When we started our engine data analysis service in 2014, I wondered if we would see seasonal patterns in the data. For instance, would we see more probe failures in the heat of the summer? Would we see more stuck valves in the colder months? Would we see more anomalies in general in the fall months after the busy flying season?

Data supports that last one, which shouldn’t surprise anyone. But in ten years of working tickets I haven’t yet been able to connect the dots on other seasonal patterns. I’ll keep looking because my spidey sense tells me there’s something to find. Meanwhile, this month’s collection covers a lot of ground in terms of issues and powerplants.

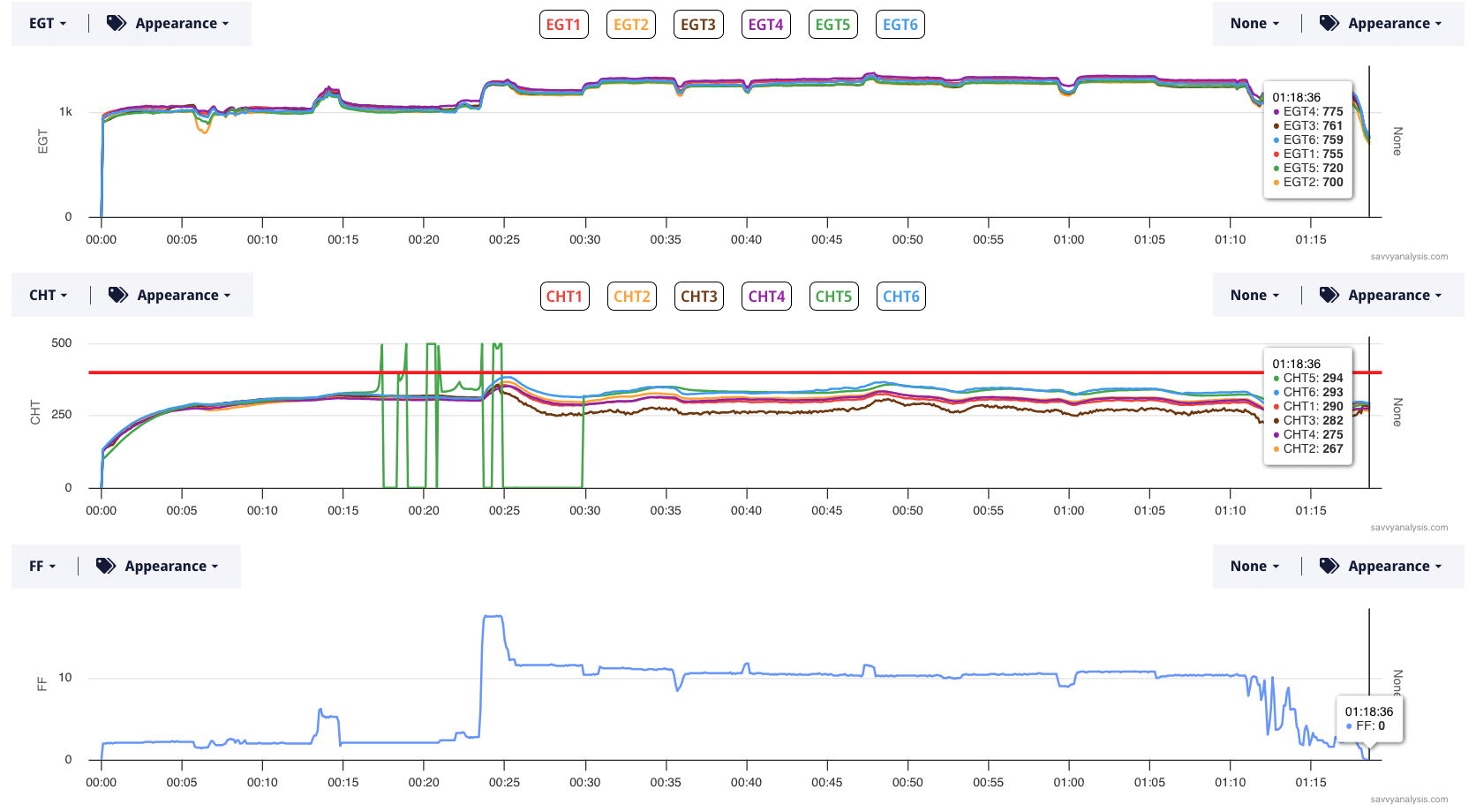

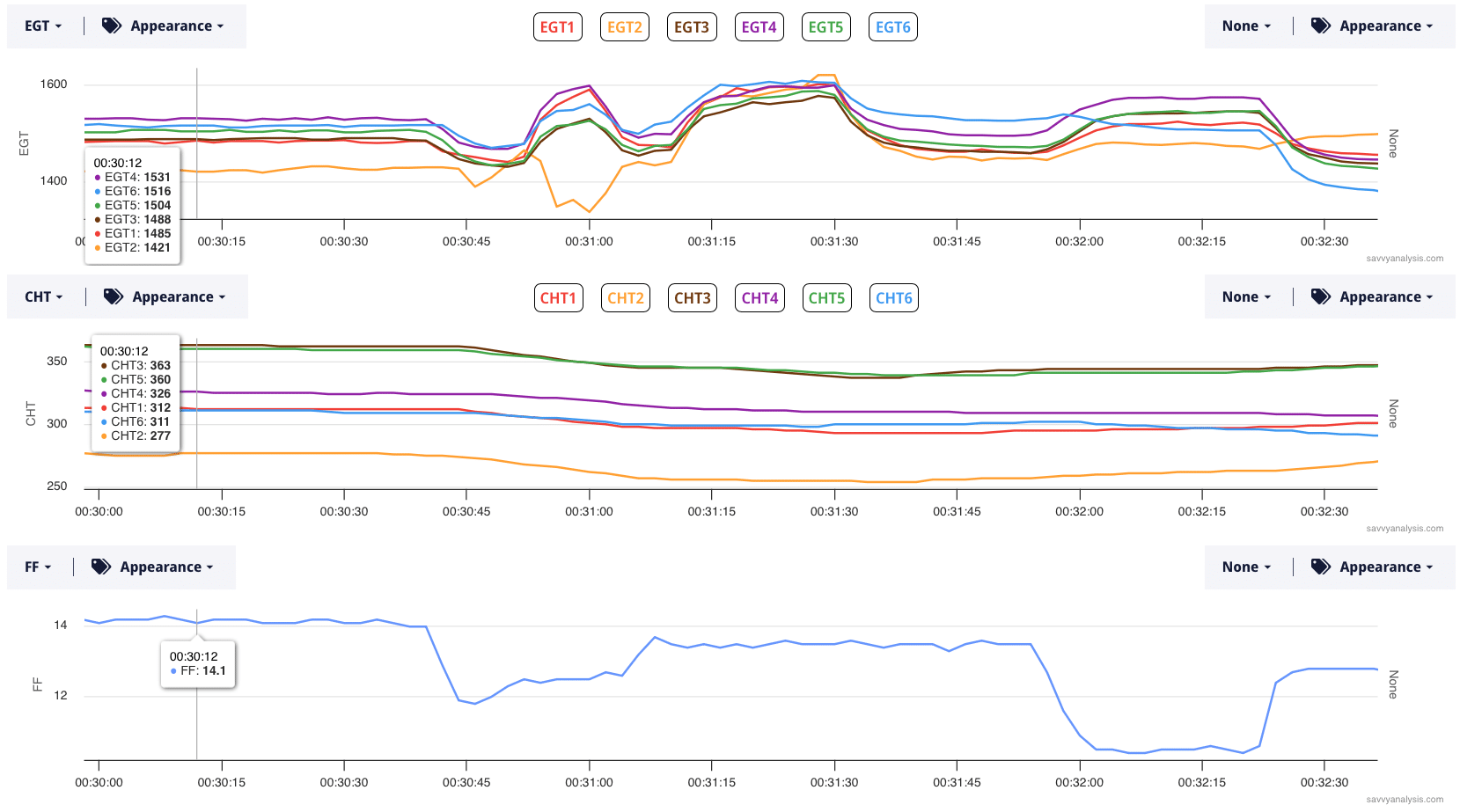

We’ll start with data from a Cirrus SR20 powered by a Continental IO-360 with data from an Avidyne Entegra with a 6 sec sample rate. EGTs on top, with CHTs and FF below. Nothing special about curser placement – just moving it out-of-the-way.

After about 15 minutes of warming up, CHT 5 starts jumping between 500º and zero. After about 15 minutes of that, it settles down and tracks CHT normally until shutdown. Meanwhile, CHT3, which was tracking normally until takeoff, is low and a little noisy for the rest of the flight. Could those two be related?

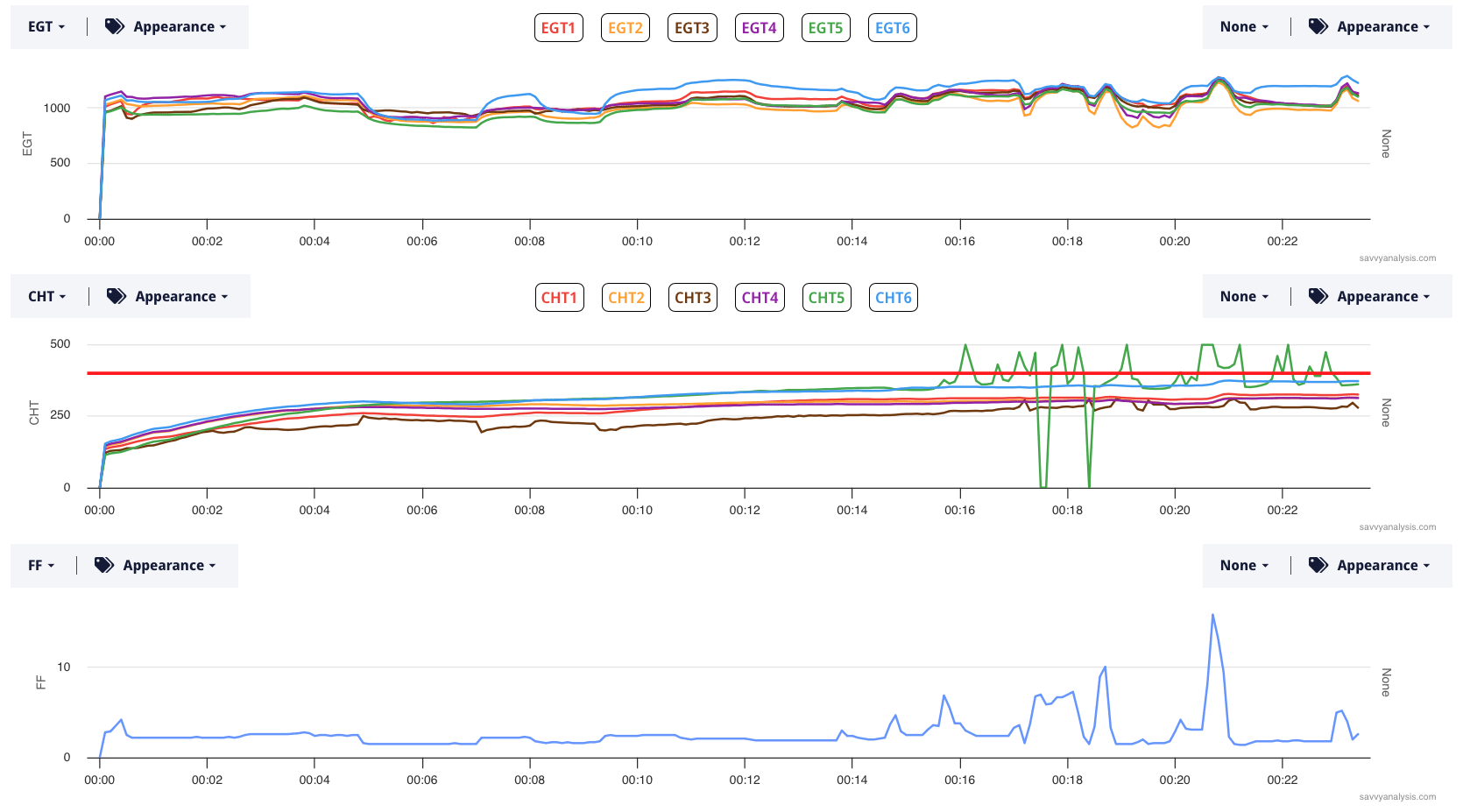

When we see what looks like a probe failure, we look at the flights before and after the submitted flight. Here’s the next engine start, which resulted in a 20 min ground run.

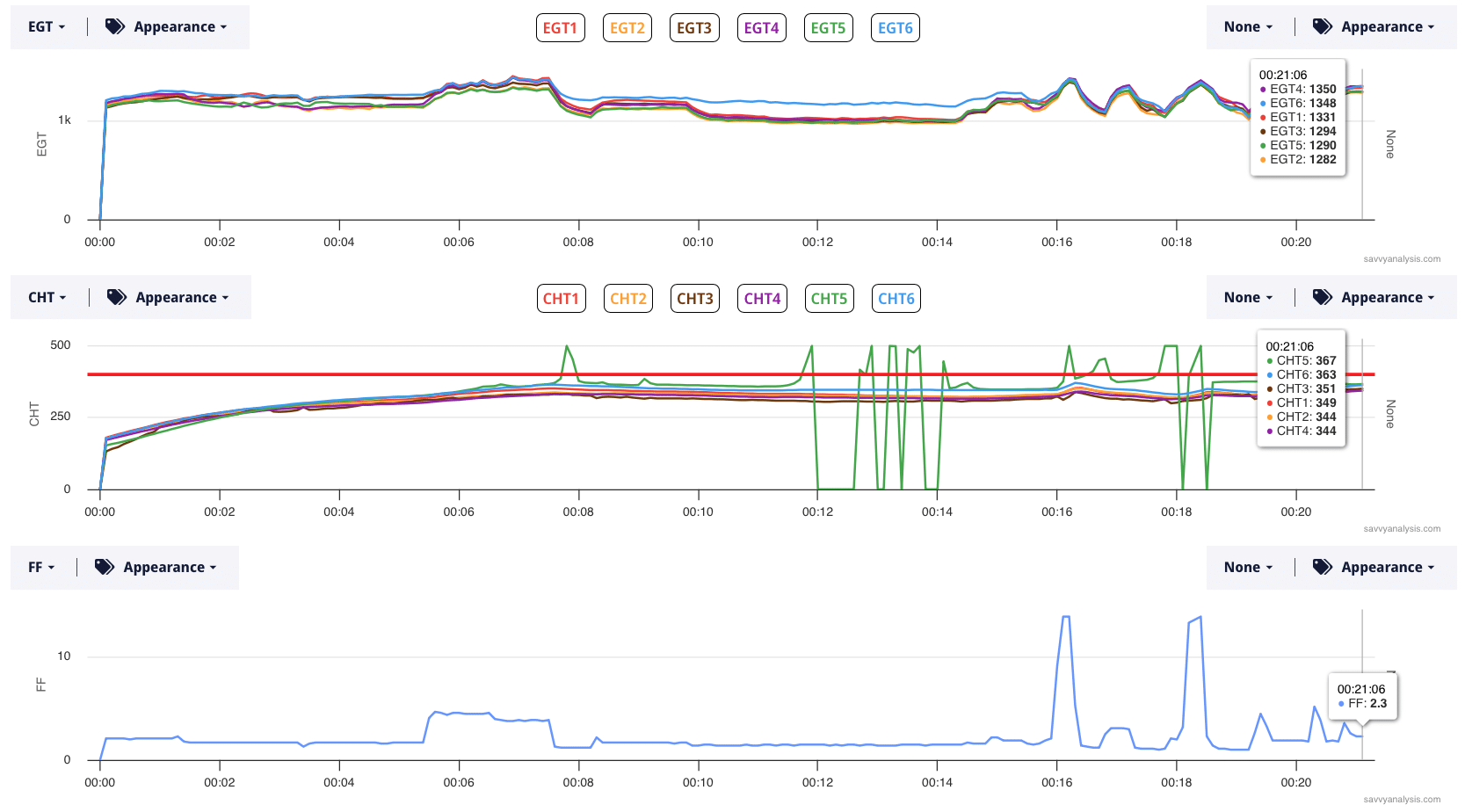

As Ross Perot used to say, I find it fascinating that the mischief again starts at the 15 min mark. That’s the kind of pattern that would drive a shop crazy trying to replicate on the ramp. And CHT 3 is not noisy as before, but it’s not tracking normally. And here’s the next ground run..

This time it acts up a little earlier. You might be wondering if the trouble starts when the probe hits a certain degree value – like 275 or 325 or 341 or whatever. No, it’s not that consistent. But that 12-15 minute timeframe is noteworthy – and much easier to spot in the data than in real time in the cockpit.

Next up is a Cessna U206 powered by a Continental IO-550 and data from a JPI 830 with a 2 sec sample rate. CHTs on top, with EGT’s and FF below. Nothing special about the cursor placement – just getting it out-of-the-way.

The overview shows EGT 2 sometimes highest and sometimes lowest, and moving with FF. CHT 2 also moves with FF. That’s a symptom of an injector clog, and the dip in EGT 2 at the 40 min mark when FF is leaned is another tick in the clogged injector column.

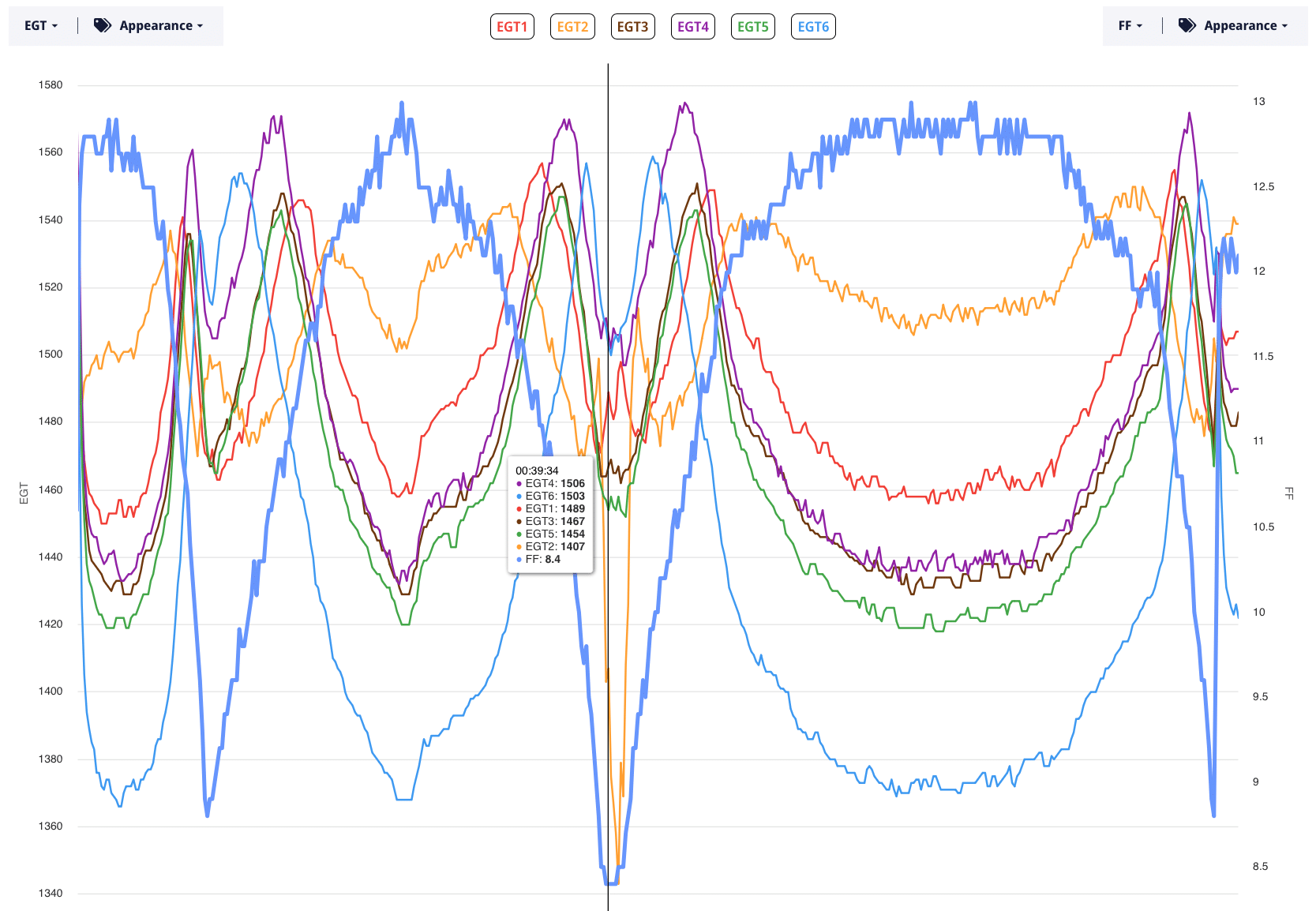

This is a test profile with a mag check and mixture sweeps starting at 30 mins. Let’s zoom into the mag check.

FF is leaned to 12 GPH at 30:45, then richened back to about 12.5, then the mag is isolated and one of the plugs misfires. So the problem with cyl 2 is weak spark – not a clogged injector?? Not so fast. We can’t reliably discern which mag is being checked at 30:45, because FF is changed before the second mag is isolated. It’s a natural reaction when the engine gets rough. Let’s look at the mixture sweeps. FF is the bold blue line.

00:37:34-00:39:34

EGT2 peaked at 11.8

EGT1 peaked at 11.1

EGT3 peaked at 10.7

EGT5 peaked at 10.7

EGT4 peaked at 10.6

EGT6 peaked at 9.8

GAMI spread is 2.0

The GAMI tool confirms 2 is first to peak, and the flameout of EGT 2 at the cursor all point to an injector clog in cyl 2. I would bet that once injector 2 is cleaned and the GAMI spread is lower, both plugs of cyl 2 will check out ok. I’m comfortable making that bet because the symptoms clearly point to an injector clog and we wouldn’t see that so clearly if a bad plug were complicating the issue.

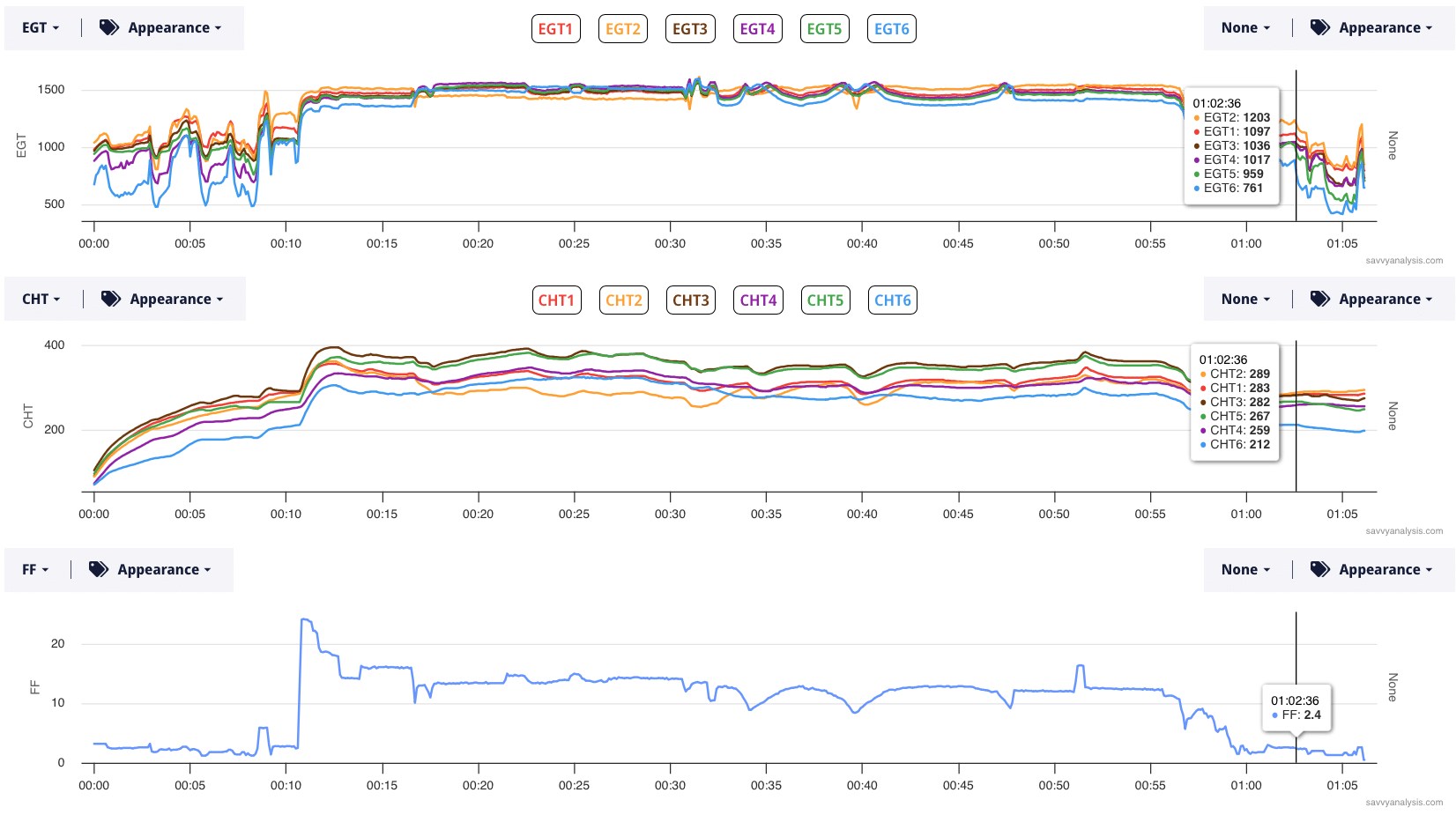

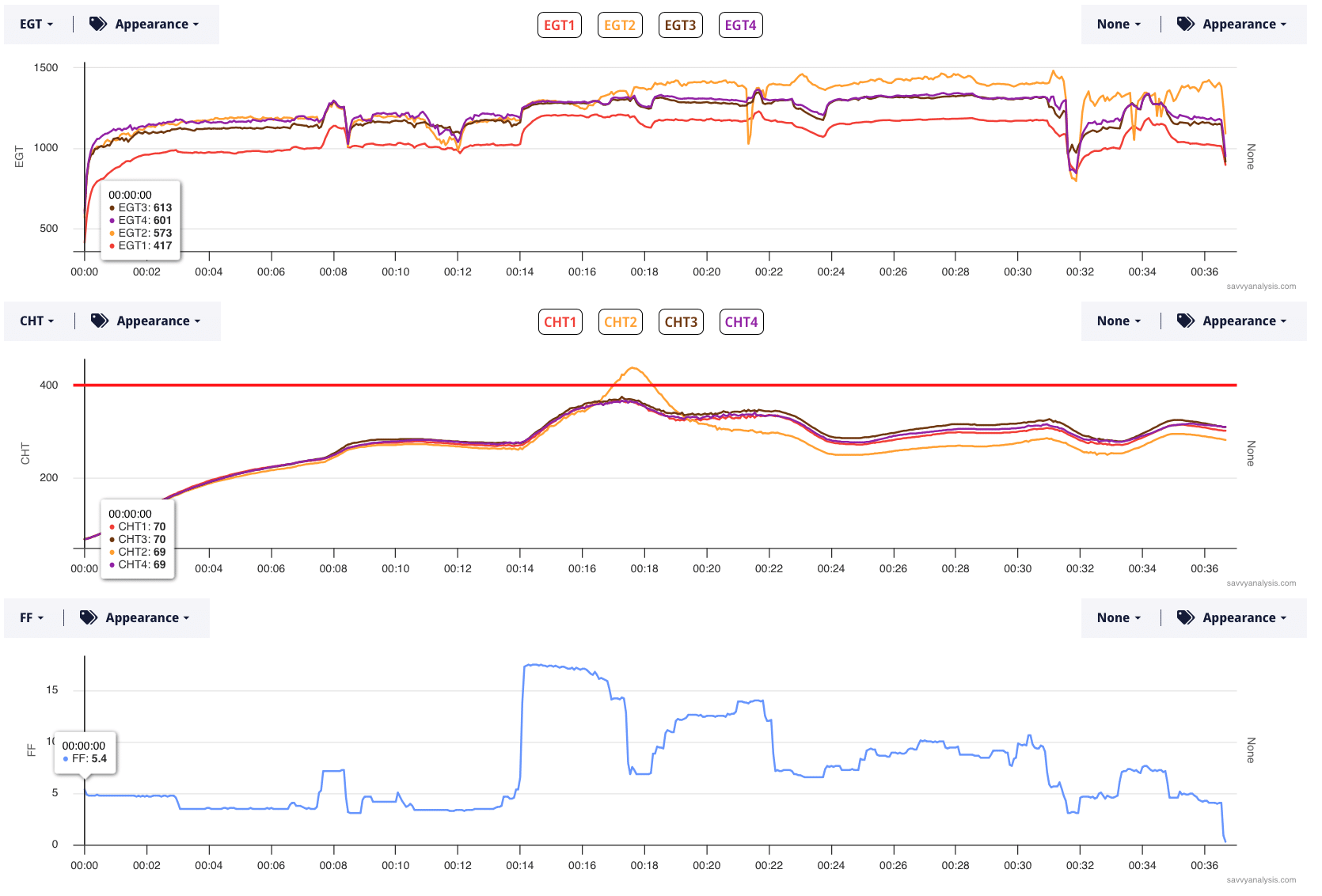

Next up is a Mooney M20J powered by a Lycoming IO-360 and data from a JPI 900 with a 1 sec sample rate. CHTs on top, with EGT’s and FF below. Nothing special about the cursor placement – just getting it out-of-the-way.

The overview shows that EGT 1 is low throughout. Meanwhile, CHT 1 looks fine. Let’s put a pin in cyl 1 for now and once the bigger problem is solved we can devote attention to why EGT 1 is low.

Takeoff is at the 14 minute mark and as the pilot is leaning during cruise climb, CHT 2 begins an excursion at the 16 minute mark. Up to then, CHT 2 had been lowest – just barely. EGT 2 rises and stays high until shutdown, except for a quick downspike at 22 mins.

This is a classic detonation pattern and was fortunately brief because of quick action by the pilot. The big drop in FF at 17 mins broke the chain and probably saved the cylinder.

In the words of the pilot from a note to Mike Busch–

While I admit it took me a bit longer than I would have liked to understand what was happening, your videos came to mind and I reduced power, fully opened the cowl flaps (from 3/4), and dropped the nose to increase airspeed. The mixture was already full rich. This broke the thermal cycle with a peak CHT of around 440 degrees (Redline is 475). I was then able to make a normal landing back at my home field with the family safe and sound. I am not sure how that situation would have turned out had I not been watching your videos, but thankfully, I didn’t have to find out.

Senior Analyst and Mooney Guru Paul Kortopates worked this ticket, as he does with all of our Mooney clients. The shop wanted to pull the cylinder but the owner – armed with advice from Paul and Mike – was able to assess the integrity of the cylinder with less intrusive measures and keep the jug flying.