In a world of $7 avgas, it’s more important than ever to get the best bang for the buck.

How can we get the best fuel economy from our airplanes? Given the painful cost of avgas these days, this is a question on lots of airplane owner’s minds. That goes at least double for unfortunate folks like me and Mac McClellan who fly twins. So it’s a subject I’ve thought about—and researched—quite a bit.

It turns out that there are lots of pieces to this puzzle. There are all sorts of things we can do to optimize efficiency. Some are simple; some are a bit more complex. It does take considerable attention to detail to fly as efficiently as possible.

Throttle

Let’s start with something simple: throttle position.

Our piston aircraft engines are always most efficient at wide-open throttle (WOT). Retarding the throttle from its wide-open position closes the throttle butterfly valve in the carburetor or throttle body, and literally chokes off the engine’s air supply, intentionally reducing its volumetric efficiency. It doesn’t take rocket science to figure out that this is not something you want to do when striving for maximum engine efficiency. (Could you operate at maximum efficiency if someone was trying to strangle you? Neither can your engine.)

As a general rule, for best efficiency, we always want to be operating at WOT—or as close to WOT as we can without exceeding the engine’s operating limitations. Normally aspirated, turbonormalized and mildly boosted turbocharged engines can be (and should be) operated continuously at WOT.

Highly boosted turbocharged engines may need to be throttled back to remain with operating limits, but should not be throttled any more than absolutely necessary. Most of these engines are permitted to operate continuously at full red-line manifold pressure, but some are limited to five minutes. Check your POH.

RPM

If the airplane has a constant-speed prop, best engine efficiency and prop efficiency are generally achieved by setting the RPM as low as the book allows. Low RPM dramatically reduces frictional losses in the engine, which vary with the square of RPM. Low RPM also tends to increase propeller efficiency, because it increases the angle-of-attack of the propeller blades. And low RPM gives the engine more time to extract as much energy as possible from each combustion event before the exhaust valve opens and discards what’s left.

Operating at WOT and low RPM will make some pilots uncomfortable, because they had a flight instructor that taught them never to operate the engine “oversquare”—that is, with manifold pressure (in inches) greater than the RPM (divided by 100). This is exactly what I was taught by my primary instructor in 1965, and it took me more than a decade to figure out that my CFI didn’t know what the heck he was talking about. I guess I’m a slow learner.

This “oversquare is bad” concept is just one of those Old Wives Tales that refuses to die. It’s dead wrong. For optimum efficiency, we WANT to operate the engine as far “oversquare” as the book allows. Most normally-aspirated engines are approved to operate at least several inches “oversquare.” The turbocharged engines in my Cessna T310R operate all day long at 32 inches of MP and 2200 RPM (“10 inches oversquare”) and they’re both beyond 200% of TBO, so they obviously don’t mind a bit.

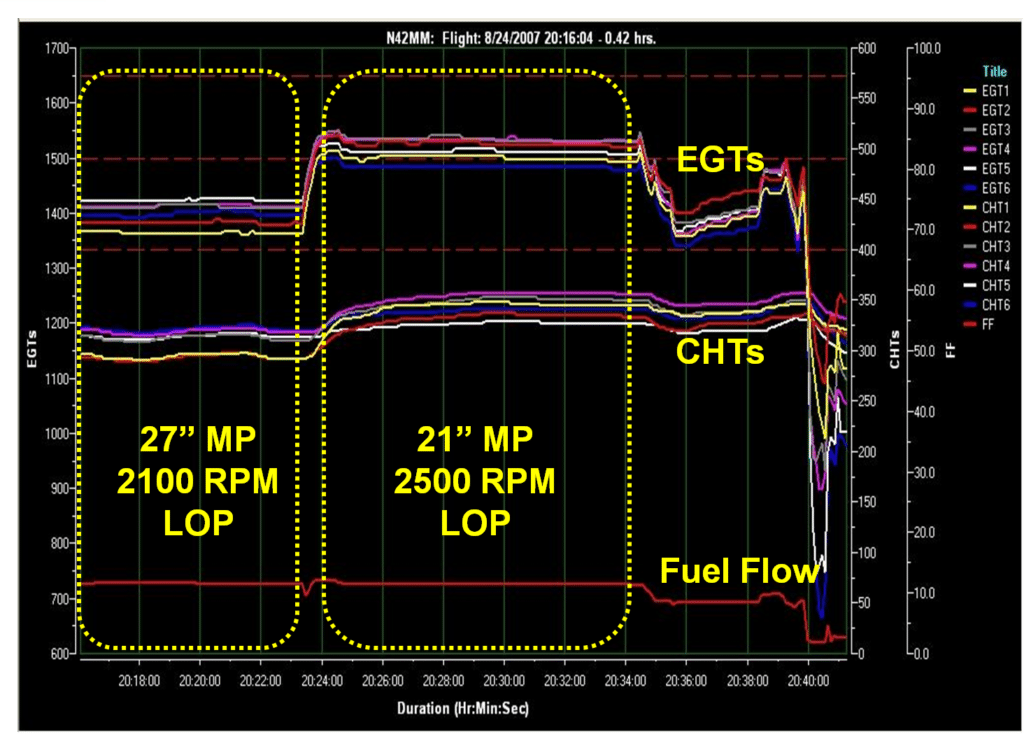

Have a look at an interesting test flight that my friend Elliott Schiffman made in his 1988 Beechcraft F33A a few years ago. (See Figure 1.) The first 8 minutes were flown at 27” MP and 2100 RPM (6 inches “oversquare” if you must), and the next 10 minutes were flown at 21” MP and 2500 RPM (4 inches “undersquare”). During both segments, fuel flow was precisely the same (about 12 GPH), which means that the exact same number of BTUs of latent avgas energy were being consumed. But during the second (“undersquare”) segment, the engine monitor data makes it obvious that much more of that latent energy was being wasted and substantially less was being converted into mechanical energy and airspeed.

The “undersquare” segment shows EGTs that are more than 100°F higher, reflecting the increased amount of energy being wasted out the exhaust. Why is this happening? Because at the higher RPM, there’s about 16% less time between when the spark plug fires and when the exhaust valve starts to open. As a result, the engine has less time to convert the heat and pressure of the combustion event into useful mechanical work before the exhaust valve opens and discards the remaining heat and pressure out the exhaust pipe.

The “undersquare” segment also shows CHTs that are about 50°F higher, mainly due to increased frictional losses in the cylinder assemblies. Those losses vary with the square of RPM, so should theoretically be roughly 65% greater at 2700 RPM than at 2100 RPM.

Naturally, if your airplane has a fixed-pitch prop, you can’t control RPM from the cockpit. The best you can do to obtain maximum efficiency is to have a “cruise prop” installed rather than a “climb prop.” The cruise prop has greater blade pitch and will operate at lower RPM than a climb prop, all other things being equal.

Mixture

Staying with the simple stuff: If we want to optimize efficiency, we need to lean aggressively. (Duh!)

So-called “best economy mixture”—which is the mixture that achieves minimum brake specific fuel consumption (BSFC) and maximum nautical miles per gallon of fuel—invariably occurs well on the lean side of peak EGT, typically somewhere between 30ºF and 70ºF LOP. To make things even simpler, if you lean the engine until the onset of perceptible roughness, then richen just enough to make the roughness go away (and not any richer), you’ll be close to best economy mixture. Pilots have been using this technique for about 100 years, and it works pretty well.

There are all sorts of other side benefits that come with operating the engine aggressively LOP. This method of operating is both cleaner and cooler. It reduces stresses on critical engine components, and it minimizes the buildup of harmful exhaust deposits. It’s the kindest thing you can do for your engine, and will provide you maximum longevity. (My own geriatric engines are a perfect case study of this.) Maximum longevity plus maximum efficiency—what’s not to like?

Airspeed

If you ask “what airspeed is most efficient,” things start to get a bit more complicated. That’s because there are a bunch of different airspeeds that compete for the title of “most efficient.”

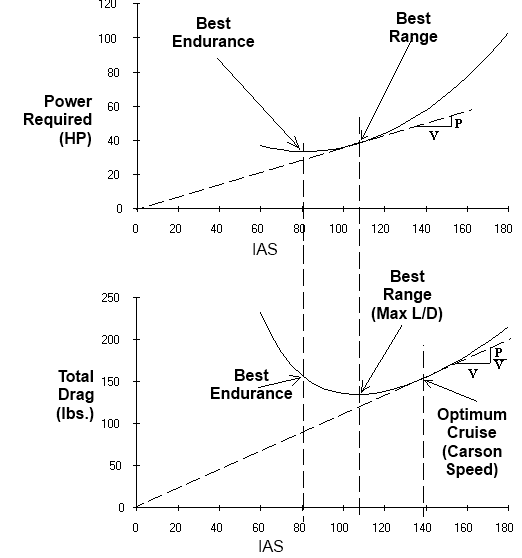

One such contender is the airspeed that achieves minimum drag. It is variously referred to as “maximum L/D speed” or “minimum thrust-required speed.” You can generally find it in the emergency procedures section of your POH as “best range glide speed.” For my Cessna 310, it’s 111 knots indicated. For an A36 Bonanza, it’s 110 knots indicated. Those speeds are at max gross weight; at lighter weights, the speed is a bit lower. (It varies with the square root of weight.)

When used as a cruise speed, this maximum L/D speed is the speed that provides best range. This is the speed you’d want to fly if you want to be able to fly as far as possible on a given amount of fuel, or alternatively if you want to get to your destination with the maximum amount of fuel reserve. This speed is sometimes useful when flying maximum-range missions, but it’s slower than most of us are willing to fly.

Two other contenders for the title of “most efficient speed” can be derived from this max L/D speed (a.k.a. best range speed). One is slower, the other is faster.

If we divide max L/D speed by 1.316, we get “best endurance speed” or “minimum power required speed.” This is the speed you’d want to fly if your goal was to remain aloft for the maximum time, or alternatively if you want to use the minimum amount of fuel per hour. This speed is useful for “loiter-mode” operations like aerial surveillance, fish spotting, pipeline patrol, etc. This is a very slow airspeed, and definitely will not satisfy your “need for speed.” It also puts maximum stress on your bladder.

A faster and more satisfying “most efficient speed” is obtained by multiplying max L/D speed by 1.316. This gives us what is commonly referred to as the “Carson speed” after renowned Naval Academy professor Bernard H. “Bud” Carson Ph.D., who wrote the seminal paper on this subject in 1980 and passed away in 2009. This speed attempts to optimize the two things we most care about: airspeed and fuel economy; it’s the speed at which the product of speed and fuel economy is maximized. For most of us, the Carson speed is probably as good a tradeoff between speed and economy as we’re likely to find.

Reducing this theory to some actual numbers: My Cessna 310 POH lists best range glide speed (max L/D) as 111 KIAS at max gross weight. (It decreases to 102 knots at 800 pounds under gross.) This means that my Carson speed would be 111 times 1.316, or about 146 KIAS. For a Cessna 210, max L/D is listed at 88 KIAS at max gross, so Carson speed would be about 116 KIAS.

Altitude

So far, we’ve determined that to achieve optimum efficiency, we want to cruise at wide-open throttle, minimum allowable RPM, and at an IAS of approximately Carson speed (which is relatively low as indicated airspeeds go). Let’s see if you’ve been paying attention. Here’s a snap quiz…

Question: How can we do all this stuff at the same time?

Answer: By flying at a relatively high altitude that allows us to fly WOT without exceeding Carson speed.

In a high-performance normally-aspirated airplane, this generally means cruising up around 12,000’ feet, give or take. In a turbocharged airplane, it usually requires climbing up to the low Flight Levels. These are the altitudes at which these airplanes are happiest and most efficient.

Random tips on efficiency

A GPS-coupled fuel totalizer, like the Shadin Digiflo I have in my Cessna 310, can be invaluable in achieving maximum efficiency. The instrument has a mode that continuously displays actual fuel efficiency (NM/gallon or NM/pound), and lets you try different power settings, airspeeds and altitudes, and see immediately what effect such changes have on fuel efficiency.

Like many pilots, I frequently use websites like AirNav.com and 100LL.com to check fuel prices along my route of flight. It’s amazing how wide the variation in fuel prices can be from one airport to another. It’s often tempting to land at an airport with exceptionally low fuel prices and fill all the tanks in order to avoid having to buy high-priced fuel at your planned destination. But succumbing to such temptation can be counterproductive.

For one thing, it almost never makes sense to make an extra fuel stop to load up on cheap fuel. That’s because the additional fuel it takes to make the descent, landing, takeoff and climb usually costs more than the cost savings from the lower-priced fuel.

For another, it’s important not to underestimate the reduced efficiency that occurs when we carry unnecessary weight, either fuel or payload. The weight-related performance penalty often offsets any savings involved in tankering cheap fuel. So while it’s painful to buy high-priced fuel, it often costs more to buy low-priced fuel if it involves an extra landing and/or tankering extra fuel weight.

You bought a plane to fly it, not stress over maintenance.

At Savvy Aviation, we believe you shouldn’t have to navigate the complexities of aircraft maintenance alone. And you definitely shouldn’t be surprised when your shop’s invoice arrives.

Savvy Aviation isn’t a maintenance shop – we empower you with the knowledge and expert consultation you need to be in control of your own maintenance events – so your shop takes directives (not gives them). Whatever your maintenance needs, Savvy has a perfect plan for you: