If you ask FAA lawyers what a regulation means, the answer might surprise you

We’ve all studied the regs. If you’re a pilot, you’ve spent hours poring over Part 61 (pilot certification, ratings, currency) and Part 91 (operating rulese, owner responsibilities), both of which are voluminous. If you’re a mechanic, you’ve hopefully memorized Part 65 (mechanic eligibility, privileges and limitation) and Part 43 (maintenance) which are comparatively shorter but quite pithy.

These regulations are written and maintained by a large team of FAA lawyers who work for the Regulations Division of the FAA Office of the Chief Counsel. If you have a question about the meaning of a rule, you can write to the Assistant Chief Counsel for Regulations (AGC-200) requesting a legal interpretation. (It’s sort of like asking the IRS for a revenue ruling.)

Your request will be assigned to one of the rulemaking attorneys responsible for that particular section of the FARs, who hopefully will prepare a detailed written legal interpretation to be signed by the Assistant Chief Counsel and sent to you. Hopefully you’re not in a hurry, because the wheels of government turn slowly. Response time is generally at least several months, sometimes a lot longer.

More than 1,000 of these legal interpretations can be found in the Chief Counsel’s online database, searchable by keyword; Google “FAA legal interpretations.” Some are quite surprising and counterintuitive. Some significantly alter what most of us thought the regulations mean. I’ve requested a few myself (search keyword “Busch” if you’re curious), and I keep a folder of the most interesting and significant legal interpretations that affect maintenance. Here are some of my favorites…

Preventive Maintenance

Topping my list is the February 2009 Coleal interpretation that drastically redefines what “preventive maintenance” a pilot-rated aircraft owner is allowed to perform without A&P involvement. Part 43 Appendix A contains a list of 31 specific tasks that the FAA permits owners to do, and the introduction to that list states that “preventive maintenance is limited to the following work…”

Advisory Circular AZc 43-12A (“Preventive Maintenance”) goes even further, stating “if a function does not appear in this list, it is not preventive maintenance.” So, any work that isn’t on that list of 31 tasks requires A&P involvement, right?

“Wrong!” said the FAA lawyers in February 2009 in a legal interpretation requested by David Coleal, VP and GM of Bombardier Learjet. Coleal’s specific question to the FAA lawyers was whether a pilot could legally check the tire pressure on a Learjet 60 or whether a mechanic was required to do it. Checking tire pressure is not on the list of 31 items, but the FAA lawyers stated that it was something the FAA would consider to be preventive maintenance that a pilot could legally do.

But the lawyers went much further than that, stating that “the list [is] better viewed as examples of the tasks in [that] category—they cannot be considered all-inclusive.” The interpretation went on to say “There are, no doubt, many ‘simple [tasks] performed daily, especially onsmall general aviation aircraft, that the agency would consider to be preventive maintenance, though they are not included in the … listed items.”

The Coleal interpretation opens the door for aircraft owners to perform more maintenance on their aircraft on their own recognizance. If the work is not on the FAA’s list of 31 tasks but is comparable in terms of complexity and risk to the listed items, then the FAA would probably not take issue with it being treated as preventive maintenance that an owner is permitted to do.

In view of the current acute mechanic shortage, this is a wonderful thing in my view.

Current Manuals and Revisions

The word “current” appears in a number of regulations. For example, 91.409(f) permits operators of multiengine turbine airplanes to adopt the “current inspection program recommended by the manufacturer.” Further, 43.13(a) requires “Each person performing maintenance … shall use the methods, techniques, and practices prescribed in the current manufacturer’s maintenance manual or Instructions for Continued Airworthiness prepared by its manufacturer…” Does this mean that we always follow the latest version of manufacturer’s guidance?

No, it doesn’t. A February 2009 request from the Sacramento (Calif.) FSDO resulted in an August 2010 interpretation (it took 17 months if you’re counting) that clarified the meaning of “current” in a fashion that seemed rather surprising. In the case of those multiengine turbines, the “current” inspection program recommended by the manufacturer means the one that was current when the operator adopted it, not the one that is current now.

