I was talking with a friend recently and he said “I understand it intellectually, but I’m not sure I’ll ever grok it”. I haven’t heard that word in years, maybe as far back as reading Heinlein in high school. (I was more of an Asimov fan in those days.) But it got me thinking about whether I will ever grok engine data analysis — understand it profoundly and intuitively. In golf it’s a big deal when you shoot your age. I’m 68 and this is my 68th Puzzler. I’d like to think by now I understand it intellectually and I’ll probably never grok it, but I’m happy that these articles have found an audience and new issues continue to emerge.

Extemporaneous speaking is hard. In February I was interviewed by Brandon Gonzales for his Podcasting on a Plane series. I started an IMC Club at my local airport and Brandon is a tower controller there and an advisor to the club. Last month I was interviewed by Dean Showalter for his Airplane Owner Maintenance podcast. I taught at the college level online and in the classroom on and off for 20 years. I’ve created over a dozen training titles. So I’m pretty comfortable when I’ve got a script and I know what’s coming next. Answering questions is a lot harder. So I have a new appreciation for people that can do that.

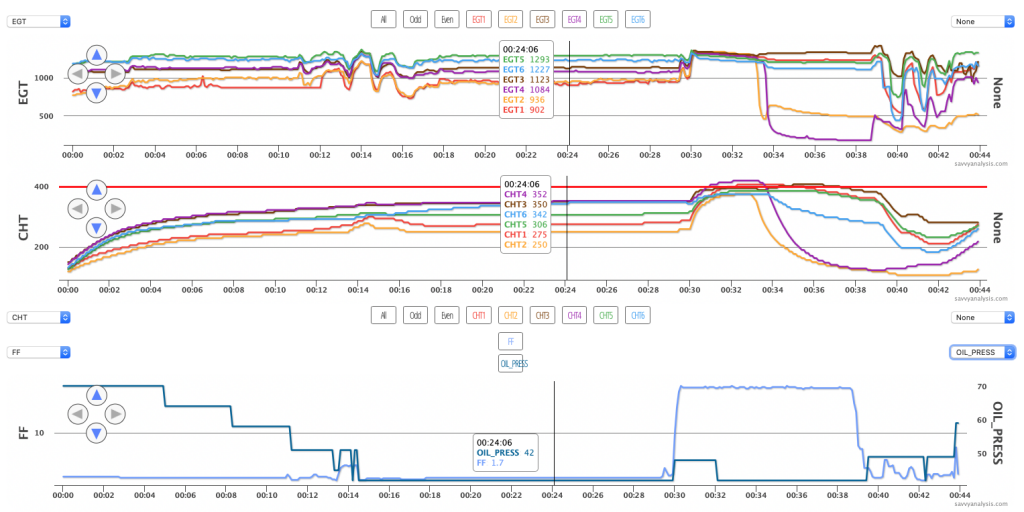

On Dean’s podcast we talked about data from an airplane he was working on. Let’s start this month with data from that Cessna 172XP with a Continental IO-360 engine and data from a JPI 830 with a 6 sec sample rate. EGTs on top, CHTs below, then FF and oil pressure together. I moved the cursor away from the event so it didn’t block the traces, but you can see that the oil pressure is about the same at idle and after the event at the 33 min mark.

When Dean initially sent the data to me, he told me that a rocker boss had failed on one of the valves. He didn’t tell me whether it was the intake valve or the exhaust valve. He didn’t tell me which cylinder, either. One of the hazards in this job – but certainly not unique to this job – is to develop a theory and then look for all the evidence that supports it, and in the process overlook data that might support a different theory – confirmation bias. EGT and CHT data show that normal combustion has stopped for cylinders 2 and 4. My first theory was that the intake valve for cyl 4 had failed, the valve was stuck open and causing an induction leak that spilled over into cyl 2. I didn’t have an explanation for why cyl 6, which is the same distance from cyl 4, was not equally effected. And I didn’t have an explanation for why oil pressure didn’t change.

But then I noticed that EGT and CHT 4 rise in the last 4 mins of the data, but EGT and CHT 2 stay low. As I was falling out of love with my intake valve of cyl 4 theory, Dean offered that the failure was on the exhaust valve of cyl 2, and did I have a theory that would explain this data? If you listen to the podcast you can hear us carve this out in real time. When the boss fails and the rocker arm of the valve no longer has the leverage to open the exhaust valve, the springs hold it shut. Combustion is still taking place and the engine is at full power – the event is only 3 mins after takeoff power is applied.

So where is the exhaust from cyl 2 going? It should be going out past the exhaust valve into the port and out the riser, but it can’t get out of the cylinder, except maybe some blow-by past the piston rings. The theory is it’s backing up into the intake system whenever the intake valve opens, ruining combustion for cyl 2 and impacting combustion for cyl 4. Cyl 6 is too far down the line to suffer the same effect. If you have a different explanation please leave a comment.

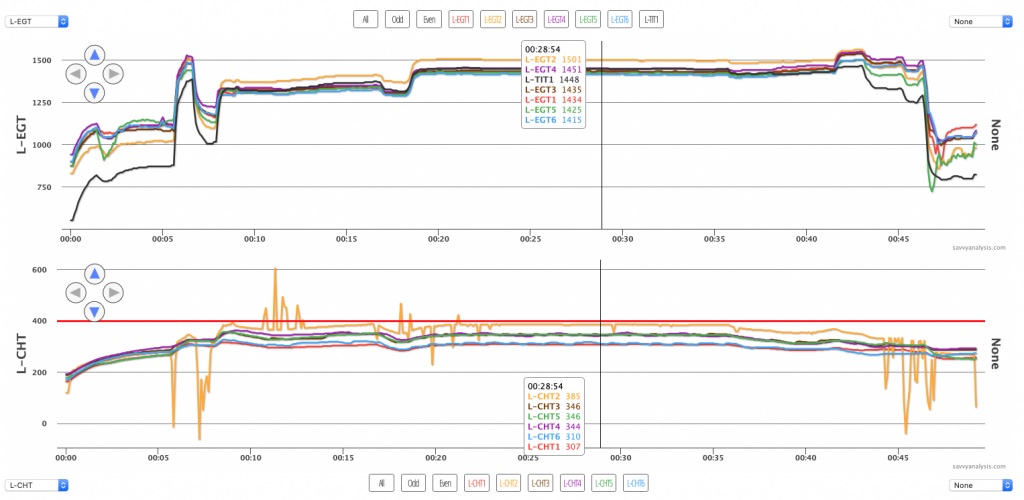

Next up is left engine data from a Piper Turbo Seneca III with Continental TSIO-360 engines and data from a JPI 760 Twin. EGTs with CHTs below.

Again it’s cyl 2 making the trouble. If we ignore EGT 2 for the moment, the erratic jumps in CHT 2 look like a loose connection. We know it’s not real changes in CHT because the thermal mass of a cylinder can’t change that fast. We can’t rule out a failing probe but typically they’ll track high or low – depending on the brand of probe – and stay there. Jumps like this are usually because of a poor connection. Notice that the spikes point down at takeoff and approach, point up in climb and go both ways in cruise before settling down, and we can’t just ignore that EGT 2 is tracking those changes – low at low power and high at high power.

Could we have a loose connection AND a failing probe? Because the highest CHT spike goes to 600º and the lowest spikes dip below 0º. That can’t happen. If we had an exhaust leak, we’d expect lower EGT because the hot gas has an alternate escape route and the leak might allow some cooler ambient air into the exhaust riser. But what accounts for the change in spike direction in different phases of flight? There does seem to be a vibration factor at work. Our recommendation was to start by checking the connections for the probes and in the course of doing that they found this. Not all leaks are the same and this one was a doozy.

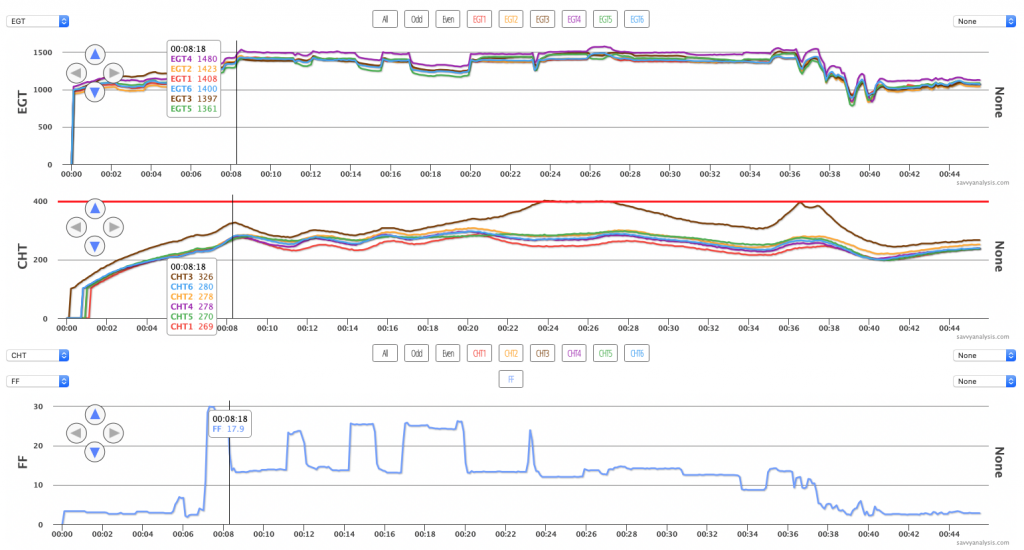

We’ll finish this month with data from an SR22 with a Continental IO-550 engine and data from an Avidyne with a 6 sec sample rate. EGTs, then CHTs and FF.

The things that stand out to me are EGT 4 is high throughout – but CHT 4 is normal – and CHT 3 is dangerously high at times – but EGT 3 is normal. Honorable mention to CHT 1 for being slightly low but not really a mirror image of CHT 3. It’s suspicious that the first data for CHT 3 at 00:00 in the timeline is logging ahead of the others and rises parallel to the others during taxi-out and takeoff. (Cursor is at the big mixture pull.) But then it sort of joins the others for a while before beginning its big excursion.

What do you think? Connection? The trace is steady. Combustion? EGT 3 doesn’t corroborate. Failing probe? Maybe, but why is it ok during initial cruise to the right of the cursor before acting up again? Could an exhaust leak be torching the CHT 3 probe and could that account for the change during various angles of attack? Our recommendation was to check for that and that’s exactly what it was. The orange arrow shows evidence of a small leak from cylinder #1 next door, and the exhaust leak appears to be enough to reduce the power output of cyl 1 which accounts for why CHT 1 was a little low.