The term “damage history” is not well-defined. Here are some thoughts on the subject.

One of my clients just had a fancy digital engine monitor installed in his airplane. During the installation, the shop hired to do the work drilled a half-inch hole in a non-structural area of the cabin sidewall to accommodate the OAT probe, then realized that the hole was in the wrong place—the OAT probe wouldn’t fit due to interference—and and had to drill another hole in a more suitable location. The shop fessed up to its mistake, and assured my client that the first hole would be patched and painted so that it would be completely undetectable, and that this would be done at no cost to the client.

“Oh my god,” the client said to me in obvious panic, “does this mean that my airplane now has ‘damage history’? What will this do to its resale value?”

I get this a lot.

In the past two years, for example, there have been a half-dozen prop strikes among my managed maintenance clientele. All occurred either with the gear down-and-locked or down-and-welded, and in all cases but one there was no airframe damage whatsoever. A few of these prop strikes were of the “oops, forgot to remove the towbar” variety. One occurred when the pilot skidded on an icy runway and ran the prop into a snow bank. Another involved the gruesome decapitation of a runway light.

Most of these airplanes simply required a new propeller and a routine post-prop-strike engine teardown inspection, all fully covered by insurance. In every case, the owners expressed concern about whether the prop strike constituted “damage history” that would impair the resale value of the aircraft.

What is “damage history”

There appears to be no standard industry definition of “damage history.” Everyone seems to have their own idea of what the term means. Here’s a definition from the National Aircraft Appraiser’s Association:

“Damage history” refers to repairs to surfaces or systems after an accident or incident rendered the aircraft no longer airworthy (i.e., gear up landing, bird strike, severe hangar rash, etc.).

An appraiser friend of mine uses this definition:

“Damage history” means any history of an incident or accident that seriously affected the airworthiness or structural integrity of the airframe or engine(s), excluding control surfaces. Most “hangar rash” type repairs can be ignored, and are not considered as damage history. We also exclude leading edge skin repairs or windshield replacements for bird strikes.

I must tell you that I’m not especially fond of either of these definitions. The NAAA definition strikes me as way too broad—it classifies almost any repair as damage history. My appraiser friend’s definition seems arbitrary—why exclude control surface damage or leading edge skin repairs, but include prop strikes? (I’d be inclined to do exactly the opposite.)

Let me propose a couple of definitions of my own. Here’s one:

“Damage history” means a history of repair that materially impairs the fair market value of the aircraft.

Admittedly this isn’t a terribly useful definition, but I offer it to emphasize the fact that damage history is mostly in the eye of the beholder (prospective buyer). My appraiser friend is okay with leading edge skin repairs. I’m okay with prop strikes. One man’s meat is another man’s poison.

Let me take another stab:

“Damage history” means that the aircraft has suffered substantial damage whose repair is detectible through inspection (without referring to the aircraft’s maintenance records).

The essence of this definition is that it excludes (1) repairs of minor damage, and (2) repairs of major damage that are so complete as to be invisible.

For example, if the rudder sustains major structural damage in a windstorm, this would likely be classified as substantial damage. However, if the damaged rudder is replaced with a new one and none of the damage remains, it seems to me that the aircraft should not be tainted with damage history. If not one molecule of the damaged rudder remains on the aircraft, who cares that it was damaged?

What is “substantial damage”? It seems to me that the definition in NTSB Rule 830 is as good as any:

“Substantial Damage” means damage or failure which adversely affects the structural strength, performance, or flight characteristics of the aircraft, and which would normally require major repair or replacement of the affected component. Engine failure or damage limited to an engine if only one engine fails or is damaged, bent fairings or cowling, dented skin, small punctured holes in the skin or fabric, ground damage to rotor or propeller blades, and damage to landing gear, wheels, tires, flaps, engine accessories, brakes, or wingtips are not considered “substantial damage.”

Prop strikes

Conventional wisdom has it that a prop strike constitutes damage history. That makes absolutely no sense to me. When one of my clients reports a prop strike incident, I always counsel them to look at it not as a problem but as an opportunity. Why? Because invariably they will wind up with a better airplane than they had before the incident.

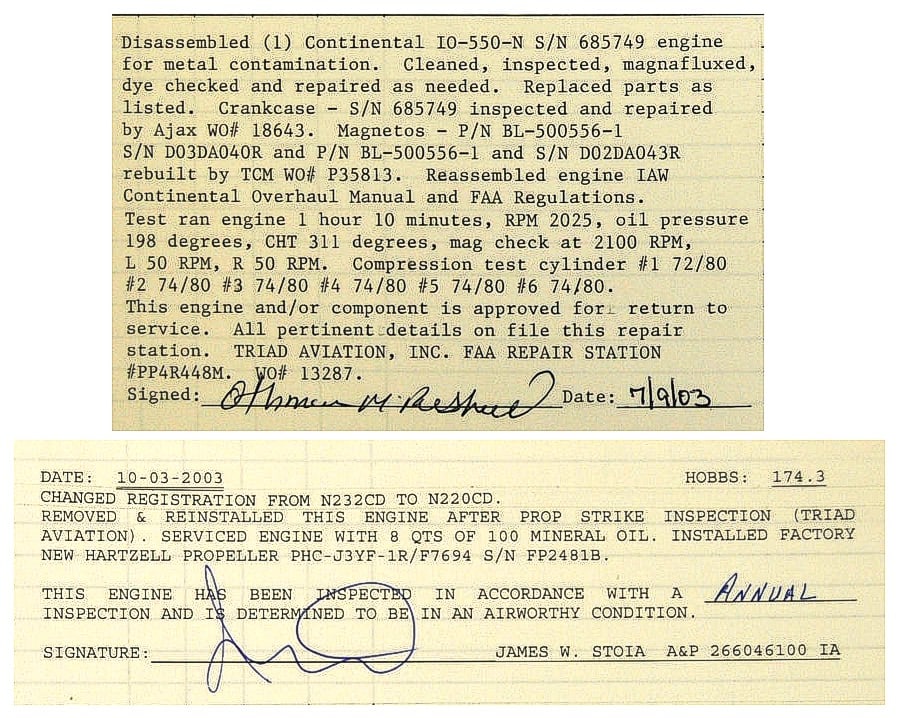

After a prop strike, the engine is typically sent to an engine shop for a teardown inspection. Both Lycoming and Continental have service bulletins that require this, and for Lycomings the service bulletin is mandated by Airworthiness Directive. The crankshaft, crankcase and various other components go through extensive non-destructive testing. The main bearings, rod bearings, thrust washers and other wear components are replaced with new ones. The magnetos, alternator, prop governor and other rotating accessories are undergo teardown inspections. The prop is often replaced with a new one, or at minimum the blades are replaced and the hub nondestructively tested. By the time the process is complete, both the engine and propeller are in better shape than they were before the incident. Furthermore, there is no physical evidence that any of this ever happened (other than paperwork).

The best part is that insurance pays for almost everything. What’s not to like?

My firm does a lot of pre-buys and represents a lot of prospective buyers. I cannot imagine discouraging a client from purchasing an aircraft because it suffered a prop strike, so long as the incident was properly dealt with in accordance with manufacturer’s guidance. For reasons stated above, if anything I consider a prop strike to be a plus, not a minus.

Logbook entries

Owners do need to be careful about what they allow mechanics to put in their aircraft maintenance logbooks. Be mindful that someday you may want to sell your airplane, and prospective buyers will be poring through those logbooks. You want your maintenance record entries to leave the best possible impression. They should be legible—preferably typed, not handwritten. They should be complete, thorough, accurate, well-organized and professional.

It’s amazing how often we see logbook entries that don’t meet this standard. That’s one reason that we never allow any shop or mechanic to write directly in our clients’ aircraft logbooks. We require them to make maintenance record entries on self-adhesive stickers, and we review them carefully before allowing them to be pasted in the logbooks. You’d be surprised how often we find erroneous or inappropriate logbook entries and send them back to the shop to be redone.

Recently, for example, I was reviewing the logbooks of an aircraft that a client was interested in buying. The logbook entry for the next-to-last annual inspection stated:

I certify that this aircraft has been inspected in accordance with the Mooney Aircraft Corp. Annual Inspection Checklist and is determined to be in an airworthy condition. /signed/ Izzy Inspector 135246789 IA

I found this to be a rather interesting and unusual entry, because the aircraft in question was a Cessna T210! Granted this logbook entry is now moot (since the airplane has gone through a subsequent annual inspection), but somehow that bogus entry didn’t inspire a lot of confidence in the shop that had been maintaining the aircraft. When reviewing aircraft logbooks for a possible purchase, perception matters.

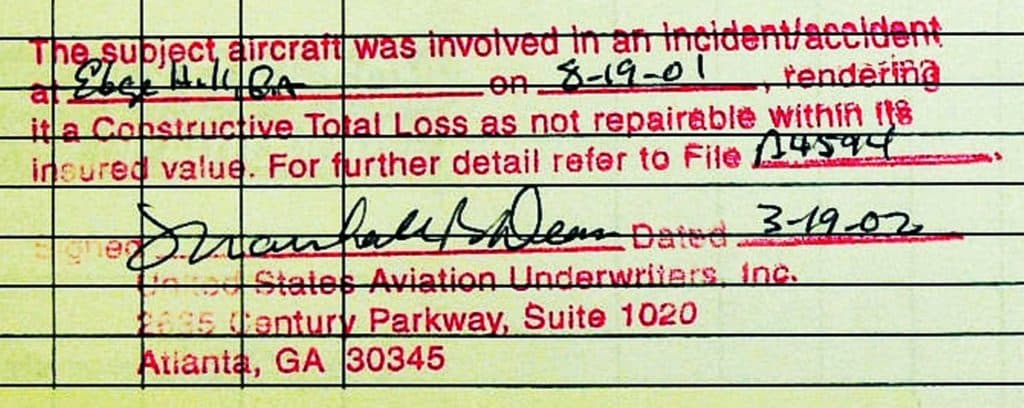

While reviewing the logbooks of another aircraft for a possible pre-buy, I discovered this rather remarkable entry:

I simply cannot fathom why an entry like this would appear in an aircraft maintenance records. The content of such records are governed by FARs 43.9, 43.11 and 91.417, and those regulations require that maintenance records contain “a description of the work performed.”

The entry in Figure 4 does not describe any work performed. It doesn’t relate to maintenance whatsoever. All it does is make the aircraft look bad. Such an entry is not required by any FAA regulation. It is gratuitous and totally inappropriate in my view.

My pre-buy client took one look at this entry and decided not to make an offer on the aircraft. Further logbook research indicated that the aircraft subsequently underwent structural repairs in accordance with a manufacturer’s Engineering Order performed by one of the top major structural repair shops in the country. It was probably an excellent aircraft that could have been purchased at a deep discount because of its damage history. (It certainly had damage history by anyone’s definition.)

Nevertheless, the “constructive total loss” entry was enough to spook my client and convince him not to consider buying the aircraft. When selling an aircraft, perception is reality.

You bought a plane to fly it, not stress over maintenance.

At Savvy Aviation, we believe you shouldn’t have to navigate the complexities of aircraft maintenance alone. And you definitely shouldn’t be surprised when your shop’s invoice arrives.

Savvy Aviation isn’t a maintenance shop – we empower you with the knowledge and expert consultation you need to be in control of your own maintenance events – so your shop takes directives (not gives them). Whatever your maintenance needs, Savvy has a perfect plan for you: