“Autographing a lie” is the worst FAR violation a mechanic can commit

By Mike Busch | A&P/IA

An IA is an experienced A&P mechanic who—by virtue of having earned an Inspection Authorization—is empowered by the FAA to make aircraft airworthiness determinations in connection with annual inspections and major repairs and alterations. This is a weighty responsibility that IAs take very seriously. The late, legendary Bill O’Brien—who for many years served as the most senior mechanic in the FAA—once described the role of an IA as “a one-man FAA-Approved Repair Station.”

From time to time, IAs find themselves facing tricky situations. That was certainly the case with one IA from Utah—let’s call him Rick—who recently contacted me for advice. Rick was halfway through a routine annual inspection on a 1982 Cessna 172 when he learned something that created a dilemma for him.

As Rick related it to me, he was having a chat with a friend—let’s call him Fred—who is also an IA and whose shop is right next door to Rick’s. When Rick mentioned to Fred that he was doing an annual on this particular 172, Fred said that he was familiar with the airplane. Some months earlier, the Skyhawk’s owner had brought the airplane to Fred and asked him to dress out some propeller damage. Fred inspected the Skyhawk’s fixed-pitch prop and informed the owner that the damage was substantial, apparently the result of a prop strike, and the propeller was unrepairable.

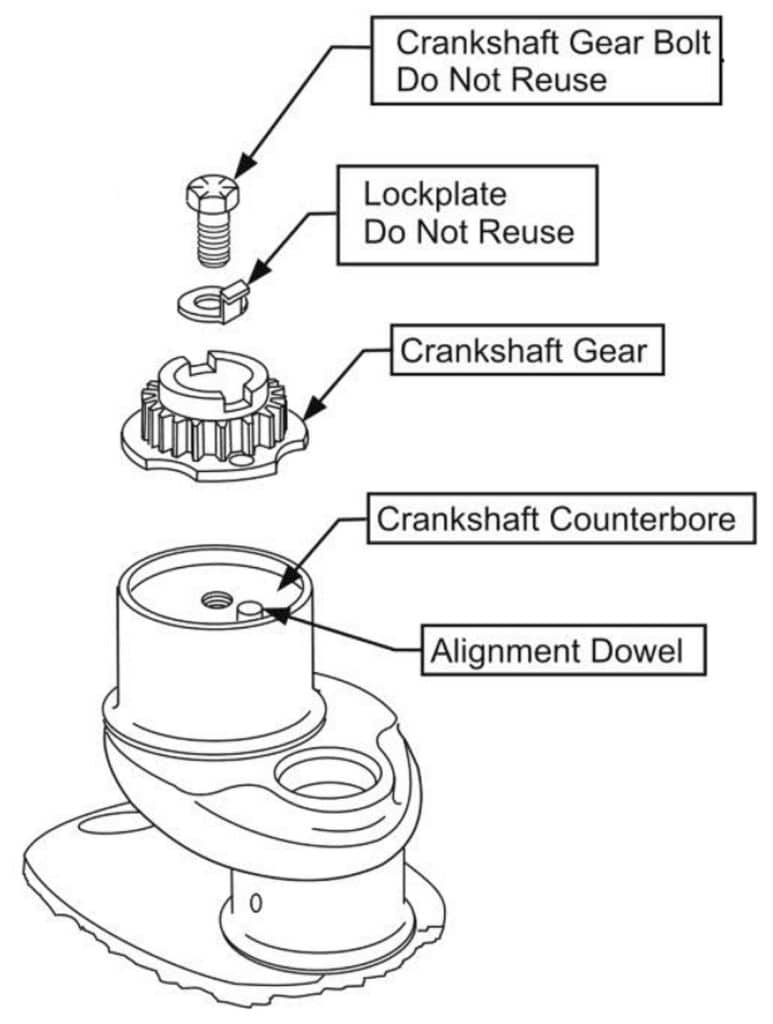

Fred further advised the owner that the Skyhawk’s Lycoming O-320 engine was subject to Airworthiness Directive AD 2004-10-14, which mandates inspection of the crankshaft gear and replacement of the crankshaft gear retaining bolt and lockplate after any prop strike before further flight. This involves removing the engine from the airplane, stripping it of accessories, and removing the accessory case to gain access to the crankshaft gear bolt. So, it’s a pretty big deal.

The AD explicitly defines a prop strike as:

(1) Any incident, whether or not the engine is operating, that requires repair to the propeller other than minor dressing of the blades; or

(2) Any incident during engine operation in which the propeller impacts a solid object that causes a drop in revolutions per minute (RPM) and also requires structural repair of the propeller; or

(3) A sudden RPM drop while impacting water, tall grass, or similar yielding medium, where propeller damage is not normally incurred.

Based on this definition, Fred reasonably concluded that the Skyhawk had experienced a prop strike.

Lycoming Mandatory Service Bulletin MSB 533C recommends doing a complete engine teardown after any prop strike—a very big deal—but compliance with service bulletins (even so-called “mandatory” ones) is not required by regulation for non-commercial operators. By contrast, compliance with the AD is compulsory.

The Skyhawk owner was not at all happy with Fred’s assessment and removed his airplane from Fred’s shop. A few months later, the owner’s newly-hired pilot brought the Skyhawk back to Fred’s shop sporting a nice new propeller and asked Fred to do an annual inspection. Fred asked the pilot if a prop strike inspection had been done to the Skyhawk’s engine, to which the pilot innocently replied, “What prop strike?” At this point, Fred smelled a rat and politely declined to perform the annual inspection.

A few weeks later, the owner’s pilot brought the Skyhawk to Rick’s shop for an annual inspection. Not knowing any of this backstory, Rick accepted the job and began inspecting the airplane. Halfway through the inspection, Rick happened to chat with Fred and learned about the damaged propeller. Rick immediately went over the Skyhawk’s maintenance logbooks with a fine-tooth comb. He found an entry documenting the installation of a new propeller, but nothing at all about a teardown inspection per Lycoming MSB 533C and nothing showing crankshaft gear bolt replacement required by AD 2004-10-14. The pilot once again denied any knowledge of a prop strike.

Rick didn’t know what to do. By all appearances, the Skyhawk was airworthy. Rick’s inspection revealed no physical evidence of a prop strike. There was nothing in the logbooks to indicate such an occurrence, nor should there have been—the FARs require that logbook entries provide only “a description of work performed” and never a description of discrepancies found.

Rick would have been quite comfortable signing off the annual inspection as airworthy had it not been for the happenstance of learning about the damaged propeller and evident prop strike during his conversation with Fred. But now that he knew what he knew, could he ignore it and sign off the annual?

My advice to Rick

I advised Rick that given what he’d learned about the history of the Skyhawk, I couldn’t see how he could sign off the aircraft as airworthy without “autographing a lie”—the worst regulatory offense that a mechanic can commit—in violation of FAR 43.12:

§ 43.12 Maintenance records: Falsification, reproduction, or alteration.

(a) No person may make or cause to be made:

(1) Any fraudulent or intentionally false entry in any record or report that is required to be made, kept, or used to show compliance with any requirement under this part;

(2) Any reproduction, for fraudulent purpose, of any record or report under this part; or

(3) Any alteration, for fraudulent purpose, of any record or report under this part.

(b) The commission by any person of an act prohibited under paragraph (a) of this section is a basis for suspending or revoking the applicable airman, operator, or production certificate, Technical Standard Order Authorization, FAA-Parts Manufacturer Approval, or Product and Process Specification issued by the Administrator and held by that person.

Doing so would not only place Rick’s IA certificate at risk of revocation, but also his A&P mechanic certificate and any other FAA certificates he holds. I counseled him that he could not go there.

My suggestion to Rick was to contact the owner of the Skyhawk and offer him three alternative options:

- Consent to having the AD 2004-10-14 crankshaft gear bolt replacement performed as a precondition to obtaining Rick’s airworthy signoff of the annual inspection; or

- Instruct Rick to complete the annual inspection and sign it off as unairworthy with a discrepancy list indicating that AD 2004-10-14 had not been complied with.

- Instruct Rick to stop work on the annual inspection, pay him for the time he’d expended so far, and remove the airplane from Rick’s shop with no logbook entry documenting the inspection. (There’s an FAA Advisory Circular advising that mechanics are supposed to complete an inspection once they start it, but it’s non-regulatory.)

I cautioned Rick against writing anything about a prop strike in the Skyhawk’s logbooks. I reminded him that mechanics aren’t supposed to document discrepancies in an aircraft’s permanent maintenance records, nor to act like the “safety police” by trying to compel aircraft owners to do the right thing. I further suggested that if the owner chose option number two and asked Rick to assist him in obtaining a ferry permit from the local FSDO to fly the airplane to another shop at another airport, Rick should agree to do so.

After weeks of silence, curiosity overcame me. I reached out to Rick inquiring about how his dilemma was ultimately resolved. Rick replied that after he had a long talk with the owner’s pilot, they agreed to “do the right thing” by having the full MSB 533C prop-strike teardown inspection performed (perhaps after learning that it would be fully paid for by insurance).

You bought a plane to fly it, not stress over maintenance.

At Savvy Aviation, we believe you shouldn’t have to navigate the complexities of aircraft maintenance alone. And you definitely shouldn’t be surprised when your shop’s invoice arrives.

Savvy Aviation isn’t a maintenance shop – we empower you with the knowledge and expert consultation you need to be in control of your own maintenance events – so your shop takes directives (not gives them). Whatever your maintenance needs, Savvy has a perfect plan for you: