We rolled out Savvy’s Borescope Initiative in January. In the ensuing 7 1/2 months users have uploaded over 65,000 images to the repository. If you’re still waiting to participate, or if this is news to you, check out Savvy’s Borescope Initiative. Before the rollout, we suspected that most of the valves we looked at would show normal – symmetrical – heating patterns. We also suspected that we would catch some valves in various stages of burning that may not have been detected through compression checks or oscillations in EGT. We were right on both counts.

A borescope image report prepared by an analyst will classify exhaust valve head images Normal, Early/mid-stage uneven heat pattern, or Advanced uneven heat pattern. We hope the following examples assist you in deciding what intervention, if any, is appropriate.

If you are a SavvyMx client, your dedicated account manager can help you make this determination, and if you are a SavvyQA client, an account manager on our team will provide guidance.

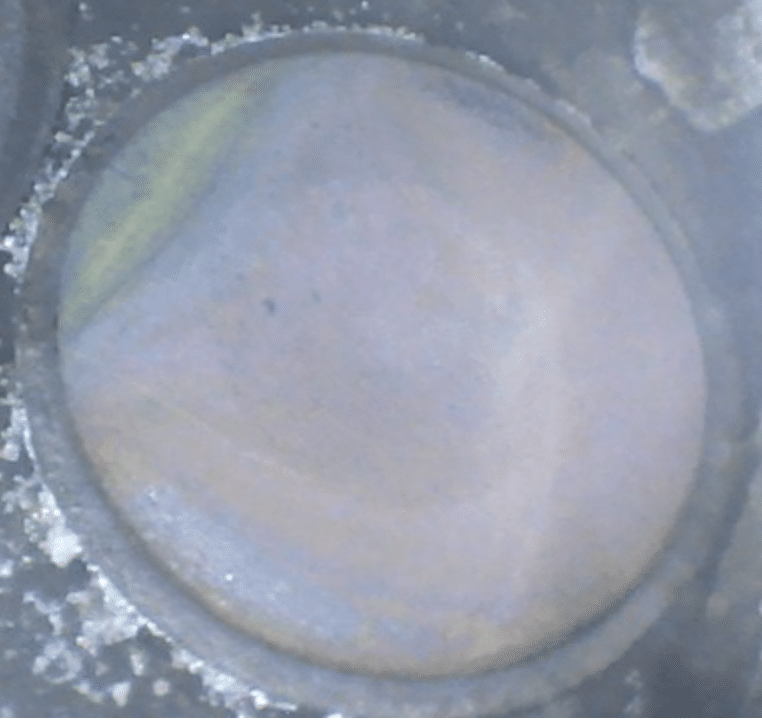

Normal heat pattern

A normal heat pattern in the exhaust valve head deposits will show symmetrical rings of varying color, or possibly uniform color over the entire valve head. The colors are not so important, although green usually will not occur in a normal valve. Here are examples of symmetrical heating.

Early-stage uneven heat pattern

In the early stage of a burn we sometimes see different patterns from Lycomings vs Continentals. Continentals tend to develop their burn patterns faster than Lycs. With Continentals, compression checks and listening for leaks helps cross-check what the scope shows.

With Lycomings, this early stage of valve failure is typically characterized by a small gap in the outer ring. Often we look at compression to tell if the heat pattern is acceptable or is a sign of an early stage of valve failure. Compression findings are especially helpful with Lycoming sodium filled valves. With Lycoming cylinders, if the compressions are the same on all cylinders, the valve might be fine and the valve should be inspected in 25 hours to monitor the trend. If the compression is in the low 60’s when the other cylinders on the same Lycoming engine are in the mid 70’s, lapping should be considered.

Mid-stage uneven heat pattern

The mid-stage of valve failure on a Continental engine is typically characterized by a gap in the outer ring and an oval shaped center. On a Lycoming engine we see a gap in the outer ring and the formation of a C-shaped heat pattern at the edge of the valve with the back of C at the outer edge of a bullseye. Valves in this stage are often safe to lap.

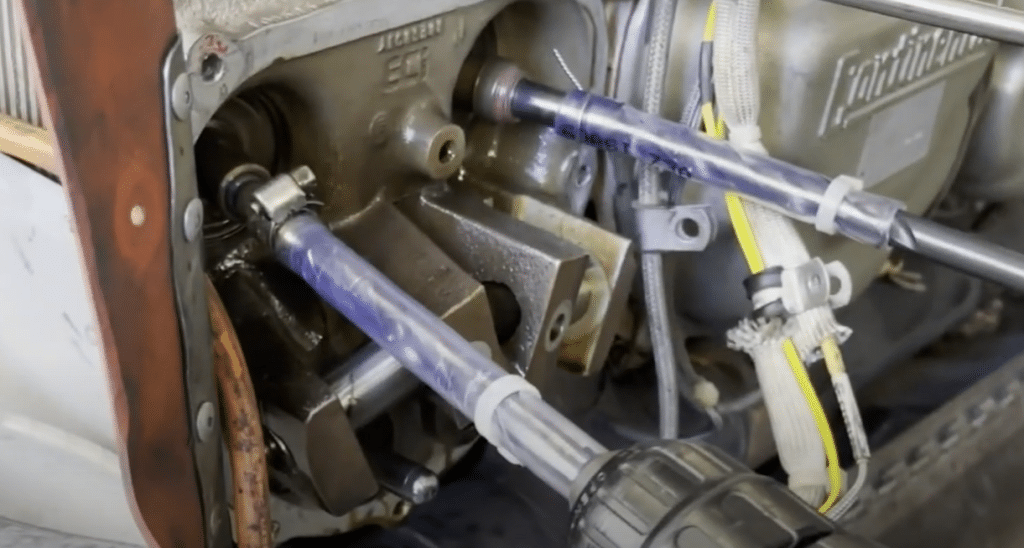

In the video linked here, Mike Busch demonstrates how to lap a valve in place.

Mike has written extensively on valve lapping. Click here to view some recent articles.

Late-stage uneven heat pattern

This is characterized by a bell-shaped heat pattern with or without green coloration in the center of the bell. Green coloration in the center of the bell typically means the valve is beyond being safe to lap, especially if the green area progresses into the valve from the edge. A cylinder that has been run beyond redline CHT often has 2 hot spots 180 degrees apart. It typically looks like 2 “Cs” with the backs of the “Cs” together in the center of the valve, often with green coloration at the edge of the valve in the location of the hot spots. Late-stage valve failure should be addressed by removing the cylinder and repairing or replacing it.

Success Stories

One of the features of the Savvy borescope repository is if there are previous images of that valve or barrel, they load automatically. Here’s a before and after screenshot of the same valve. The older pre-lapping image is on the bottom, the newer image is on top. The top image still has some coloration from the uneven heating, but the green tinge in the earlier picture is much improved. Of course we’ll want to monitor this valve as we would with any lapping candidate.

I did a quick informal survey of the Savvy maintenance managers to get a sense of their success with lapping valves. The consensus was a remarkable success rate with two caveats –

- some of the chats on the owner forums suggest that you can knock out a lapping job in an hour or less – be prepared to invest more time than that

- there may be an underlying issue that even a good lapping job won’t solve

Follow-Up

Another bit of advice we heard from several Savvy managers – think of a valve lapping as more of a process than an event. Monitor the valve’s progress with frequent borescope inspections.

Big thanks to all my Savvy colleagues – especially Chris Wrather and Dave Pasquale.