Why many career A&Ps are not great troubleshooters.

I recently had a fascinating exchange with my friend and colleague Paul New. Paul is an A&P/IA and a truly extraordinary aircraft mechanic who was honored by the FAA as the National Aviation Maintenance Technician of the Year in 2007 (the year before I was so honored). But that’s where the historical similarity between me and Paul ends. While I came to aircraft maintenance rather late in life, Paul has been immersed in it since childhood, helping his A&P/IA dad with numerous aircraft restoration projects well before he was tall enough to see over the glareshield without sitting on a phone book.

In 1981, Paul earned his degree in Avionics Technology from Southern Illinois University, and spent five years managing avionics shops for a commuter airline and an FBO. In 1986, he returned to Jackson, Tenn. to work with his dad in the aircraft restoration business once again, and in 1989 he purchased Tennessee Aircraft Services, Inc. from his dad and developed it into one of the premier Cessna Service Centers in the southeast US, performing both general maintenance and major structural repairs.

Over the years, Paul and I have formed an informal mutual admiration society, and frequently bounce problems, thoughts and ideas off one another. That’s exactly what was happening when we got into the conversation I’d like to share with you.

Cessna P210 engine problem

Paul emailed me about one of his customers who had recently encountered an engine problem shortly after takeoff on a recurrent training flight (with a CFI in the right seat). The owner/pilot told Paul that at about 400’ AGL, he noted a serious overboost, five inches over MAP red-line, and throttled back to bring the MAP back to red-line. At that point, according to the pilot, the engine started running very rough. The pilot elected to put the airplane down on the crossing runway, landed long and hot with a 17-knot tailwind, and took out the chain link fence at the far end of the runway. Paul was on his way to the scene of the incident to ferry the aircraft back to his shop for repairs.

Upon hearing his customer’s tale of woe, Paul’s first thought was that the pilot may have turned on the electric boost pump for takeoff, something you’re not supposed to do in the P210. According to Paul, “Leaving on the boost pump is a common mistake in Cessna 210s, particularly with pilots who are used to flying Lycoming-powered airplanes where turning on the boost pump for takeoff is SOP.”

Show me the data!

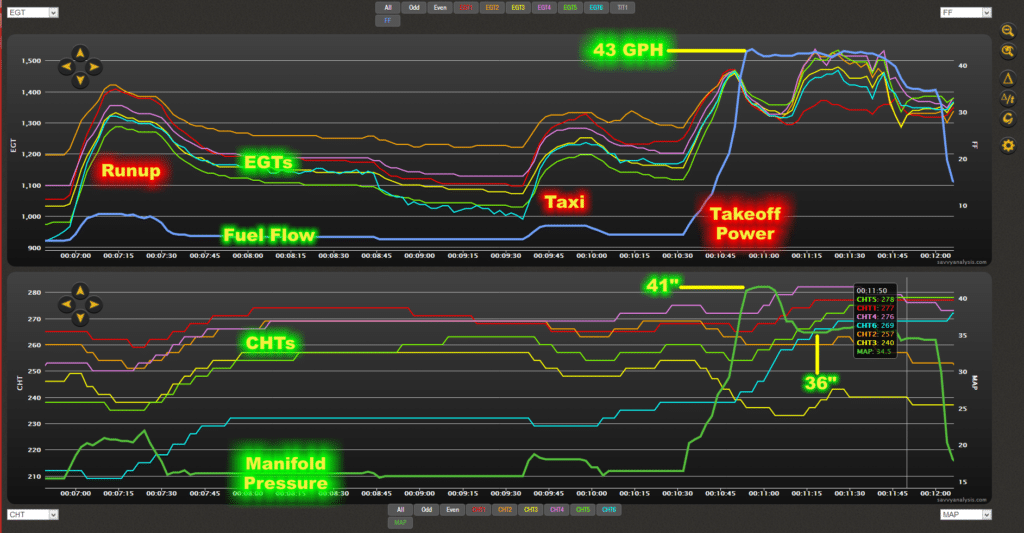

Paul arranged for his customer to dump the data from the P210’s JPI EDM-830 digital engine monitor data and to upload it to the SavvyAnalysis.com website. (See Figure 2.) Paul asked whether I’d be willing to take a look at it and give him my impressions, and I told him I’d be happy to do that.

When I looked at the engine monitor data, it seemed to tell a very different story than the one that the pilot had related Paul. I couldn’t see any evidence that the pilot flooded the engine by using the electric boost pump; the fuel flow data looked normal. Nor could I see any evidence that the pilot throttled back the engine (as he told Paul he’d done), because throttling back would have reduced fuel flow and the engine monitor recorded no reduction in fuel flow. What the data indicated was simply that the wastegate stuck closed on takeoff (causing the overboost) and then subsequently unstuck, reducing MAP to what it was supposed to be without any pilot input.

I also observed that while five of the six CHTs were rising as expected after takeoff power was applied, the CHT for cylinder #3 was falling, suggesting that cylinder #3 wasn’t making full power. If one cylinder wasn’t making full power, that would certainly account for the engine running rough. My diagnosis was that something went wrong with cylinder #3 after takeoff—maybe a clogged fuel nozzle, maybe a stuck valve—that caused the engine to run rough and scared the pilot into making a hasty and poorly executed downwind landing. In reporting this to Paul, I added that “when confronted with significant dissonance between what a pilot reports and what an engine monitor reports, I’m inclined to believe the engine monitor.”

Do mechanics know too much?

Paul’s reply intrigued me:

Mike, thanks for the analysis. I agree with your diagnosis. But what I find most telling is the difference between my “mechanic’s analysis” and your “analyst’s analysis.” At the end of the day, I think like a career mechanic with decades of history crammed into my head, and my experience as a mechanic prejudices my view. Because the pilot’s account of events made me think of many occasions when Lycoming pilots get into a Continental airplane and turn on the electric fuel pump for takeoff, I was already spring-loaded to look for information to support this hypothesis.

My takeaway from this is that I—and I believe career mechanics in general—are the wrong people to analyze engine data. Career mechanics carry too much mental baggage to be effective as analyst. What I see mechanics not doing well is “connecting the dots” to analyze an unusual event. It also occurs to me that we mechanics might do better if we looked at the engine monitor data first before we talk to the pilot. I think that would help us to evaluate the data more objectively.

Of course, I’m also a mechanic, but I don’t consider myself a “career mechanic” like Paul. I haven’t been working on airplanes since before puberty the way Paul has, and I’ve never made my living swinging wrenches the way Paul does. I don’t have those decades of real-world experiences crammed into my brain, so I tend to analyze things more “from first principles” while career mechanics like Paul tend to analyze them through “pattern matching” against the historical library in their noggins.

Thinking, fast and slow

In his 2011 book Thinking, Fast and Slow, Nobel laureate Daniel Kahneman postulates that the human brain operates in two fundamentally different modes:

- System 1 thinking: Operates automatically and quickly with little or no effort. It is fast, intuitive, emotional, and subsconscious.

- System 2 thinking: Operates deliberatively and requires conscious effort. It is slow, rational, logical and calculating.

A student pilot relies on controlled System 2 thinking, requiring focused concentration on performing a sequence of operations that require considerable mental effort and are easily disrupted by distractions. In contrast, an experienced pilot, relying on automatic System 1 thinking, can carry out the same tasks efficiently while engaged in other activities (such as talking to ATC or calming a nervous passenger). Of course, the pilot can always switch to more conscious, focused and deliberative System 2 processing when he deems that to be necessary, such as when encountering challenging weather conditions or dealing with equipment failure.

Similarly, career A&P mechanics rely primarily on fast, automatic System 1 thinking. (Imagine what your maintenance invoice totals would be if they didn’t!) The more experience a mechanic has, the better his System 1 skills become. This works most of the time, but it can break down when a challenging troubleshooting problem demands switching to slow, deliberative, thoughtful, logical System 2 thinking. Career mechanics often don’t have the time or training to flip that switch.

System 1 thinking is fast and easy and economical and even magical at times. The problem is that sometimes it yields the wrong answer. Consider this simple problem:

A bat and a ball together cost $5.50. If the bat costs $5 more than the ball, what does the ball cost?

Most people who look at that problem find that an answer—50 cents—pops into their mind immediately, effortlessly and without any conscious calculation. It’s intuitive, not reasoned.

It’s also wrong. The correct answer is 25 cents. To get the correct answer, most people have to consciously switch into “System 2 mode” and recognize that this is an algebra problem:

x + y = $5.50

x = y + $5.00

y = ???

Presented in that fashion, most people get the right answer. But such problems generally do not announce themselves as algebra problems. It takes training and skill to recognize when the mental switch needs to be flipped.

I attribute my skill as a troubleshooter largely to my training as a mathematician and my 30-year career as a professional software developer, both fields that deal with complex abstraction and absolutely demand strong System 2 thinking. At SavvyAnalysis.com, none of our engine data analysts are A&P mechanics. One is a genomics researcher, another is an aeronautical engineer, and yet another is an award-winning music composer—all fields that require a great deal of System 2 thinking. It’s rare to find career A&P mechanics with these sorts of backgrounds.

Other professions—notably medicine and education—recognize that diagnosis and therapy (or troubleshooting and repair, if you prefer) are dramatically different activities that require dramatically different skill sets. We don’t expect our neurosurgeons to interpret CT scans or analyze tissue samples or evaluate blood labs—we rely on radiologists, pathologists and hematologists for those things.

Similarly, I think it’s high time that we stopped relying on career A&P mechanics—who are basically aircraft surgeons—to troubleshoot difficult problems, and started recognizing “A&P diagnostician” as an aviation maintenance specialty.

You bought a plane to fly it, not stress over maintenance.

At Savvy Aviation, we believe you shouldn’t have to navigate the complexities of aircraft maintenance alone. And you definitely shouldn’t be surprised when your shop’s invoice arrives.

Savvy Aviation isn’t a maintenance shop – we empower you with the knowledge and expert consultation you need to be in control of your own maintenance events – so your shop takes directives (not gives them). Whatever your maintenance needs, Savvy has a perfect plan for you: