When are manufacturer-specified inspection, overhaul and replacement intervals mandatory for a Part 91 operator?

“It has been six years since your propeller was last overhauled, so we’re going to have to overhaul it this year as required by Hartzell.”

“Your magnetos are past due; TCM requires that they be overhauled every four years.”

“We need to clean your fuel nozzles and adjust your fuel injection system annually as specified by the engine manufacturer.”

“The trim tab actuators need to be disassembled, cleaned and lubricated—the Cessna maintenance manual says this must be done every 200 hours.”

“The Instructions for Continued Airworthiness for your Garmin autopilot requires that the servo clutches be checked for proper breakaway torque at every annual inspection.”

“We need to pull the wing bolts on your Bonanza and send them out for non-destructive testing—Beech requires this be done every five years.”

“The regulator on your STC’d oxygen system needs to be sent out for overhaul every five years according to the manufacturer’s Instructions for Continued Airworthiness.”

I see mechanics telling my clients these sorts of things every day. An important part of my job is to advise my clients to decline most of these things because (1) they’re not required (even if the manufacturer says they are), and (2) doing them is often at best a total waste of money and at worst a good way to create a problem where none exists.

In my experience, many aircraft owners find it quite uncomfortable to say “no” to their mechanics and shops, so my clients look to me and my technical team to do that for them. No problem: We’re very comfortable saying “no.” We do it dozens of times a day.

Most of the time when we say “no” to something that a mechanic proposes to do on the basis of manufacturer’s guidance, our direction is accepted without debate. Occasionally, however, we get some resistance. That’s because as most A&P mechanics have been trained to follow manufacturer’s guidance to the letter without question. Many believe that they are required by regulation to do so.

I sometimes find it necessary to give these mechanics a bit of remedial training on exactly what the FARs do and do not require. Occasionally these discussions get interesting.

Example: Hartzell Prop TBO

Last year, for example, I found myself in an interesting dialogue with the Director of Maintenance (DOM) of a shop that was performing an annual inspection on a client’s aircraft. The shop told my client that they had to send his Hartzell propeller out for overhaul because it was six years old. The overhaul would have cost my client about $3,000, and because this was an always-hangared, actively-flown aircraft, I recommended that my client defer the overhaul for at least a few more years.

When we declined the overhaul, the DOM pushed back and opined that it was required by regulation. That surprised me, because most mechanics understand that manufacturer-specified TBOs are almost never required by regulation.

(As regular readers of this column are well aware, I’m not exactly a big fan of the TBO concept. The engines on my Cessna 310 are at 200% of TBO, and my props haven’t been overhauled for 21 years.)

When I asked the DOM to explain why he felt the overhaul was required, he responded with an interesting argument. He cited the Type Certificate Data Sheet (TCDS) for the Hartzell propeller in question. Like most such documents, this TCDS contains a series of numbered notes at the end. “Note 12” makes reference to Hartzell Service Letter HC-SL-61-61() for overhaul periods. In turn, Hartzell Service Letter HC-SL-61-61-Y (the current version) states that “Hartzell propellers installed on reciprocating engines MUST be overhauled at the intervals specified in Section 3, Overhaul Periods, Paragraph B.” For this particular prop, Paragraph B specifies an overhaul period of 2400hrs or 72 calendar months.

The DOM argued that while Part 91 operators are normally not required to comply with manufacturer’s service bulletins, the fact that this particular service bulletin HC-SL-61-61-Y is referenced by the TCDS makes compliance mandatory. This argument gave me pause, because—like most IAs—I had always been taught anything that appears in a TCDS is an airworthiness requirement. At the same time, I found it difficult to believe that the FAA really intended to make Hartzell’s propeller TBOs compulsory. So before responding to the DOM, I decided I’d better do some homework.

My homework turned up two interesting documents. One was a Letter of Interpretation sent to Hartzell in January 2008 by the head of the FAA Chicago Aircraft Certification Office (the FAA office that has direct oversight over Hartzell) specifically addressing “Note 12” in the Hartzell TCDS. This letter states in pertinent part:

“The intent of this Note [12] is to provide the end user a means to determine the proper service information for that particular propeller design. The overhaul periods are NOT mandated by this reference as the FAA-approved airworthiness limitations section (e.g., mandatory inspections of life limits) do NOT include overhaul periods. The addition of this Note does NOT mandate overhaul periods for Part 91 operators…”

My homework also unearthed FAA Order 8620.2A which specifically addresses the subject of Type Certificate Data Sheets. This Order states in pertinent part:

“A TCDS is part of a product’s type certificate (TC). A TCDS is a summary of the product’s type design. It is used primarily by authorized persons during initial or recurrent issuance of a Standard Airworthiness Certificate. It is neither a regulation, a maintenance requirements document, or a flight manual document. As such, for aircraft holding a valid and current airworthiness certificate, a TCDS should not be used as a sole source to determine what maintenance is required or what the flight operations requirements are. Any language on a TCDS, by itself, is not regulatory and is simply not enforceable.”

On the subject of TCDS Notes, Order 8620.2A states:

“Some OEM’s have placed mandatory language such as ‘shall,’ ‘must,’ and ‘will’ on their TCDS that imply that compliance with TCDS notes is mandatory. However, in the absence of regulatory language, or an AD that makes such TCDS notes mandatory, compliance with such notes is NOT mandatory.”

I shared these documents with the DOM. He reviewed them and agreed with me that the six-year prop overhaul was not required.

What is required by regulation?

Mechanics are often confused about exactly what maintenance is or is not required by regulation partly because the regulations are not terribly clear, and partly because A&P training tends to be spring-loaded to the “always do it by the book” position. There exists a large body of FAA Orders and FAA Letters of Interpretation that make it very clear what the FAA’s position is on this subject, but very few mechanics have ever read any of this stuff or received any training on the subject.

If you spend a little time studying this (as I have), it turns out that things are very simple, clear and unambiguous. Here it is in a nutshell…

Manufacturer’s guidance comes in three basic forms: maintenance manuals (MM), instructions for continued airworthiness (ICA), and service bulletins (SB). It also comes in two basic flavors: how-to’s and when-to’s. How-to’s are the responsibility of mechanics and are covered in FAR Part 43, while when-to’s are the responsibility of aircraft owners and are covered in FAR Part 91.

The FARs refer to “how-to” guidance as “methods, techniques and practices” (MTPs). The general rule is that maintenance must be done in accordance with the MTPs specified in the manufacturer’s MM or ICA or in accordance with other MTPs that the FAA finds to be acceptable. The specific regulatory reference is FAR 43.13(a) which states in pertinent part:

§ 43.13 Performance rules (general).

(a) Each person performing maintenance, alteration, or preventive maintenance on an aircraft, engine, propeller, or appliance shall use the methods, techniques, and practices prescribed in the current manufacturer’s maintenance manual or Instructions for Continued Airworthiness prepared by its manufacturer, or other methods, techniques, and practices acceptable to the Administrator, except as noted in §43.16.

An exception to this rule is that “how-to” guidance that is set forth in an FAA-approved Airworthiness Limitations Section of a manufacturer’s MM or ICA, which must always be followed exactly:

§ 43.16 Airworthiness limitations.

Each person performing an inspection or other maintenance specified in an Airworthiness Limitations section of a manufacturer’s maintenance manual or Instructions for Continued Airworthiness shall perform the inspection or other maintenance in accordance with that section…

Although the FARs provide for using alternative acceptable MTPs (except for Airworthiness Limitations), such alternative methods are rarely available. So at least 99% of the time, mechanics wind up performing maintenance using the MTPs (“how-to’s”) set forth in the manufacturer’s MM, ICA and/or SBs.

What about when-to’s?

“When-to” guidance includes manufacturer-specified inspection, overhaul and replacement intervals, as well as other manufacturer guidance about how frequently various maintenance tasks are to be performed. Virtually every aircraft maintenance manual contains a long list of scheduled maintenance tasks—things to be done every 50 hours, every 100 yours, every 12 months, etc. The maintenance manual for my Cessna 310 contains more than 250 such items.

Manufacturers of engines, propellers and appliances (e.g., magnetos, vacuum pumps, etc.) usually specify times between overhauls (TBO) or times between replacement (TBR) in MM or ICA or SBs. Lycoming, Continental, Hartzell and McCauley all set forth their engine and propeller TBOs in service bulletins.

The general rule is that Part 91 (non-commercial) operators are NEVER required to comply with such manufacturer-specified intervals (“when-to’s”) simply because there is no regulation in the FARs requiring them to do so. There are two—and only two—exceptions to this general rule: If such intervals are mandated by an FAA Airworthiness Directive (AD) or if they are set forth in an FAA-approved Airworthiness Limitations Section (ALS) of the manufacturer’s MM or ICA, then compliance is required by regulation. Otherwise, it isn’t. The regulatory reference that covers these two exceptions is FAR 91.403, which states in pertinent part:

§ 91.403 General.

(a) The owner … of and aircraft is primarily responsible for maintaining that aircraft in an airworthy condition, including compliance with Part 39 of this chapter [Airworthiness Directives].

(c) No person may operate an aircraft for which a manufacturer’s Maintenance Manual or Instructions for Continued Airworthiness has been issued that contains an Airworthiness Limitations section unless the mandatory replacement times, inspection intervals, and related procedures specified in that section … have been complied with.

Frequently-asked questions

Q: Are you saying that I can ignore all of the scheduled maintenance tasks listed in my aircraft’s maintenance manual?

A: If your maintenance manual has a clearly identified FAA-approved “Airworthiness Limitations” section (ALS), then any inspection, overhaul or replacement intervals prescribed in that section must be complied with. Intervals that appear in any other part of the maintenance manual need not be complied with. The maintenance manuals for legacy aircraft certificated under CAR 3 do not contain an ALS; those for newer-design aircraft certificated under FAR 23 typically do contain an ALS. The maintenance manuals for Lycoming and Continental engines do not contain any Airworthiness Limitations.

This doesn’t mean you should ignore all manufacturer-prescribed maintenance intervals. Some of them make sense and are worth following, although many (perhaps most) of them don’t and aren’t. Such intervals are simply recommendations, not requirements. You should feel free to accept or reject them as you see fit—except for ADs and Airworthiness Limitations, which are non-negotiable.

It makes no difference if the manufacturer uses “compulsory-sounding” words like “mandatory” or “required” or “must” or “shall.” No manufacturer has the authority to compel you to perform any maintenance task that you don’t want to do, regardless of what language the manufacturer uses. Only the FAA has that authority.

Q: Are you saying that I can ignore Instructions for Continued Airworthiness?

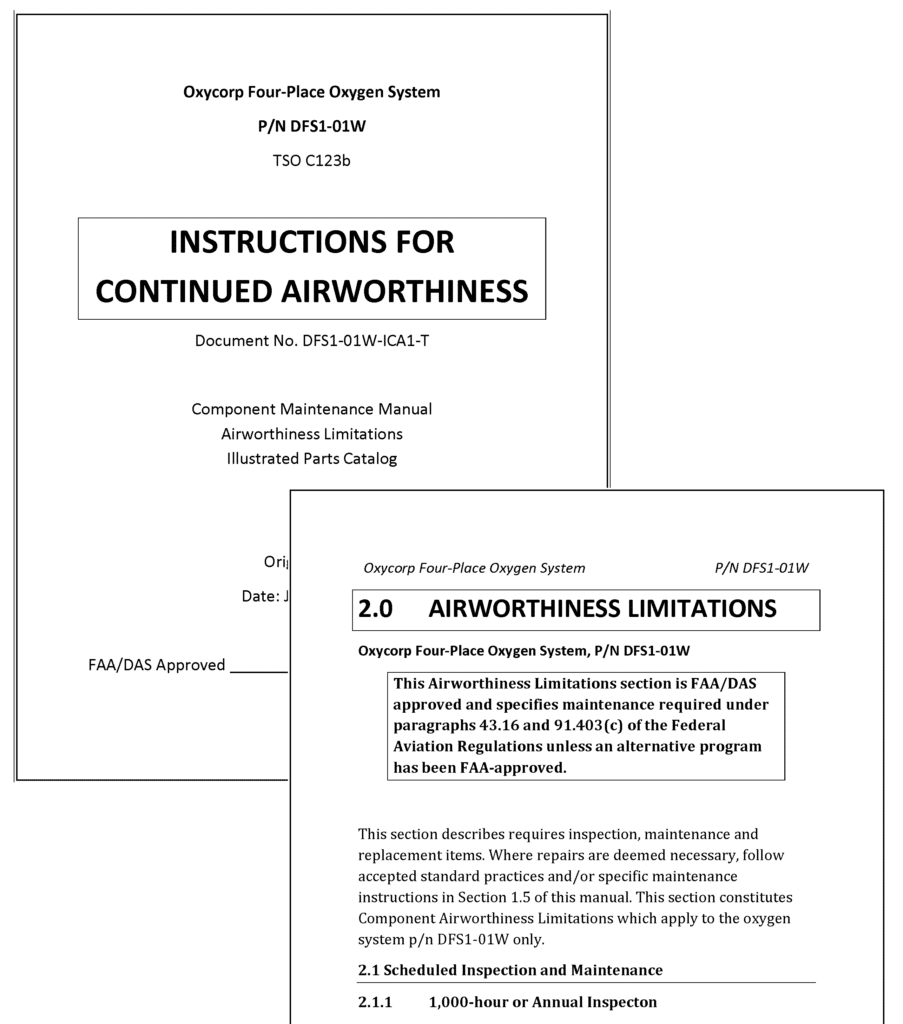

A: Yes, unless the ICA contains a clearly identified FAA-approved ALS. If it does, then any intervals prescribed in the ALS must be complied with. Intervals that appear in any other part of the ICA need not be complied with. Most ICA do not contain ALS, but some do.

Q: Are you saying that I can ignore Service Bulletins?

A: That’s exactly what I’m saying. A Part 91 operator is never required to comply with any manufacturer’s service bulletin—even those marked “mandatory” or “critical”—unless compliance is mandated by the FAA by AD. Again, I’m not saying that you should blindly ignore all SBs; some of them are quite important. I’m simply saying that whether or not you choose to comply with any particular SB is totally up to you—compliance is not required by regulation.

But my mechanic says…

So why do mechanics persist in telling their aircraft-owner customers that their engines, propellers, magnetos, trim tab actuators and oxygen regulators need to be overhauled at certain manufacturer-prescribed intervals? Usually because they believe this to be true, even though it isn’t. Every A&P is taught that manufacturer’s guidance is always to be followed meticulously and to the letter. That’s certainly what I was taught when I was studying for my A&P knowledge and practical tests. It wasn’t until I started discussing the subtleties of the FARs with the FAA lawyers at the Regulations Division of the Office of General Counsel at FAA headquarters, and studying FAA Orders and Letters of Interpretation that I discovered that most of what A&Ps (including me) have been taught about this subject is just flat wrong.

You bought a plane to fly it, not stress over maintenance.

At Savvy Aviation, we believe you shouldn’t have to navigate the complexities of aircraft maintenance alone. And you definitely shouldn’t be surprised when your shop’s invoice arrives.

Savvy Aviation isn’t a maintenance shop – we empower you with the knowledge and expert consultation you need to be in control of your own maintenance events – so your shop takes directives (not gives them). Whatever your maintenance needs, Savvy has a perfect plan for you: