured its horsepower output on a dynamometer. They then filed the compression ring gaps oversize to reduce the compression of all six cylinders to 40/80 and repeated the dyno test. There was no measurable decrease in horsepower.

Why? Because the piston fits very snugly in the cylinder barrel when the engine is at operating temperature, so the ring gaps don’t matter much. But during the compression test, they matter a lot. It’s an artifact of the test, not a problem with the cylinder.

Leakage Past the Exhaust Valve

Air leakage past the exhaust valve during the compression test can portend a serious problem with the valve—or not. A burned exhaust valve that has warped or suffered significant metal erosion on its sealing surface can cause a poor compression reading. But so can a valve that is not quite centered in the seat due to valve guide wear, or deposits of carbon or lead on the seat that prevent the valve from making good contact with the seat.

A burned valve is a serious problem. A worn guide or a dirty seat are generally not an issue, since the valve will still seal tightly during engine operation when the valve and seat are hot and there’s 800 to 1,000 psi pushing the valve closed. If the exhaust valve was actually leaking due to a worn guide or deposits on the seat, we would see this clearly as increased EGT readings on the engine monitor. We don’t see that, so we know the valve is sealing properly during actual operation.

To help eliminate these false positives, both Continental and Lycomings recommend “staking the valve” by removing the rocker cover and tapping the exhaust valve rocker with a mallet while the cylinder is pressurized to coax the valve to seal. Sometimes this has a dramatic effect on the compression reading when there’s leakage past the exhaust valve, and sometimes it doesn’t. It all depends on the reason for the leakage. (Few mechanics go to the trouble of doing this.)

The best way to determine the exact cause of air leakage past the exhaust valve during a compression test is to stick a borescope into the spark plug hole and take a good look. A burned valve is clearly identifiable by the asymmetric pattern of exhaust deposits on the valve face. Opening the valve and looking at it with the borescope will reveal the extent of any metal erosion or warping. If the problem is caught early enough that metal erosion is minimal, the valve can generally be saved by lapping it in place without the need for cylinder removal. When this is done, we also recommend replacing the rotator cap or rotocoil because failure to rotate is a common cause of valve burning.

With the exhaust valve fully opened, the borescope will clearly reveal the amount of deposit buildup on the valve seat. Such deposit buildup can affect compression test results, but almost never affects actual engine operation. Another artifact of the test.

The degree of valve guide wear can generally be assessed by watching the valve with a borescope as the prop is rotated to close the valve. The amount of visible “sidestepping” as the valve mates with the seat provides a good indication of valve guide wear. Continental cylinders cat tolerate a great deal of guide wear without affecting engine operation, while Lycoming cylinders are somewhat less tolerant of guide wear.

Unless the borescope reveals clear evidence of a burned exhaust valve, it is never appropriate to remove a cylinder due to leakage past the exhaust valve. Even if the valve is burned, it is often possible to remediate the issue without cylinder removal. Only if the valve is burned so badly that it’s not a good candidate for lapping should cylinder removal be undertaken.

Fundamentally Invalid

The differential compression test is a terrible test. It is highly unreliable and does not correlate well with cylinder health. The borescope is vastly better in this regard, particularly if used by a mechanic who knows what to look for.

If it weren’t for the fact that performing a compression test is a regulatory requirement, I would recommend doing away with it altogether. But, since the FAA requires us to do it, I can only recommend that its many flaws be taken into account and that poor compression readings should never be used to justify cylinder removal without strong supporting borescope evidence.

Continental’s Manual M-0 offers some excellent guidance in this regard. It lowers the compression test’s no-go threshold from the traditional 60/80 to a value based on a master orifice that generally results in a threshold in the low 40s. It mandates that a borescope inspection be performed whenever a compression test is performed (meaning at minimum at every annual and 100-hour inspection).

Finally, Continental says that if a cylinder exhibits a compression reading below the no-go threshold but the borescope inspection reveals no obvious cause for the low compression, the aircraft should be flown for at least 45 minutes and then the cylinder in question should be re-tested hot. In my experience, the compression number on the re-test is almost always at least 10 psi higher than it was on the original test. I recall one case involving a Cirrus SR22 where a cylinder that tested 38/80 was flown for an hour and then tested 72/80 on the re-test.

Lycoming sticks with the traditional 60/80 threshold, but offers “squishy” guidance that leaves it to the IA’s discretion whether or not to remove a cylinder whose compression falls below that threshold. Since we are forced to do compression tests, let’s be careful to put the resulting numbers in proper context and avoid pulling cylinders for the wrong reason.

You bought a plane to fly it, not stress over maintenance.

At Savvy Aviation, we believe you shouldn’t have to navigate the complexities of aircraft maintenance alone. And you definitely shouldn’t be surprised when your shop’s invoice arrives.

Savvy Aviation isn’t a maintenance shop – we empower you with the knowledge and expert consultation you need to be in control of your own maintenance events – so your shop takes directives (not gives them). Whatever your maintenance needs, Savvy has a perfect plan for you: