Wade had owned a variety of airplanes, including a couple of pressurized cabin-class twins. The plane he was now flying was a Cirrus SR22 Turbo, and he just loved it.

He found the plane’s 200-knot cruise performance at altitude quite remarkable. It was as fast as his old Cessna 340 despite having half as many engines and a down-and-welded landing gear, not to mention almost half the fuel burn. The wall-to-wall glass cockpit, outstanding visibility, and simple all-electric systems were frosting on the cake.

There was just one fly in the ointment. Wade was based in Wisconsin where it’s frigid in the winter and hot in the summer. The Cirrus did just fine in the winter, but in the summer he couldn’t keep the #3 CHT under 400°F no matter how hard he tried. The other five cylinders of his turbonormalized Continental IO-550-N seemed well behaved, but cylinder #3 was simply hot-headed.

Wade had been trying to solve this problem for two years. He’d asked his shop in Wisconsin to fix it. He’d taken it to a Cirrus Service Center in Minnesota. He’d even taken it to Tornado Alley Turbo in Ada, Oklahoma—the developer of the Cirrus turbonormalizing STC—for an annual inspection. Nobody could seem to solve the problem.

It wasn’t for lack of trying, either. These shops had checked the cooling baffles and baffle seals, checked the magneto timing, borescoped the cylinders, replaced the spark plugs, and cleaned tweaked the fuel nozzles. Nothing seemed to help. They’d even swapped the CHT probes around just to make sure it wasn’t an instrumentation issue. It wasn’t.

Conflicting Advice

Wade contacted Continental Motors in Mobile for help. The Continental tech rep said they never worry about CHT unless it regularly exceeds 420°F, and pointed out that CHT red-line is 460°F so Wade had nothing to be concerned about. Wade remained unconvinced. He was experienced enough to know that his #3 cylinder was unlikely to live long and prosper at such high CHT.

Not sure where else to turn, Wade enrolled his SR22TN in Savvy Aviation’s concierge managed maintenance program (SavvyMx). Savvy’s technical director Jeff Iskierka and founder/CEO Mike Busch got involved at this point. They reviewed the aircraft’s digital engine monitor data and studied its maintenance history to see what had been tried and what might have been missed.

Meantime, the various shops that had been working on Wade’s SR22TN were telling him that the only thing left to try was to replace the hot-running #3 cylinder. Wade was willing to try this, but Jeff and Mike suggested that he hold off.

For one thing, cylinder replacement is sufficiently invasive that Savvy recommends not doing it unless absolutely necessary. Wade’s #3 cylinder had good compression and looked just fine under the borescope. Removing it under these circumstances seemed like a desperation move.

For another, Jeff and Mike agreed that Wade’s high CHT problem simply did not “feel” like a cylinder defect. Both were convinced it was most likely caused by insufficient cooling air passing over the cylinder’s cooling fins, despite the fact that several different shops had looked at the cooling baffles and baffle seals and pronounced them healthy.

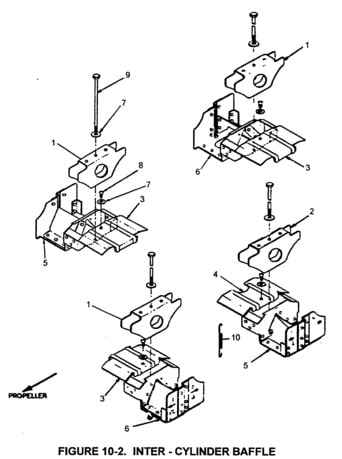

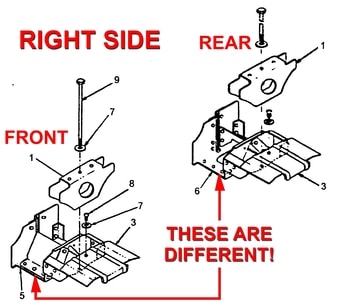

Given that only one cylinder was running hot, Jeff and Mike suspected a possible problem with the engine’s inter-cylinder baffles. These are small, odd-shaped pieces of aluminum that sit beneath and between adjacent pairs of cylinders and prevent cooling air from flowing through the gap between the cylinders and bypassing the cooling fins.

The Right Set of Eyes

In the meantime, Wade had relocated from Wisconsin to Wyoming, a place where Cirrus-qualified maintenance shops are few and far between. So when Wade reported having an issue with his Avidyne DFC-100 autopilot, Jeff recommended that he take the airplane to Arapahoe Aero at Centennial Airport (KAPA) just south of Denver. Arapahoe Aero is a Cirrus Authorized Service Center with a good avionics shop, and Savvy’s prior experience working with Arapahoe had been excellent.

Jeff contacted Arapahoe’s longtime Director of Maintenance, John Wells, and asked that he put Wade’s airplane on the avionics shop schedule for autopilot work. Jeff also told John that the airplane had been having a persistent problem with elevated #3 CHT and asked if John would inspect the engine to see if he could find anything that might be responsible for this, with special emphasis on the inter-cylinder baffles. John said he’d be happy to have a look.

Wade flew the plane to Centennial. The avionics shop worked on the autopilot while John and one of his most senior technicians inspected the plane’s engine. A few days later, John sent Jeff the following message:

We have been looking at the engine and I think we may have found the culprit. The inter-cylinder baffles on the right side of the engine are installed incorrectly. They are location-specific on the IO-550-N, and the baffles appear to be swapped front to back. This may seem like a minor thing, but we have seen it make a significant difference in the past.I would recommend swapping the baffles into their correct position and performing a test flight.

Subscribers to Savvy’s concierge maintenance management service (SavvyMx) are assigned a dedicated veteran A&P/IA account manager who is responsible for assisting with every aspect of their aircraft’s maintenance, often in collaboration with other members of Savvy’s technical team. Two of the most important things we do for our clients are to help them with shop selection and troubleshooting.

In Wade’s case, we helped keep the focus on the most probable diagnosis (inter-cylinder baffles, NOT a bad cylinder) and we steered him to a truly excellent shop where exceptionally experienced and knowledgeable mechanics were able to locate a problem that several other shops had missed.

Subscribing to SavvyMx cost Wade $750/year. Replacing the #3 cylinder would have cost him more than $3,000 and wouldn’t have resolved his CHT problem. We almost always save our clients more in reduced maintenance than what we charge them—often a LOT more. Wouldn’t you benefit by having Savvy manage the maintenance of your aircraft? Learn more about SavvyMx.

You bought a plane to fly it, not stress over maintenance.

At Savvy Aviation, we believe you shouldn’t have to navigate the complexities of aircraft maintenance alone. And you definitely shouldn’t be surprised when your shop’s invoice arrives.

Savvy Aviation isn’t a maintenance shop – we empower you with the knowledge and expert consultation you need to be in control of your own maintenance events – so your shop takes directives (not gives them). Whatever your maintenance needs, Savvy has a perfect plan for you: