If you applied the scientific method to troubleshooting a GA engine, problem, you’d isolate one variable, make an adjustment, and assess the results. But it’s not practical. In the real world with a mechanic shortage it’s hard enough to get shop time – so all but the most urgent and airworthy items get pushed to the squawk list and get dealt with at the same visit. So when the plane goes into the shop with a problem, and lots of hands with lots of tools touch lots of devices, then the airplane emerges with the same or maybe a different problem, troubleshooting gets complicated.

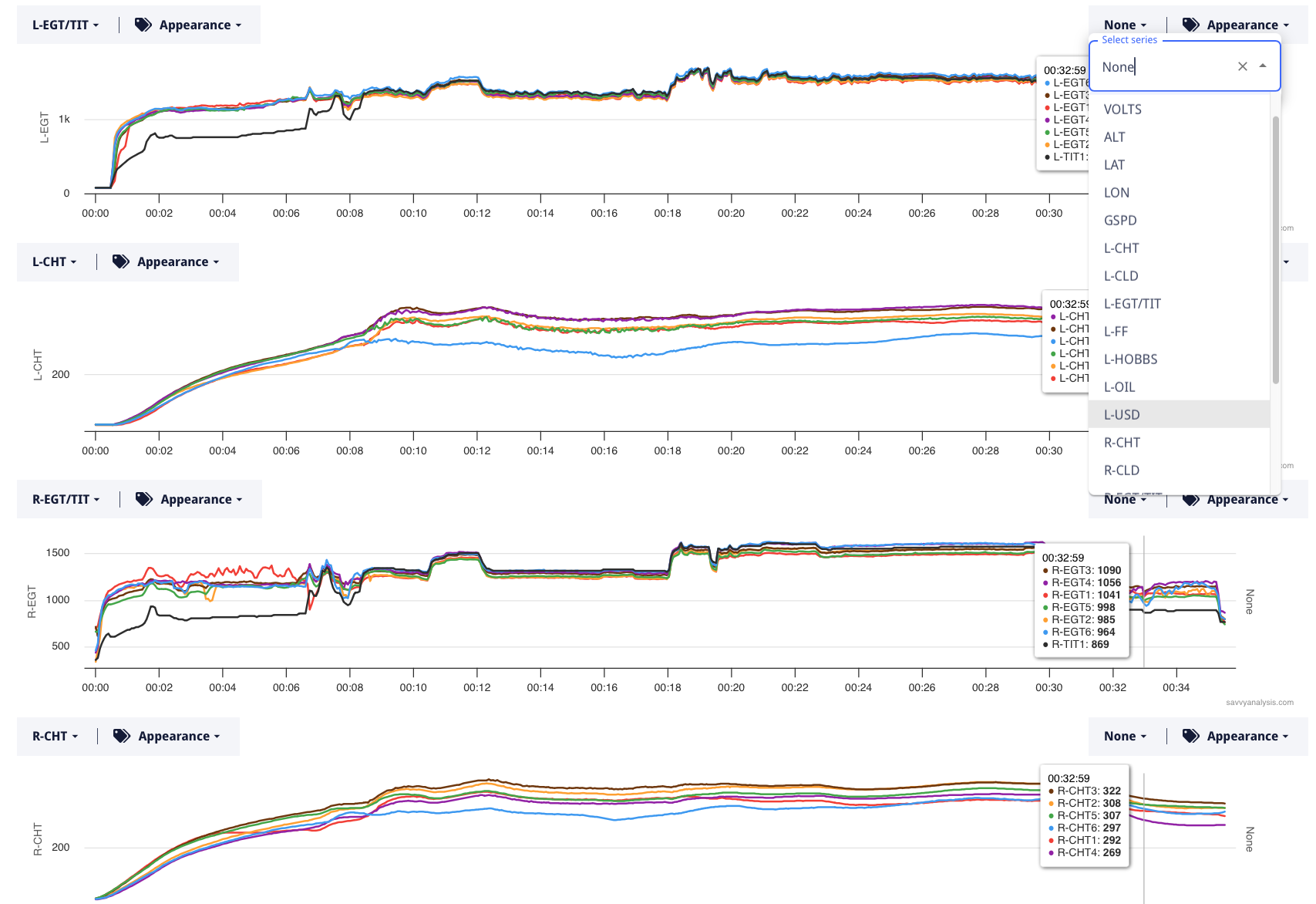

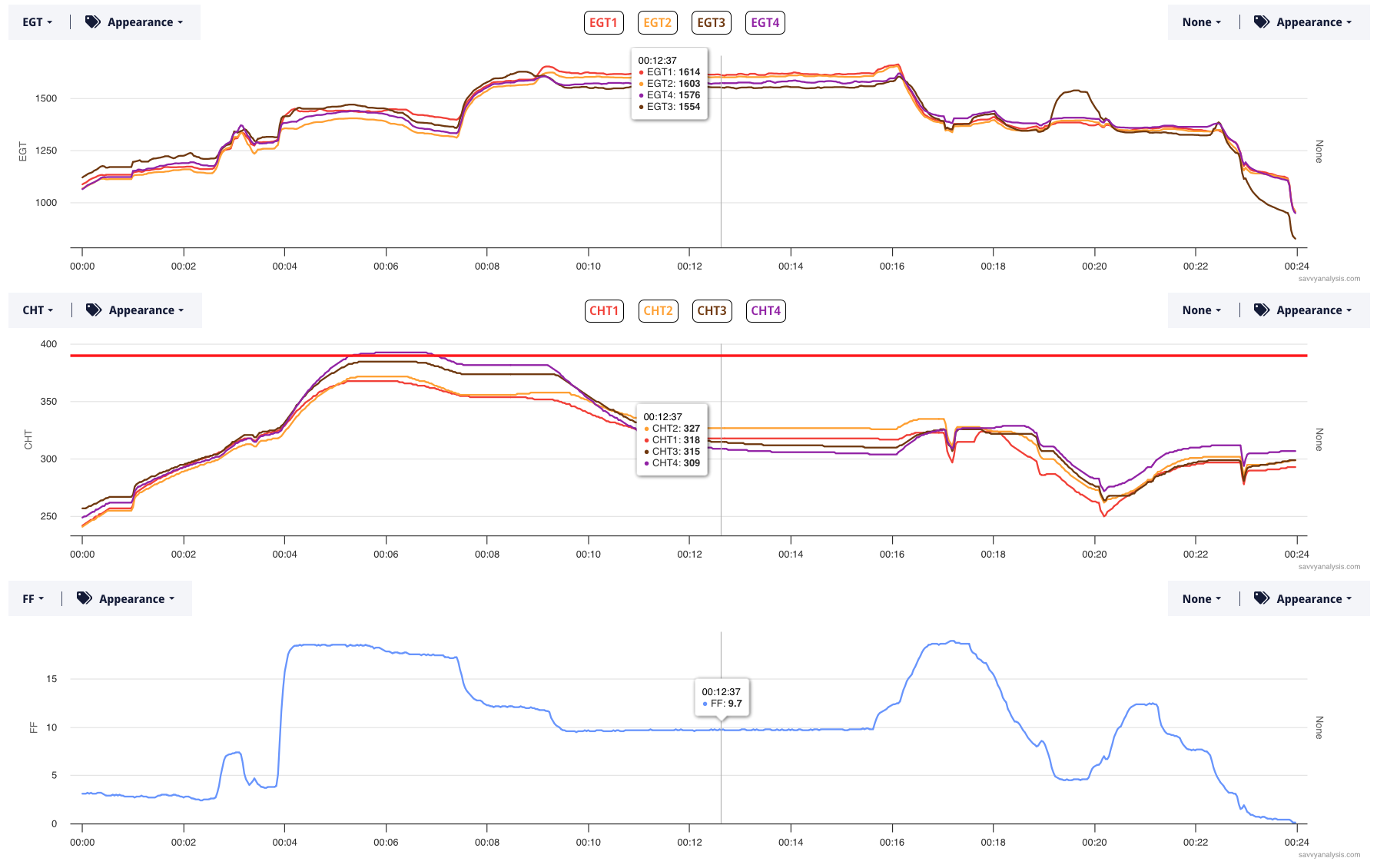

First up is a Piper Chieftain powered by Lycoming LTIO-540 engines with data from a JPI 760 Twin with a 2 second sample rate. Here are EGTs and CHTs from a typical recent flight.

Things look pretty good in cruise, but the right engine is clearly not idling well. Takeoff CHTs had been a little high so our client asked the shop to pull the fuel control unit and bump up max FF a little. After the FF nudge, the prop on the right engine was surging. Was that causing the surging?

Complicating the analysis was no RPM data from the 760 Twin. We had everything on the list on the right-side pull-down menu but not RPMs. Or MAP. When we’re troubleshooting an issue with a turbo – especially a prop surging issue – it helps to have RPMs and MAP.

My colleague Ray Eaker worked this ticket and suspected the problem wasn’t with fuel flow, and asked for data for our test profile including a LOP mag check. We didn’t even get that far before the client decided to pull the R mag and the shop reported timing retarded by 4º, worn points and the coil flunked the bench test. It worked fine at ambient temps but when heated the resistance jumped from 1 ohm to 300 ohms. Once the mag was fixed the ignition stabilized and the FF bump did help with CHTs in initial climb.

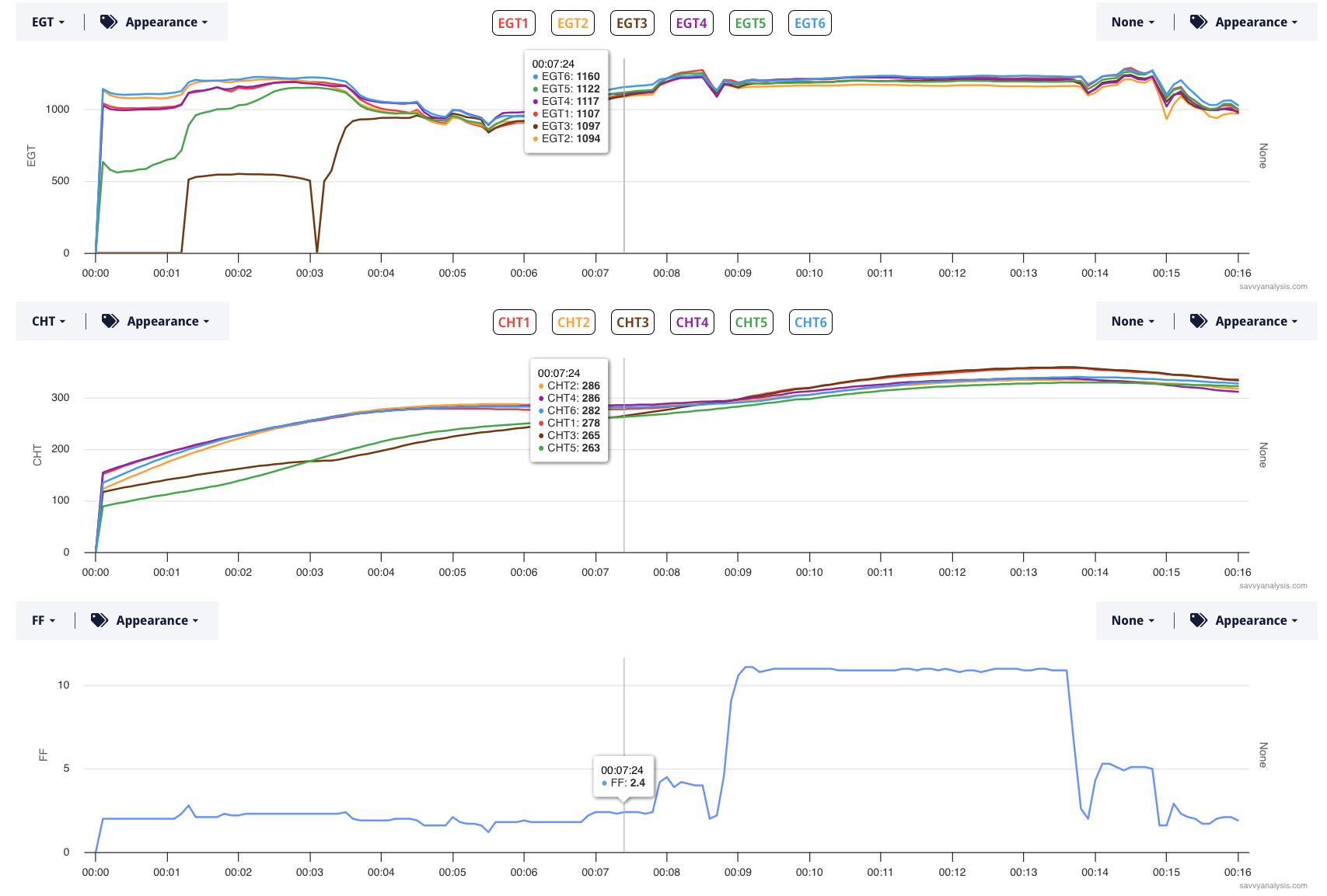

Next is a Cirrus SR20 powered by a Continental IO-360 with data from an Avidyne with a 6 second sample rate. EGTs, CHTs and FF. Nothing special about cursor placement.

The issue is sticky valves on cyls 3 and 5. The data above is a ground run after this one-hour flight below. Nothing special about cursor placement.

If you just ignore the ugliness after engine start the takeoff and cruise data look great. We found several instances of these two valves sticking, along with many instances where they didn’t stick. When they stuck they stuck at engine start and warm-up, never in climb, cruise, descent or taxi-in.

This engine had recently been overhauled. The first instance of sticking was reported during a wintertime cold start without an engine pre-heat. When the shop borescoped the cylinders they found this D-shaped gash in the piston crown.

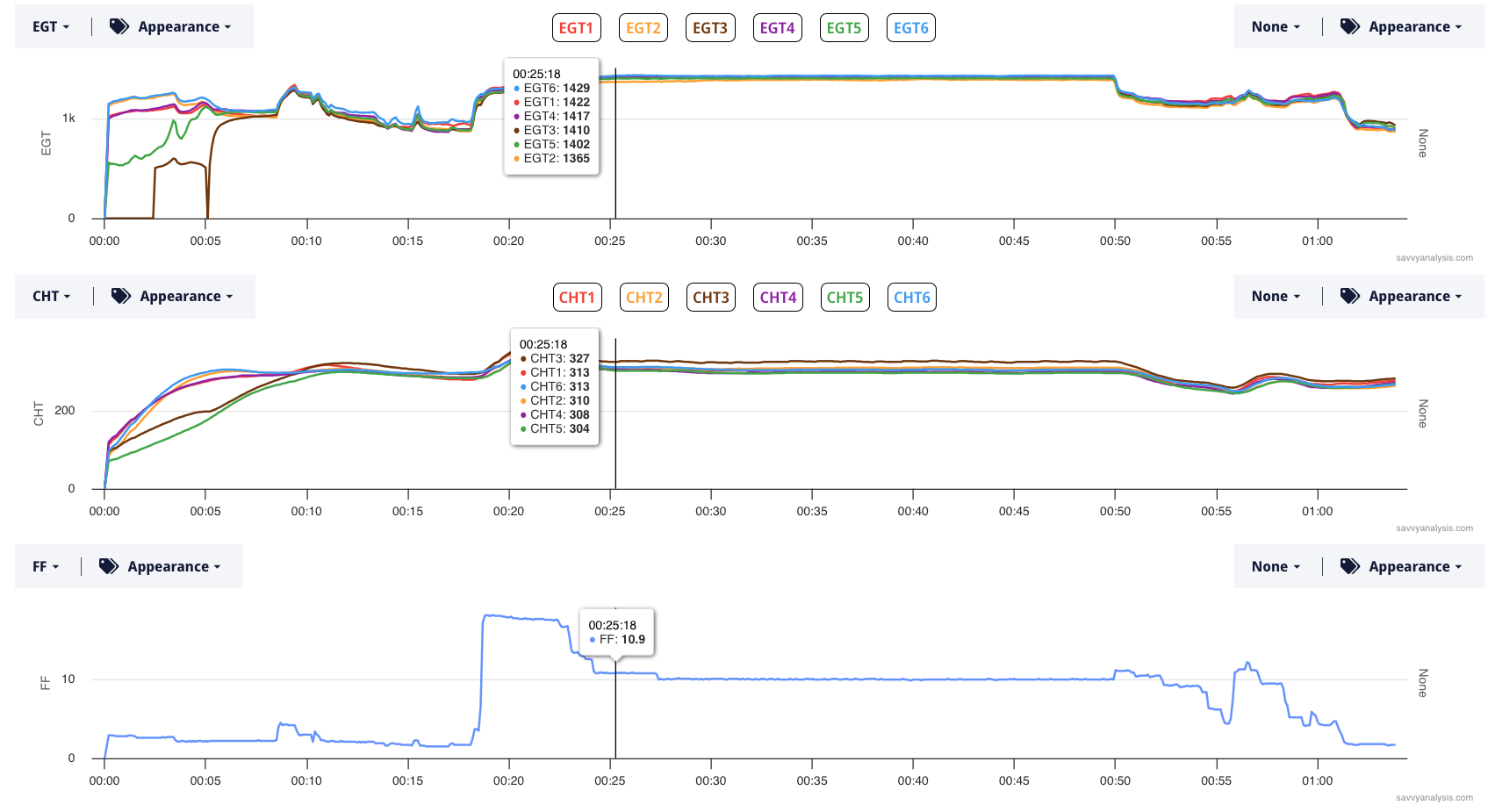

Next is data from a Piper Cherokee 180 powered by a Lycoming O-360 with data from a Garmin G3X with a one second sample rate. This is a typical cruise flight. EGT’s on top followed by CHT’s and FF. Nothing special about the cursor placement.

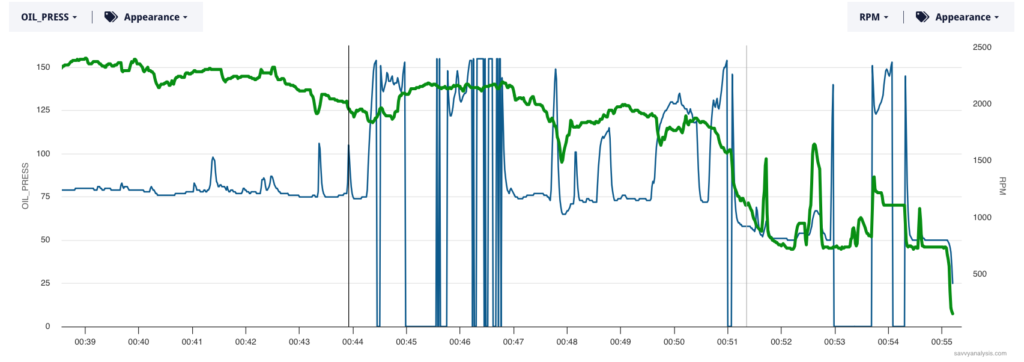

Here’s data with oil pressure in the normal range so so yeah yeah, then it starts bouncing around – including spikes up to 150 and down to zero – neither of which we trusted. When we looked at the oil pressure trace we wondered if those spikes correlated to the many power changes toward the end of the flight. Here’s oil pressure in blue and RPMs in green.

There’s a loose correlation, but they’re definitely not moving in tandem. It always makes sense to check the connection first, but with this connection, we’d expect to see spikes from normal to zero, but the up-spikes mixed in with the dropouts suggest a failing probe.

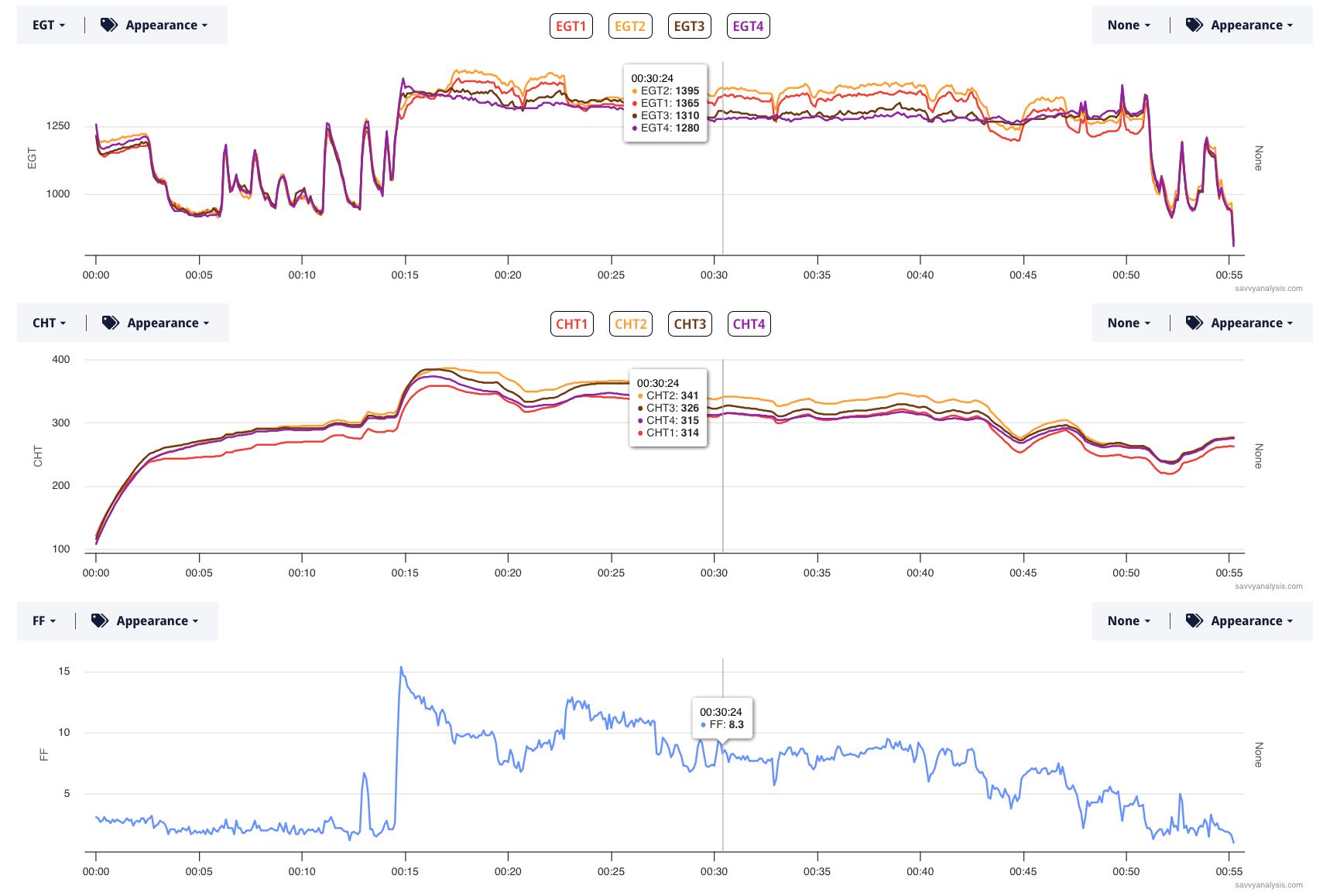

We’ll finish this month with a Lancair powered by a Superior XP IO-360 with data from a GRT 4000 with a one second sample rate. EGT’s, with CHTs and FF below.

Here’s what our client reported —

Around minute 19, my right side exhaust pipe broke in two. It made a slightly different noise (but not load or anything), and I smelled a burning smell Luckily I was close to home, and landed within 5 min. During taxi back the CO alarm went of. After shutdown I noticed the broken pipe. The fire protection tape and padding did its work very well, there is no further damage, no burned cowling, nothing. Just interesting to see that only Cyl 3 appears to be affected, Cyl 4 looks similar to 1 and 2.

We’re not surprised to see EGT 4 stay normal as EGT 3 takes its excursion.

We might expect a similar rise in EGT 1 since it’s on that side.

In fact, we see a drop in CHT 1, and that might be because outside air is getting into the exhaust system thanks to the pipe break.