“To err is human…” but when humans make mistakes working on aircraft, bad things can happen.

During the century since the Wright Brothers first flew, the predominant perpetrator in aircraft accidents has shifted dramatically from machine to human. Today, human error is responsible for about 90% of aircraft accidents and incidents.

It’s not that people have become more careless, forgetful, inattentive or reckless. It’s that aircraft and aircraft components have become much more reliable. As component failures become fewer and fewer, human failures represent an ever-increasing percentage.

Most of the efforts of the aviation research community have focused on errors committed by pilots. This is appropriate, since 75 to 80 percent of serious aviation accidents are due to pilot error. Yet roughly one-eighth of accidents are still caused by maintenance errors, and many of those are serious ones, sometimes fatal.

In the wake of the 1988 explosive decompression of Aloha Flight 243 and the 2000 fatal stab-trim-jackscrew crash of Alaska Flight 261—there has been an increased focus on maintenance errors by the airlines. But in my view, not nearly enough attention has been given to maintenance errors in general aviation, where the incidence of maintenance-induced failures is more prevalent.

Kinds of maintenance errors

Maintenance errors can be divided into two broad classes: (1) introduction of a problem that was not there before the maintenance began (or what I call a “maintenance-induced failure” or MIF), and (2) failure to detect a pre-existing problem during maintenance inspections.

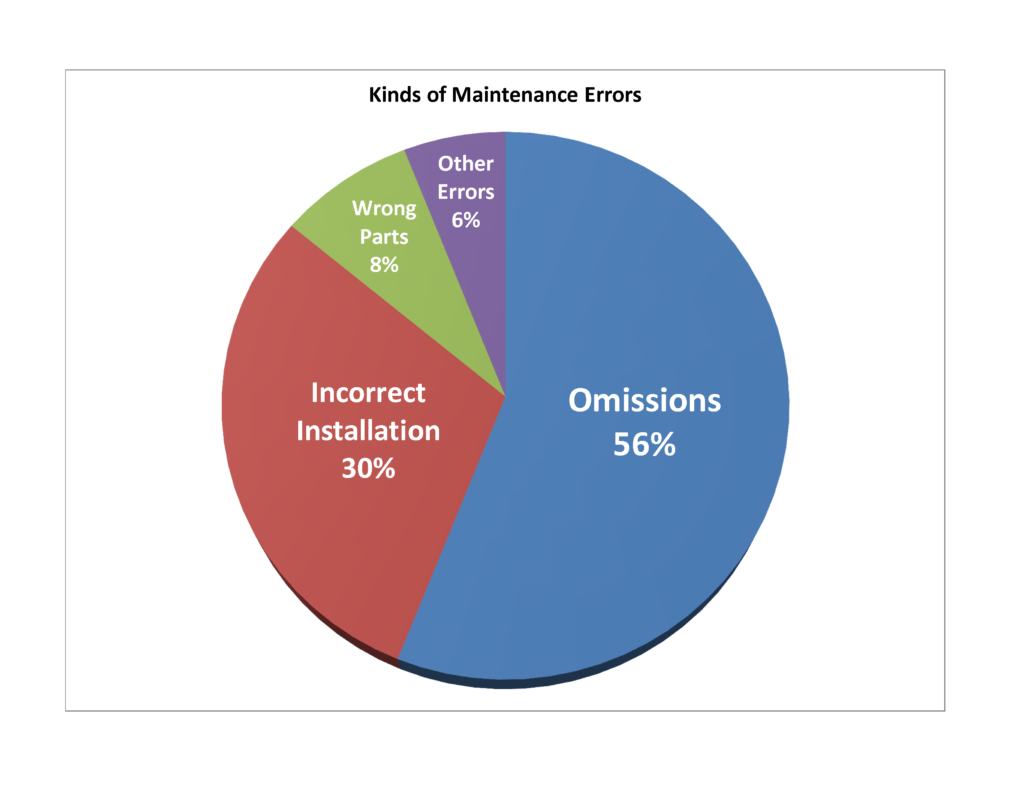

Errors of omission seem to be the most common kinds of maintenance errors. An analysis of 122 maintenance errors detected by a major airline over a three-year period revealed that 56% were omissions, 30% were incorrect installation, 8% were wrong parts installed, and 6% were other things.

My experience in general aviation suggests that we suffer the same kinds of MIFs as the airlines do, and that the majority are errors of omission. This includes things like fasteners left uninstalled or improperly torqued, caps and inspection plates left loose or missing, hoses and electrical harnesses left disconnected, and so forth.

The reassembly problem

Most maintenance errors occur not when taking something apart, but rather when putting that something back together. There’s a good reason for this. Consider a bolt onto which eight nuts have been assembled, each one labeled with a unique letter A through H:

Assume that the task at hand is to disassemble the nuts from the bolt, clean them, and then reassemble them in the original order. There is really only one way to take this assembly apart, but there are 40,320 different ways in which it could be put back together…and 40,319 of them are wrong!

This simplistic example illustrates the fact that the task of disassembly usually constrains you to one particular sequence, with each succeeding step being prompted by the last. You don’t require much guidance, because the disassembly procedure is usually obvious. In contrast, correct reassembly usually requires knowledge—either in your memory or in the form of written instructions.

Human memory being as imperfect as it is, reassembly based on memory is inevitably error-prone. Reassembly based on written guidance (such as a checklist or maintenance manual instructions) is far more reliable, but people doing a hands-on grease-under-the-fingernails job tend to be reluctant to consult written instructions. Watch any A&P work on an aircraft—including yours truly—and note how rarely he consults the manual or any other form of written guidance.

Reassembly-by-memory is probably adequate for a task that one does every day. But some maintenance tasks aren’t like this, and we all know—especially if we’re pilots—just how easily we can forget the details of a task after even a relatively short period of time.

To make matters worse, improper assembly is not always obvious on later inspection. The absence of washers, bushings, fasteners, seals, O-rings, caps, lubrication, and the like are often concealed after reassembly. Thus, reassembly-by-memory often creates the opportunity for double jeopardy: an increased probability of forgetting something important during reassembly, and a decreased probability of detecting the error once the job is done.

Slips, mistakes, and violations

Failures to perform a task as planned are commonly termed slips, lapses, trips or fumbles. “Slips” occur when one is trying to do the right thing, but screw it up somehow. Slips can be caused by omitting some necessary action, performing some necessary action in a clumsy fashion, performing some unwanted action, or carrying out the right actions in the wrong order. Such slips most often occur when doing tasks by memory—often well-practiced tasks that are done frequently in an automatic fashion.

“Mistakes” are higher-level failures caused by an error in the plan itself. These are usually caused by lack of knowledge, and occur most commonly when performing tasks that are not done very often. Often, mistakes are caused by trying to do something by memory that should have been looked up in the manual. Forgetting to torque a cylinder hold-down nut is a slip; torquing it to the wrong torque value is a mistake.

“Violations” are deviations from standard practices, rules, regulations, or standards. While slips and mistakes are unintentional, violations are usually deliberate. They often involve cutting corners in order to take the path of least resistance, and can become part of one’s habit pattern.

In a recent post to the AOPA Opinion Leaders Blog, I wrote about an incident in which the pilot of a Cessna 340 launched into IMC on the first flight after maintenance, only to discover that his airspeed indicator, altimeter and VSI stopped working as the aircraft climbed through 3,000 feet while in the clag. The cause of the problem turned out to be the failure of an avionics technician to reconnect a static line that had been disconnected to facilitate access to some panel-mounted avionics. The technician’s failure to reconnect the static line was an inadvertent slip: He simply forgot. On the other hand, his failure to perform a static system leak check after opening the static system was a (presumably deliberate) violation of FAR 91.411(a)(2). Because of the violation, the slip went undetected and jeopardized safety of flight.

Distractions

Distractions can play a big part in errors of omission. A common scenario is that a technician installs some fasteners finger-tight, then gets a phone call or goes on lunch break and forgets to finish the job by torqueing the fasteners. I have personally seen some of the best, most experienced A&P/IAs I know fall victim to such seemingly rookie mistakes—not to mention myself—so I know that they can happen to anyone. I also know of several fatal accidents and countless less-serious incidents and precautionary landings (not to mention pissed-off aircraft owners) caused by such omissions. Unfortunately, they’re a fact of life.

Just as pilots need a “sterile cockpit” during high workload phases of flight, maintenance and avionics technicians need a distraction-free workplace when performing safety-critical tasks. Unfortunately, it has been my observation that the typical piston GA shop is a distraction-rich environment. Phone calls come in. Customers drop by unexpectedly. UPS and Fedex drivers deliver anxiously-awaited parts. The Snap-On tool truck stops by. The shop’s FAA principal maintenance inspector pays an unexpected visit. The roach coach arrives with lunch.

Distractions seem to be less of a problem in the big repair stations where there’s usually a full-time Parts Manager to deal with deliveries, a Customer Service Manager to handle customer visits and phone calls, and sometimes even a Compliance Manager to interface with the FAA. But in the smaller shops that owners of piston GA usually use, employees usually wear multiple hats and must deal with these distractions as they come. That can lead to mistakes.

Big maintenance, repair and overhaul (MRO) facilities aren’t immune to distractions, either. Often such shops have multi-shift operations, and that creates its own issues. Whenever a task is handed off from one technician to another at shift change, there’s always the potential that something will be lost in the shuffle.

Quality Assurance

I’ve visited quite a few GA aircraft and engine factories over the years—the Beech, Cessna, Cirrus, Continental, Hartzell and Lycoming factories come to mind—and watched how they build our flying machines and their powerplants. One of the fundamental work rules I’ve observed at all these facilities is that there must always be at least two sets of eyes that look at every step of the process: the technician that performs the work, and an inspector who verifies that the work has been done properly. Often, there are three sets of eyes: two technicians who work as a team and check one another’s work, and then an inspector who re-checks the work. (Although as we’ve seen, even careful post-reassembly inspection cannot always detect errors and omissions made during reassembly.)

Large repair stations that work on turbine aircraft—such as the big Citation Service Center in Wichita that I’ve visited a few times—typically have similar rules, where designated inspectors are required to check the work of each technician and sign it off. But the smaller shops where most piston GA maintenance is done seldom can afford the luxury of having dedicated inspectors on staff. One technician will sometimes ask another to check a particularly critical or complex task, but most maintenance is checked by just one set of eyes belonging to the person who did the work, and most scheduled inspections are done by just one IA. Fewer sets of eyes inevitably means that more slips, mistakes, violations and discrepancies escape detection.

The owner as final inspector

Aircraft owners and pilots need to understand that maintenance errors create a significant hazard, and act accordingly. The most likely time for an aircraft to suffer a mechanical problem is on the first flight after maintenance. Prudence demands a post-maintenance test flight every time the aircraft comes out of the shop. The test flight should be done in VMC, without passengers, and in a place where the pilot can easily put the airplane back on the ground if something isn’t right.

Prior to the test flight, the owner or pilot should conduct an extraordinarily thorough preflight. Make sure that all inspection plates and fairings are installed and secure, all cowling fasteners are tight, and all fuel and oil caps installed. Check that all flight controls and trim systems are free throughout their full range of motion and operating in the correct direction. Check that all instruments and avionics systems are functioning properly. Perform a ground test of the autopilot. Run up the engine thoroughly, then shut down and check for leaks. Be sure you don’t smell fuel or anything burning.

In short, be thoroughly skeptical any time an aircraft comes out of maintenance. Your pre-flight and test flight are the last line of defense against maintenance errors.

You bought a plane to fly it, not stress over maintenance.

At Savvy Aviation, we believe you shouldn’t have to navigate the complexities of aircraft maintenance alone. And you definitely shouldn’t be surprised when your shop’s invoice arrives.

Savvy Aviation isn’t a maintenance shop – we empower you with the knowledge and expert consultation you need to be in control of your own maintenance events – so your shop takes directives (not gives them). Whatever your maintenance needs, Savvy has a perfect plan for you: