A few minutes after noon on Saturday, James Watson A&P/IA heard his smartphone beep to alert him to an incoming text message. The message read:

“N1357B is AOG at O59. Engine lost power. Had to make an emergency landing. Phillip 503-708-1212.”

James was the on-call account manager that day for the SavvyBreakdown 24/7 aircraft breakdown assistance hotline. Within two minutes, he was on the phone with Phillip to find out what happened.

Phillip told James that he had been cruising at Flight Level 200 in his turbonormalized 1973 Beechcraft V35B Bonanza on an IFR flight from Las Vegas, Nevada to his home base of Portland, Oregon. Just over three hours into the five-hour flight, suddenly and without warning the engine lost manifold pressure. Phillip declared an emergency to ATC and made a successful emergency descent and landing at the nearest airport, Cedarville, California (O59).

Cedarville has a field elevation of 4,623 feet MSL and a population of 606 people. It is located in Modoc County in the extreme northeastern corner of California, just south of Oregon and west of Nevada, a sparsely populated high-desert area.

James asked Phillip to describe the power-loss symptoms as well as he could remember them, then asked him if he could download the flight data from his JPI EDM 930 engine monitor to a USB flash drive and then upload it to the SavvyAnalysis platform so that James could take a look at it. Phillip said he could do that.

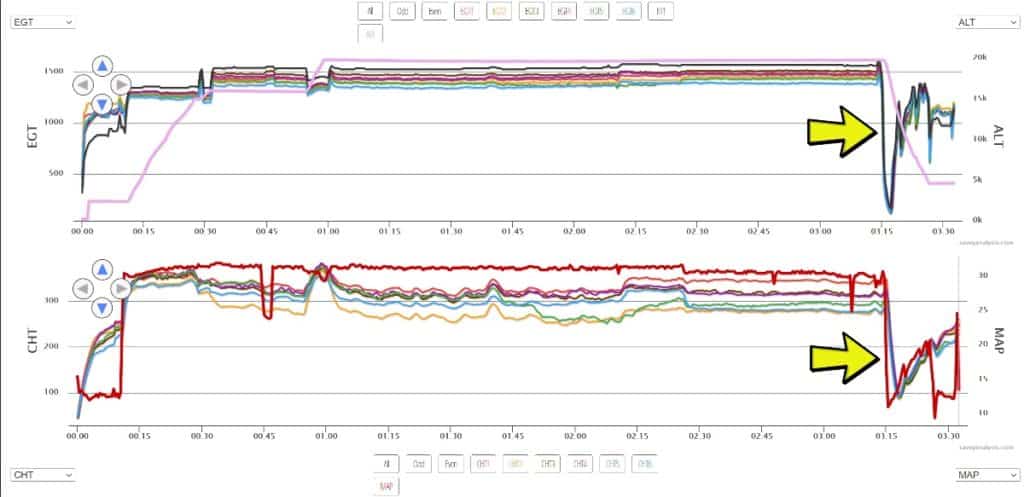

Not long afterwards, James was looking at a chart of the engine monitor data for Phillip’s ill-fated flight:

When James zoomed in on the last hour of the flight, he noticed that there were there were some manifold pressure anomalies starting 50 minutes prior to the final event:

Zooming in on that final event, Janes could see that manifold pressure suddenly dropped from 30 inches to 11 inches in a matter of seconds, and that it increased gradually up to 21 inches as Phillip descended from FL200 to airport elevation:

“Based on the symptoms you described and what I’m seeing in the engine monitor data, it looks like a complete failure of the turbosystem,” James told Phillip. “It appears that the engine suddenly went normally aspirated.”

James proceeded to list the various failure modes that could cause such a turbosystem failure:

- Failure of the turbocharger itself

- Wastegate stuck open

- Failure of the turbocontroller

- Massive induction or exhaust system leak

“Is there a shop or mechanic there I can work with to diagnose the problem,” James asked.

Phillip replied that the airport appears to have no services other than self-serve fuel, and looks almost abandoned.

“I do have some basic hand tools in the baggage compartment,” Phillip continued, “and do most of my own preventive maintenance.”

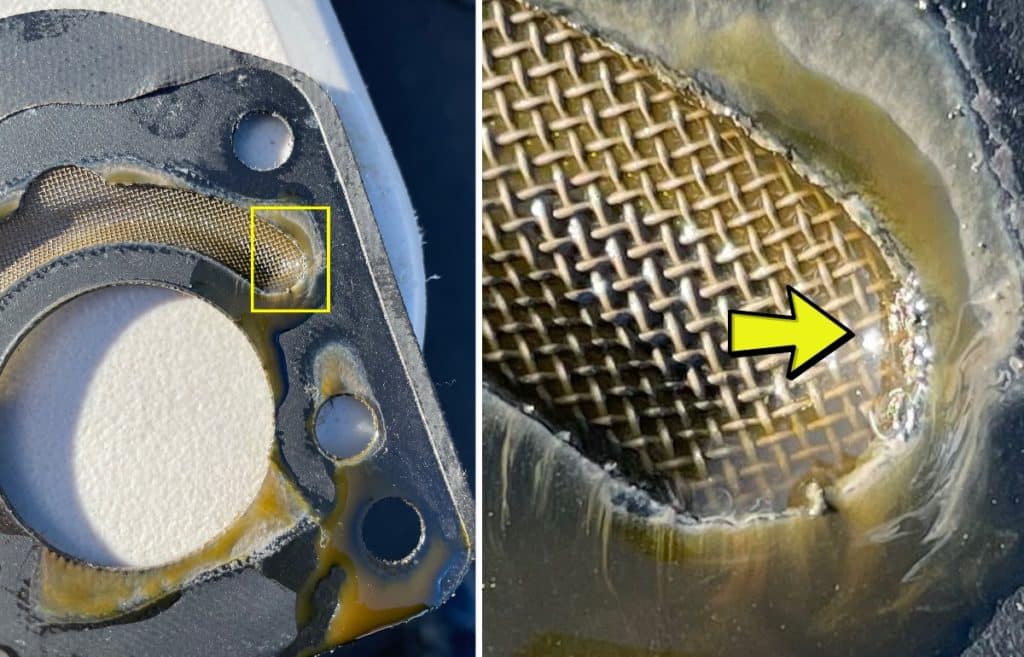

James encouraged Phillip to open the cowling doors, inspect the engine for anything that looks abnormal, and take smartphone photos of anything that looks interesting. Not long afterward, Phillip posted this photo:

At this point, James asked several other members of the Savvy team to weigh in.

“Clearly FOD was ingested by the turbocompressor,” said Savvy CEO Mike Busch A&P/IA. (FOD is an aviation term meaning “foreign object damage.”) “Possibly the engine ingested some fastener or other component of the induction system between the filter and the turbo.”

“I recommend borescoping all cylinders to see if the FOD that messed up the turbo was ingested into one or more of the cylinders,” Mike continued, “and if so how badly it damaged the piston, cylinder head, spark plugs and/or valves of said cylinder(s). Also, of course, the oil filter needs to be cut and the oil drained through a strainer to see if there are any big pieces of metal that couldn’t make it through the suction screen. If significant metal is found, then the prop governor should be removed and the prop governor gasket screen inspected for contamination. Once we have borescope, filter, strained oil and gasket screen results, we can offer Phillip a well-informed recommendation as to remedial action required prior to flight.”

Middle of Nowhere

“Problem is that O59 is in the middle of nowhere,” Mike continued, “and it’s not clear that there are any good maintenance resources closer than about 100 NM away. So if the aircraft is unflyable/unferryable, we may have a complicated issue on our hands. Closest shop we’re aware of is Jet Center MFR in Medford, Oregon about 100 nm to the northeast. Director of Maintenance there is Gary Hudnall, and it’s a great shop…but it’s a long distance away.”

“Yes, finding someone willing to travel to the aircraft in Cedarville could be problematic,” James agreed. “I have Phillip putting our feelers with Beechtalk and the American Bonanza Society group to see if anyone qualified is nearby, and I will reach out to Gary in Medford.”

A few hours later…

“I spoke to Gary at Jet Center MFR, and he is willing to help, thankfully!” James reported. “I told him we’d like to have the cylinders borescoped, oil filter cut, and oil drained through a strainer. He will also bring a replacement turbocharger in case it’s determined the aircraft would be safe to fly following turbo replacement. I gave Gary Phillip’s cellphone number so they can work out the logistics and financials. Gary has a Cessna 320 twin that he can fly to Cedarville with all the necessary tools and parts.”

The News Isn’t Always Good

“Gary traveled to the aircraft and determined that both the oil filter and governor gasket were contaminated with metal,” James reported a few days later.

“This changes the scenario pretty dramatically,” James said. “Gary is currently working up an estimate to pull the engine on site.”

Savvy’s technical director Jeff Iskierka A&P/IA jumped in at this point. “You may want to contact your insurance agent,” Jeff suggested to Phillip, “although in our experience engine failures are usually not covered. Also, a major maintenance event like engine removal and teardown is beyond the scope of SavvyBreakdown.” Jeff listed Phillip’s three options going forward:

- Work directly with Gary

- Upgrade to SavvyQA and keep working with Savvy in a consulting role

- Upgrade to SavvyMx and have Savvy manage the whole thing for you

James let Phillip know that in addition to his role as a Savvy account manager, he owns and operates an engine shop on the East Coast so he is intimately familiar with the process of engine removal, teardown, reassembly, and installation.

Phillip indicated that he would like to keep James in the loop and that he would upgrade to SavvyQA consulting. After thinking about it overnight, however, he changed his mind and opted for SavvyMx. He checked with his insurance agent, who confirmed that his hull insurance would not cover this event.

Overhaul Complication

Phillip also decided that he would bite the bullet and opt for a major overhaul or an exchange engine rather than just an IRAN. Quotes were obtained from a half-dozen engine shops. Most were in the $40,000 to $45,000 range, although one “boutique” shop quoted $53,000 to $70,000 depending on various overhaul options.

Almost all the shops quoted 10-12 weeks turnaround, and Phillip felt strongly that he could not afford to be grounded for that long. Another complication is that the engine in Phillip’s airplane was not a standard Continental engine, but had been modified per the Tornado Alley Turbo STC with a different fuel pump, starter adapter and scavenge pump to support the turbonormalizing system. Continental Motors and several of the overhaul shops said that installing these modifications on the new engine would void the warranty. Phillip found that unacceptable.

Finally, Phillip reached out to Bill Cunningham at Powermaster Engines in Tulsa, an excellent shop that is very highly thought of in the Beechcraft community. Bill indicated that he could overhaul Phillip’s engine to the Tornado Alley specifications and get it turned around in 6 to 8 weeks. Phillip felt the quote from Powermaster was a fair one, and decided to go that route. Bill said he’d ship an engine crate to Medford to facilitate trucking the engine to Tulsa.

Engine Removed, Airplane Secured

Meantime, Gary dispatched a couple of his technicians and truck to Cedarville.

“Just wanted to let you know the engine and propeller are here in Medford safe and sound,” Gary reported. “We were able to find a gentleman there who allowed us access to a hangar and said we could leave the aircraft there. We put Bounce sheets in the aircraft to repel any rodents, then covered and locked it.”

What happened to Phillip—a catastrophic mechanical problem in the middle of nowhere—is every aircraft owner’s worst nightmare. Fortunately, Phillip had enrolled his aircraft in the SavvyBreakdown program, enabling him to call Savvy’s 24/7 hotline and within minutes be in touch with Savvy’s team of veteran maintenance experts who helped diagnose the problem and come up with a solution.

Is your aircraft enrolled in this program? If not, shouldn’t it be?

You bought a plane to fly it, not stress over maintenance.

At Savvy Aviation, we believe you shouldn’t have to navigate the complexities of aircraft maintenance alone. And you definitely shouldn’t be surprised when your shop’s invoice arrives.

Savvy Aviation isn’t a maintenance shop – we empower you with the knowledge and expert consultation you need to be in control of your own maintenance events – so your shop takes directives (not gives them). Whatever your maintenance needs, Savvy has a perfect plan for you: