Doug and Andy lavished their 1969 Cessna 182M Skylane with both love and money. Two years ago they’d treated her to a zero-time Continental O-470-R. To make sure they were treating the new engine properly, they’d upgraded their engine monitor to a spiffy new Electronics International CGR-30P. The engine had been sweet when they last flew it on the day before Christmas. But now it was the day after Christmas and the engine was very sick.

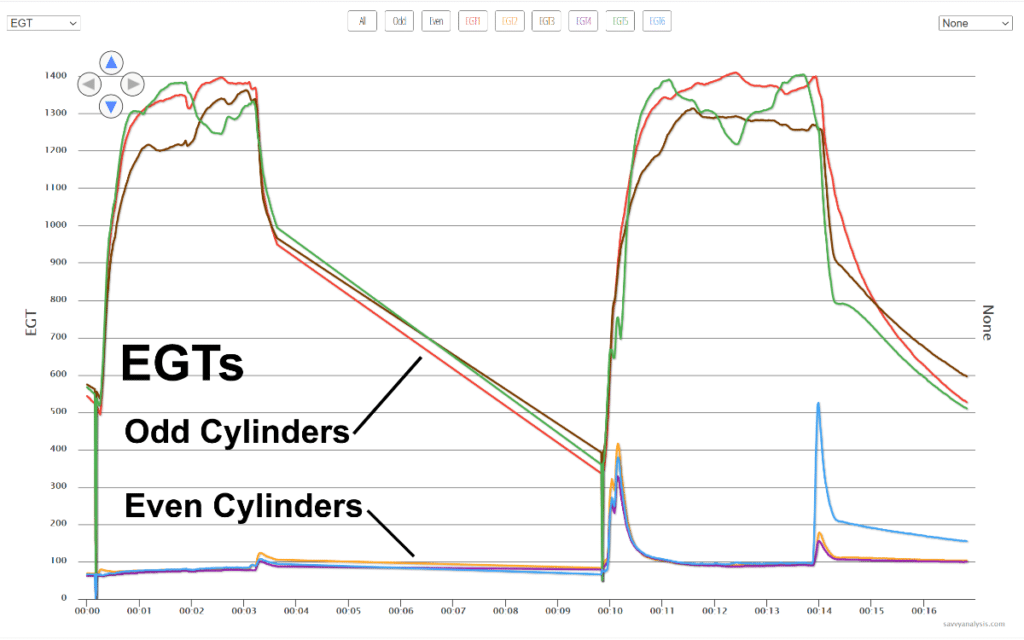

“We tried to start the engine this morning,” Doug posted. “It was cool at the airport—about 40°F—so we pumped the throttle twice to prime the engine. The engine was reluctant to start, and when it finally did it was really rough and the engine monitor seemed to indicate that only three cylinders were firing and the other three were cold. We pulled the mixture to idle cutoff, dumped the engine data, and uploaded it to the Savvy platform. If you look at it, you’ll see the problem…”

“If you look back at the previous flight history,” Doug continued, “you’ll see the plane was starting easily and flying perfectly over the past several days, including the day before Christmas…”

Doug’s ticket was assigned to Ray Eaker, one of Savvy’s professional engine data analysis specialists. Ray is both a private pilot and an A&P mechanic with over 30 years of aviation maintenance experience. He swung wrenches on Blackhawk helicopters in an Army special operations unit at Hunter Army Airfield, and now owns and operates Volo Aero LLC in Savannah, Georgia providing maintenance and avionics services to general aviation and experimental aircraft. Ray owned and flew a Cherokee 140 which he sold in order to finish his experimental RV-7A in 2017.

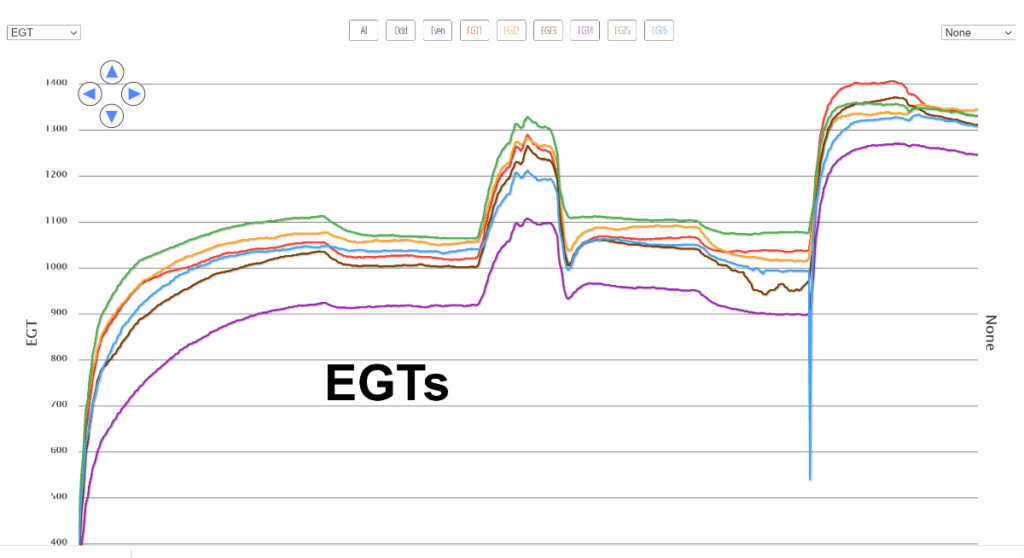

“Only odd number cylinders were firing,” Ray told Doug after reviewing the engine data. “This almost has to be a large induction leak. If you look carefully at the 00:14:00 mark in the data, you’ll see that the #6 (even-numbered) cylinder started to light after fuel flow went up temporarily, but went cold again as soon as the fuel flow was reduced. This suggests a too-lean-to-burn mixture for the even-numbered cylinders. Check for a loose or damaged induction coupling on the lefthand branch of the intake manifold.”

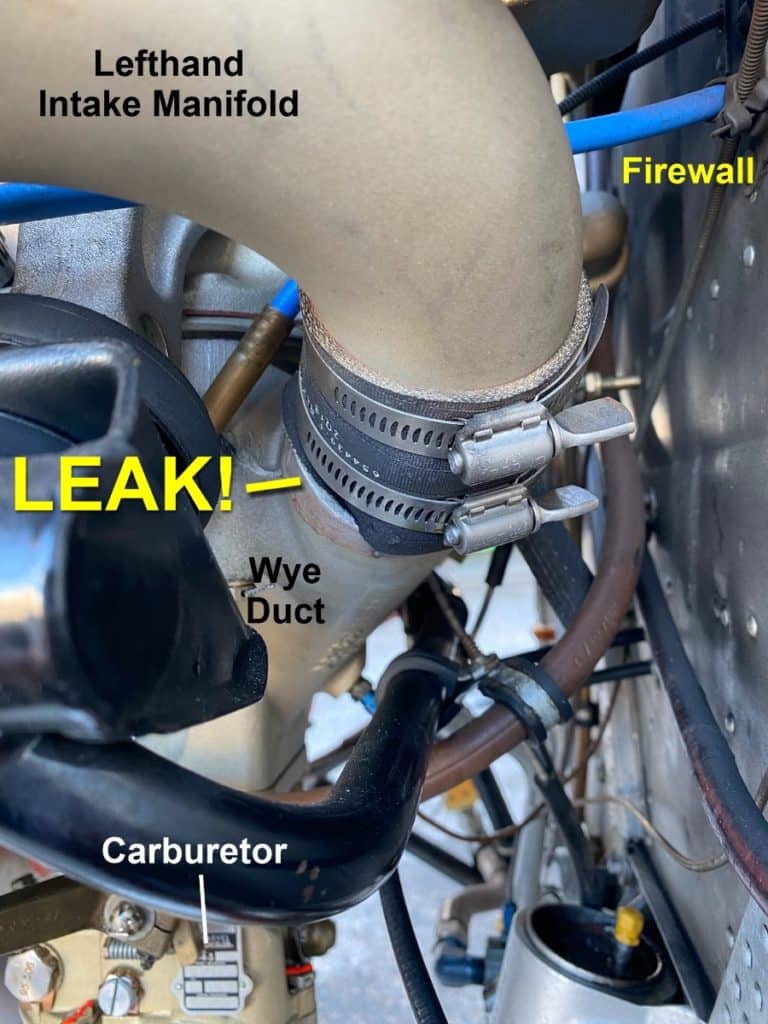

“Wow, Ray, you sure nailed that diagnosis,” Doug reported the next day. “Look at what we found…”

The photo clearly indicated that the induction coupling connecting the wye duct above the carburetor to the intake manifold feeding the lefthand bank of cylinders had not been properly clamped and had slipped off the wye, allowing the even-numbered cylinders to breathe ambient air from inside the engine compartment rather than fuel-air mixture from the carburetor.

“Great catch,” Ray posted. “Thanks for the photo.”

Sliding the induction coupling back into place and securing it with the two stainless steel hose clamps resolved the problem completely, and Doug and Andy were back in the air.

“Thanks so much, Ray,” said Doug. “Andy and I learned a lot from this! We didn’t really understand how the induction system works. Now we do. Savvy is invaluable!”

Doug’s day-after-Christmas predicament is a good illustration of the remarkable diagnostic power of engine monitor data when looked at by a trained set of eyes. What Ray did for Doug isn’t unusual. Here is verbatim feedback from a few other SavvyAnalysis Pro clients:

“You were exactly right. There was a tear in the baffle right above the #5 cylinder! Will get it fixed right away. This service is SO worth the price!”

“Using SavvyAnalysis Pro has enabled me to learn how to fly my aircraft better and manage my engine scientifically.”

“Great advice. You were spot on! Doing an in-flight LOP mag check at 8,000’ per your flight test profile revealed that the bottom #3 spark plug was dead as a doornail in these conditions. This never showed up on my preflight runups. Thank you Thank you for your help.”

“Very clever diagnosis. You guys rock!! Do you have Savvy stickers I can put on the plane? Everyone should be using your service!”

At just $129/year for a piston single—probably less than what you’d pay for the proverbial “$100 hamburger” nowadays—you can have world-class experts like Ray on your team, helping you pinpoint engine problems and improve your powerplant management skills. Learn more about SavvyAnalysis.

You bought a plane to fly it, not stress over maintenance.

At Savvy Aviation, we believe you shouldn’t have to navigate the complexities of aircraft maintenance alone. And you definitely shouldn’t be surprised when your shop’s invoice arrives.

Savvy Aviation isn’t a maintenance shop – we empower you with the knowledge and expert consultation you need to be in control of your own maintenance events – so your shop takes directives (not gives them). Whatever your maintenance needs, Savvy has a perfect plan for you: