The analysis team sees lots of malfunctions in the data we review. No surprise – most clients request analysis when something’s not right, so we’re not seeing the thousands of flights that go off without a hitch. So you could say we’re spring-loaded for malfunctions. This month we had a surge in things that were broken – not just malfunctioning.

Surely the engine data offered signals that something was about to fail. Either in real time, or in post flight review. Yeah but it’s not that simple – and as they say in the movies, don’t call me Shirley. This month, Savvy’s Director of Analysis Joe Godfrey looks at data from a Cessna 206, a Bearhawk, a Cirrus SR22T and a Beech Bonanza 36.

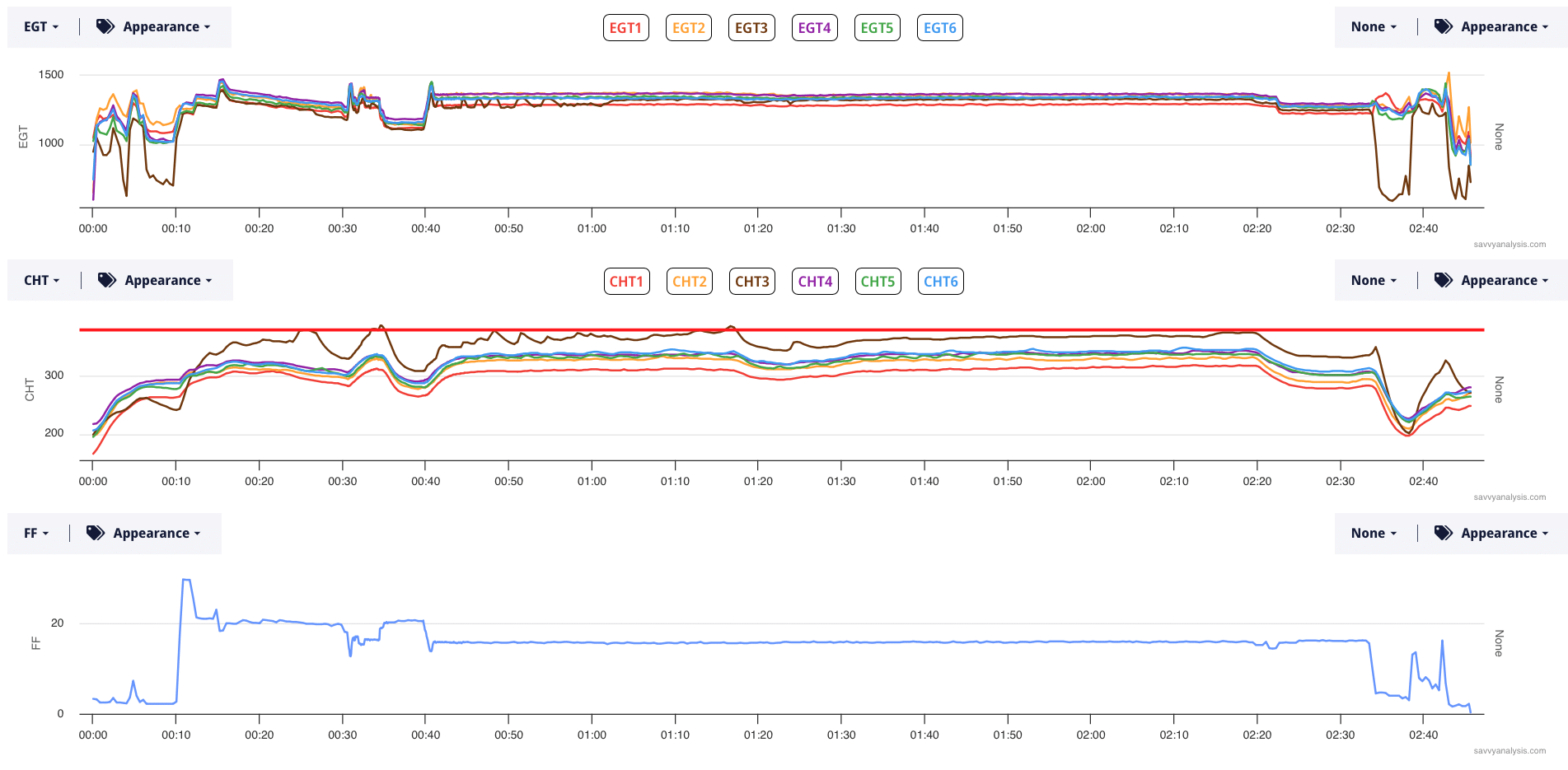

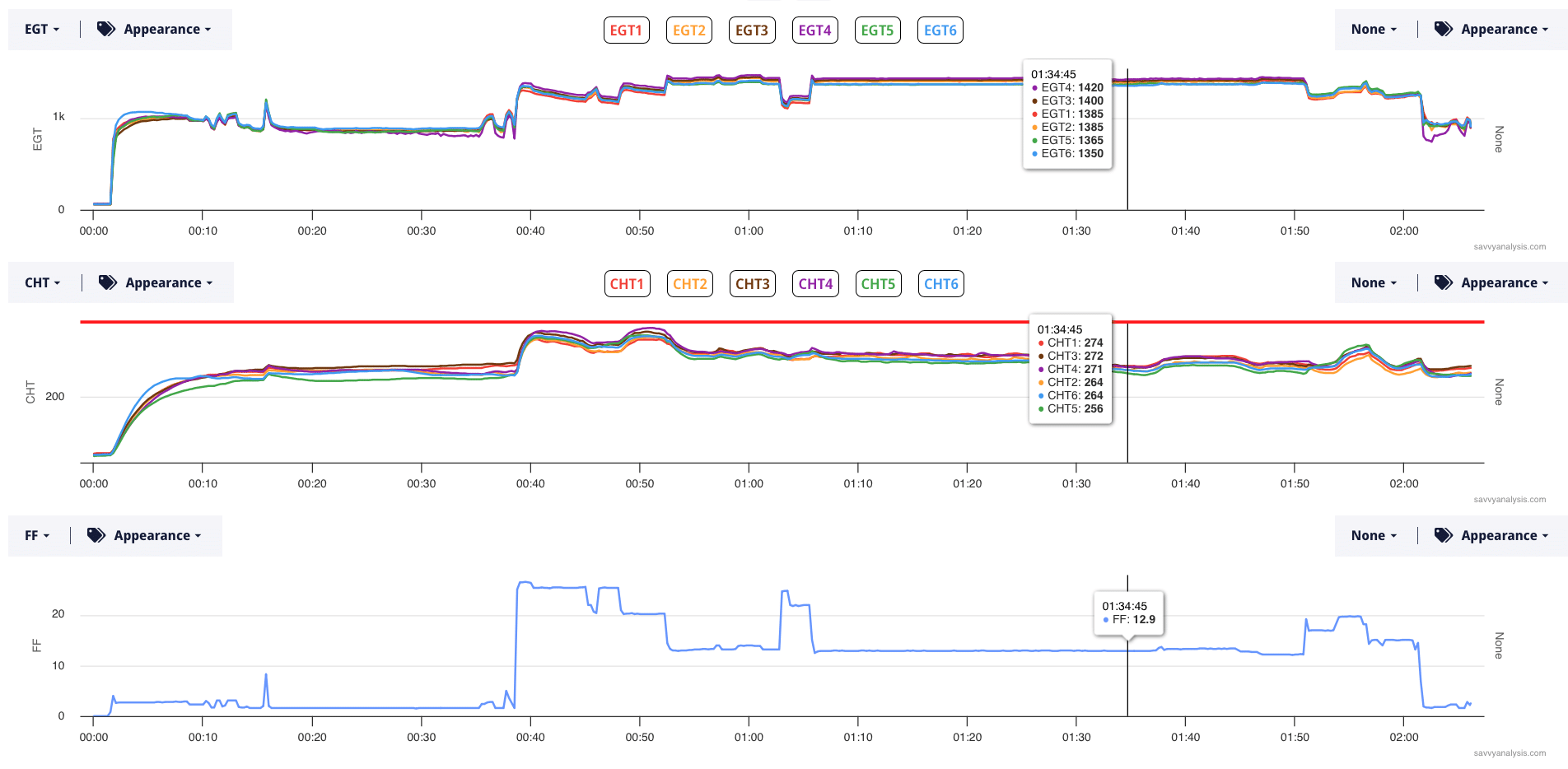

First up is data from a Cessna 206 powered by a Lycoming IO-540 with data from a JPI 900 with a 1 sec sample rate. EGTs, CHTs and FF.

There’s an early indication of trouble in EGT and CHT 3. EGT 3 is low until takeoff, then it’s up with the others. CHT 3 is also low until takeoff, then it jumps past the others and stays high – until it fails at about 2 hrs 35 mins in the timeline. Here’s another shot of the same flight with EGT and CHT 3 bolded.

There are clearly indications that something is wrong with cyl 3. The high CHT, the oscillating pattern in EGT at the end of climb at the 40 min mark, and a similar oscillation in CHT there. But by the 01:30 mark, things settle down and CHT 3, while higher than the others, is a comfortable 366º. Would you have considered or executed an emergency landing by then? Or, as this pilot did, would you press on and maybe jot down a squawk to have it looked at once you landed?

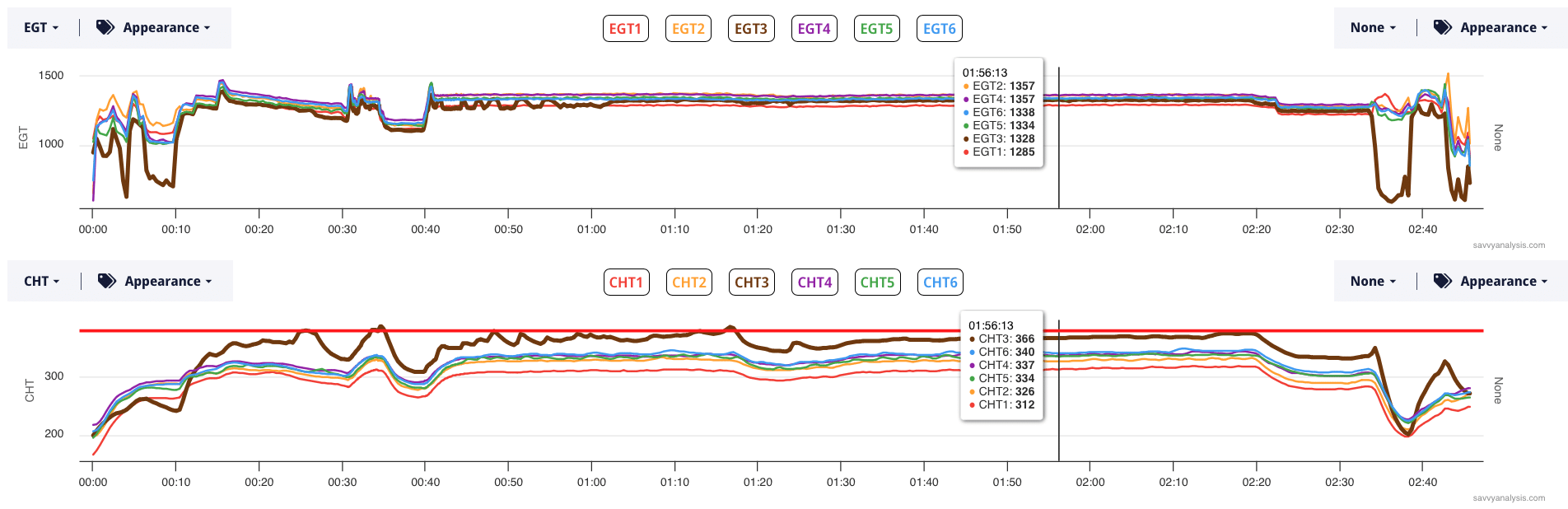

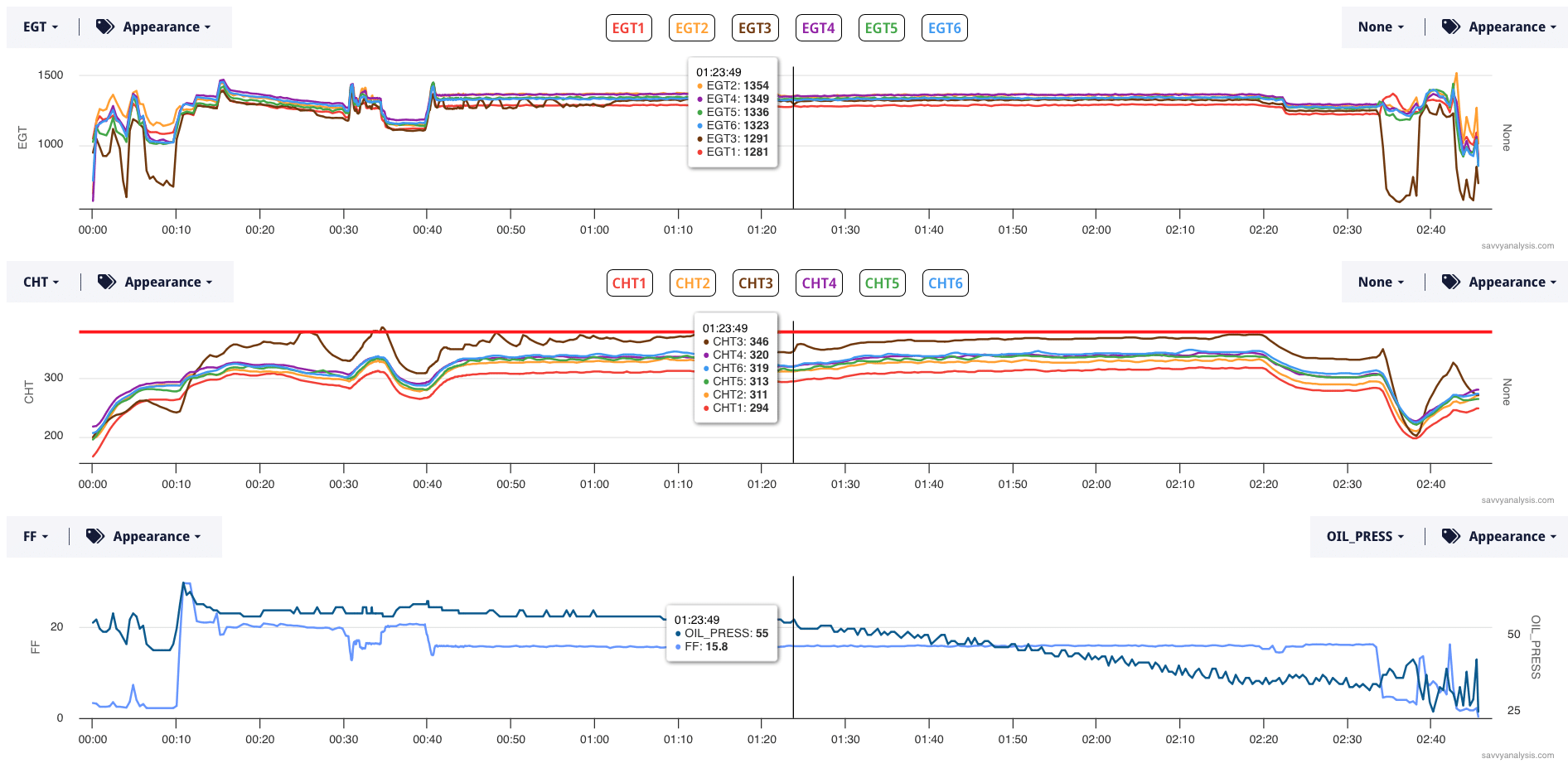

You might wonder if other recent flights offered clues or alerts about the impending failure. Negative. You might wonder if some other engine parameter offered a clue or alert. Bingo. Here’s EGT, CHT, FF and Oil pressure.

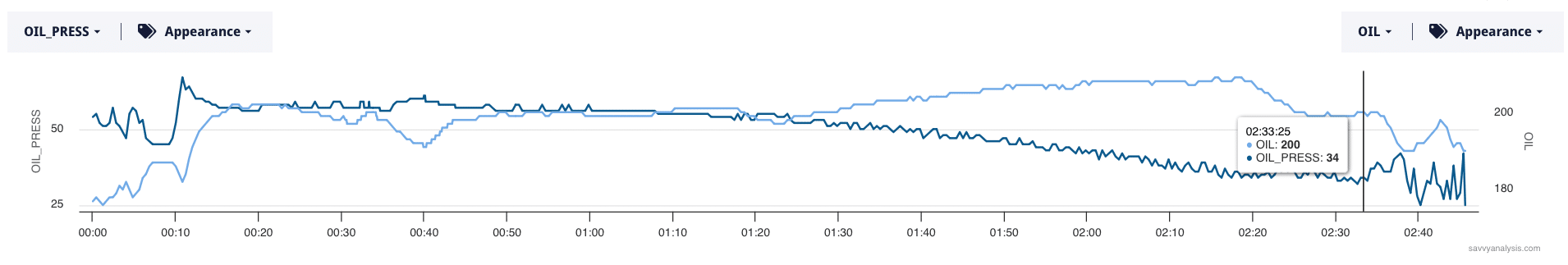

You gotta give the engine credit, It limped along with gradually decreasing oil pressure for over an hour. Pressure was 34 psi when cyl 3 suffered a catastrophic failure. You might wonder if oil temperature corroborated the drop in pressure. Bingo again.

Oil temp gets to 209º before it drops and that appears to be where the pilot reduced power, but left FF high. Two observations seemed counterintuitive – or at least out of the ordinary. Oil pressure stayed pretty even as EGT and CHT 3 jumped around during early cruise. Then starting at about 01:30 EGT and CHT 3 are pretty steady as the oil situation gradually worsens.

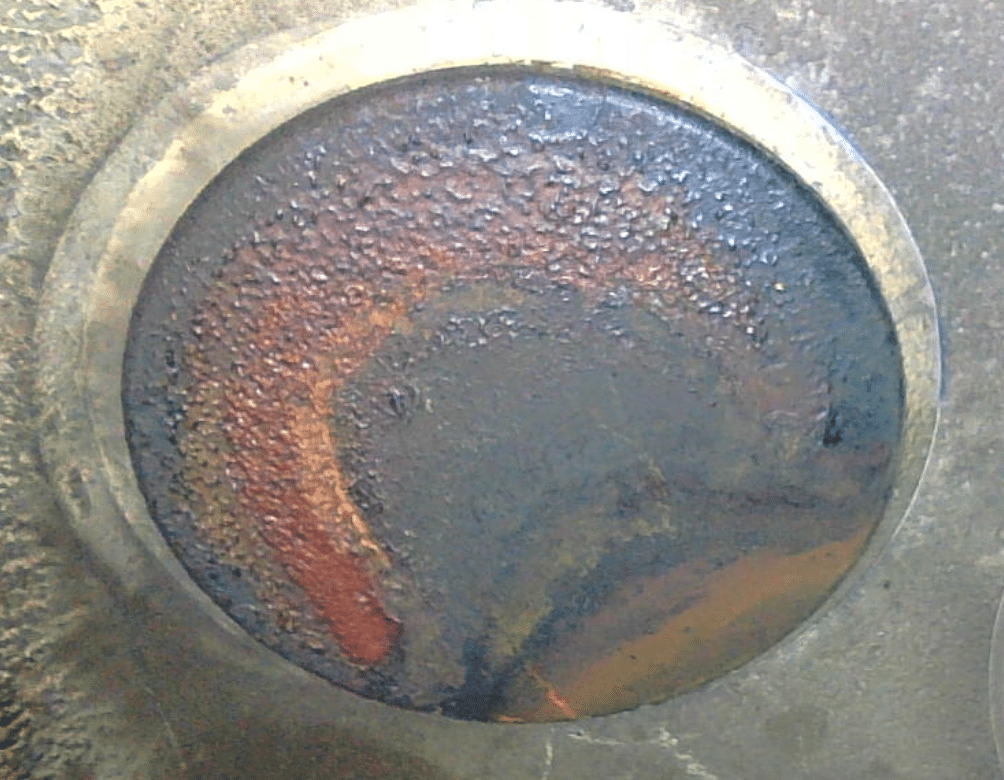

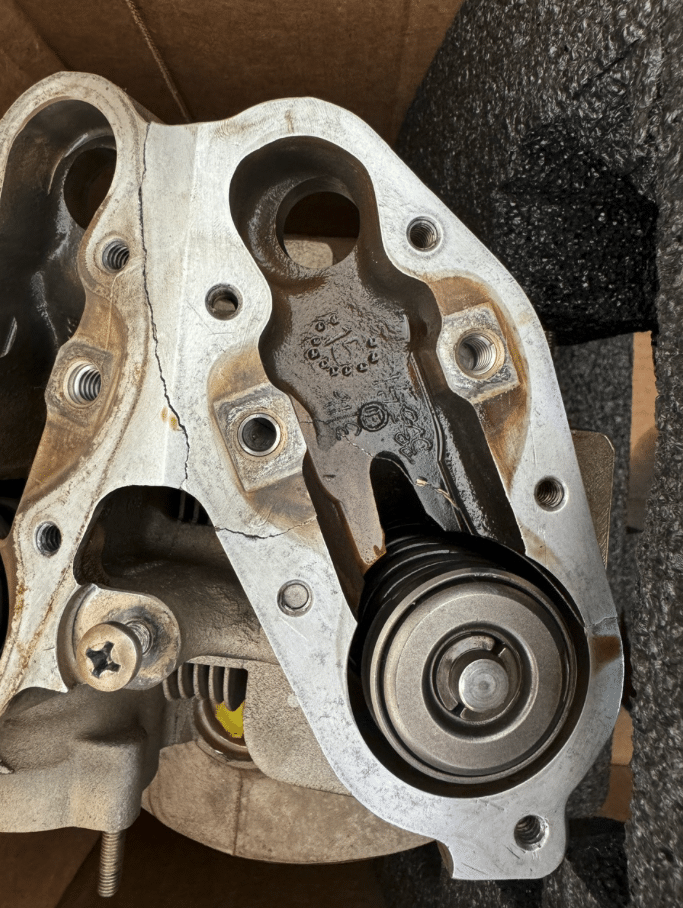

Next up is a borescope image from a Bearhawk Patrol powered by an Aero Sport O-375 with data from an MGL iEFIS.

Here’s the kicker – this is an intake valve.

As I write this we’re a little over three months into our borescope initiative and we’ve seen a couple of intake valve failures.

So as you take your pictures, we’re obviously concerned about the exhaust valves – but don’t neglect the intake valves.

I don’t have engine data to display but would expect lower EGT and CHT on this cylinder because it’s just not able to make much power with low compression..

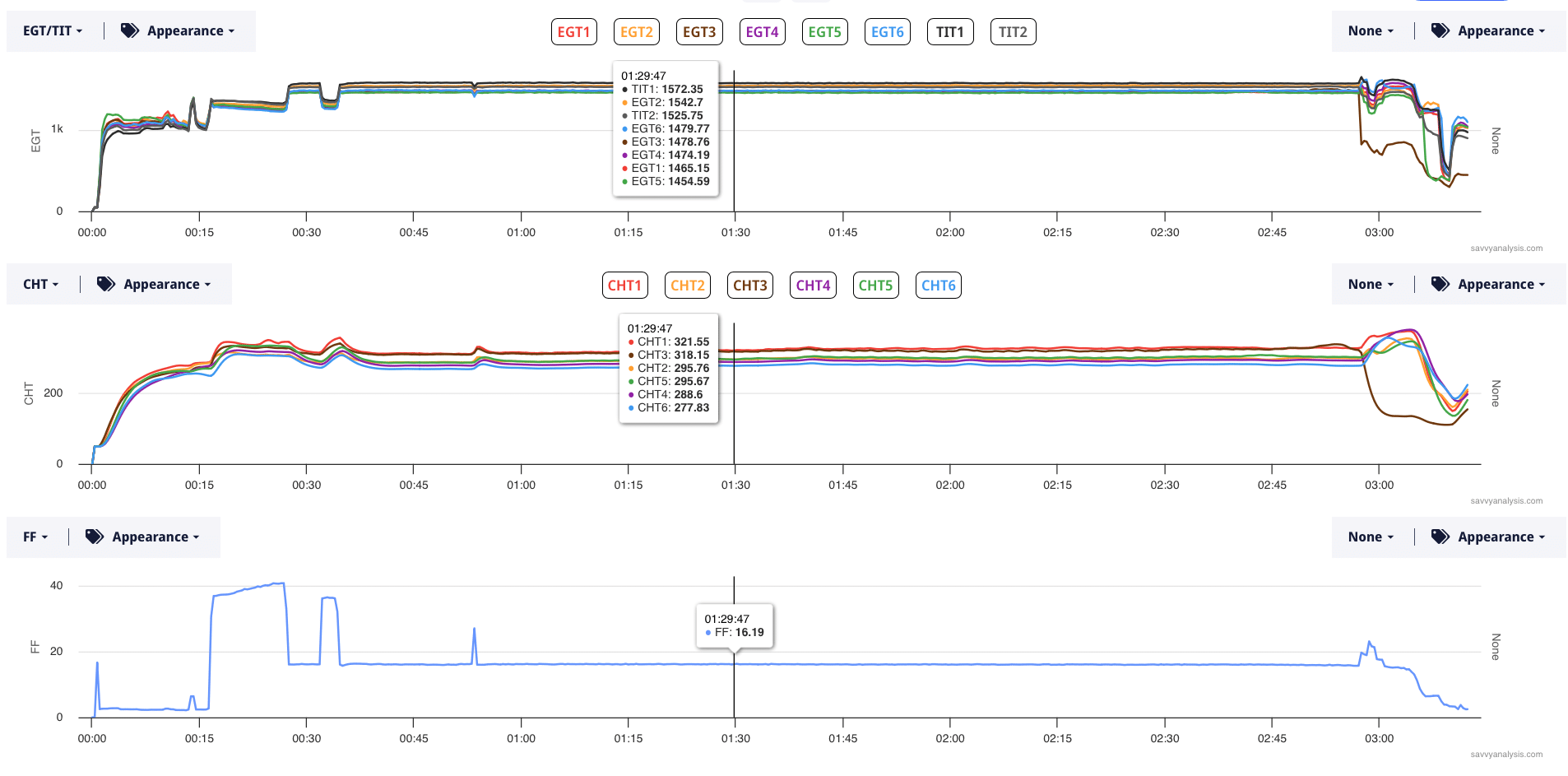

Next is data from a Beech Bonanza A36 powered by a Continental IO-550-B with data from a Garmin G3X with a 1 sec sample rate. EGTs, CHTs and FF.

Wow, that’s a 30+ minute idle waiting for a clearance. Without giving too much away let’s just say busy airport after a college football bowl game. Busy sky. EGT 4 looks a little uneven right before takeoff, but everything looks ok once the airplane is in flight. In fact, EGTs in cruise are stable and uniform with a low spread – indicating good and uniform combustion. So it was a surprise when they borescoped the engine for annual and saw asymmetrical heating on the cyl 5 exhaust valve.

The valve head isn’t broken – yet. What’s broken is the rotator cap that turns the valve in service, which is one reason we don’t see an oscillation in EGT in this or other recent flights.

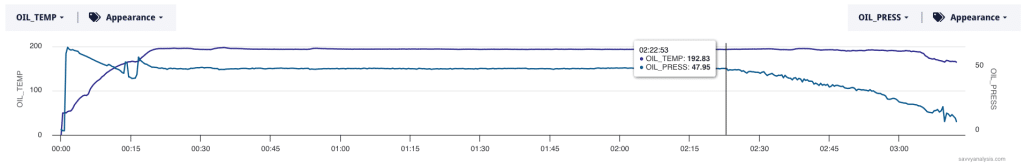

We’ll finish this month with data from a Cirrus SR22T powered by a Continental TSIO-550 with data from a Garmin Perspective with a 1 sec sample rate. EGTs (& TITs) CHTs and FF.

CHTs 1 and 3 are a little higher than the others, otherwise this data suggests a happy engine. But if you were watching oil pressure…

Earlier we saw that oil temp climbed as oil pressure dropped. Not seeing that here. Just a little wobble at 02:35. Oil pressure is about 24 when the cylinder fails.

There was a suggestion that an over-torqued rocker arm caused this. Further research showed there is an AD and a mandatory SB – 2020-16-11 and Continental MSB18-08 respectively – that apply to this engine. But for our purposes, we know that the engine data was offering a clue that something was wrong and getting worse.