The interpretation of what methods, techniques and practices must be followed per 43.13(a) is even more interesting. Although the word “current” with respect to the manufacturer’s maintenance manual and ICAs has the normal meaning—current as of now—that does NOT mean that maintainers are required to follow the latest versions of those documents. That’s because 43.13(a) also allows the use of “other methods, techniques, and practices acceptable to the Administrator.” So, if you prefer to maintain your 1947 Beechcraft Bonanza in accordance with the version of the maintenance manual that was current when your airplane rolled off the assembly line, that’s fine. That old dog-eared manual was “acceptable to the Administrator” in 1947, and unless something has caused the FAA to change its mind since then (highly unlikely), it’s still acceptable.

The important legal principle here is that manufacturers are not permitted to change the rules that owners must play by in the middle of the game. Only the FAA is allowed to do that, and only by issuing an AD or some other rulemaking action.

A particularly egregious case occurred in February 2014, when Cessna Aircraft published a revision to the Cessna 210 service manual that added a new Airworthiness Limitations Section (ALS) to the manual that mandated eddy-current inspection of the wing main spar lower caps. These costly inspections were required starting at 8,000 hours for most 210s, and then every 2,000 hours thereafter. For 210s operated in a “severe environment” the new ALS required the inspections at 3,500 hours and every 500 hours thereafter. Cessna somehow convinced the FAA’s Wichita Aircraft Certification Office (ACO) to sign off on this, seemingly giving it the force of law.

With my encouragement and assistance, my colleague Paul New, owner of Tennessee Aircraft Services (a Cessna Service Center specializing in 210s) challenged this by requesting a legal interpretation from AGC-200 asking whether compliance with this very burdensome ALS published in 2014 was actually required, given that Cessna ceased production of the Cessna 210 in 1986. It seemed to Paul and me that this ALS was a pretty blatant attempt by Cessna to change the rules in the middle of the game.

In a five-page legal interpretation issued in May 2015, the FAA lawyers agreed. They opined that such an “after-added” ALS would not be retroactively effective against aircraft manufactured prior to its publication date. This effectively rendered the new ALS null and void. The legal interpretation concluded by saying that in February 2015, the FAA’s Small Airplane Directorate asked Cessna to revise the Cessna 210 service manual to clarify that the wing spar eddy-current inspections are encouraged but optional unless later mandated by an Airworthiness Directive. (Such an AD was ultimately issued five years later in 2020 and revised in 2023.)

SLSA’s and TBO’s

Special Light Sport Aircraft (SLSAs) are regulatory oddballs. They’re not FAA-certified—they don’t have a Type Certificate—and they’re not experimentals, either. They’re factory-built aircraft that conform to “consensus standards” created by Committee F37 of ASTM International, a non-profit standards organization headquartered in in West Conshohocken, Pennsylvania. Although these consensus standards have been accepted by the FAA, they are not FAA-approved. They don’t fit into the FAA’s regulations regarding airworthiness, certification or maintenance, which has made them a regulatory hot potato that the FAA rulemaking folks have been reluctant to touch.

Under pressure from EAA, the FAA adopted the Light Sport Aircraft rule 91.237 in July 2004. With respect to maintenance requirements, the FAA basically opts out. The rule requires SLSAs to be maintained in accordance with manufacturer instructions, to comply with all manufacturer-issued “safety directives” (like ADs except that they don’t come from the FAA), and not to be altered except as approved by the manufacturer. This gives the manufacturers of SLSAs absolute control over maintenance requirements, including unfettered ability to change the rules in the middle of the game. This puts SLSA owners at the manufacturer’s mercy in a fashion that owners of certified airplanes aren’t.

The vast majority of SLSAs are powered by Rotax 900-series engines. Rotax specifies a calendar-time TBO of 12 years for these engines. So, as the 12-year anniversary of the SLSA rule approached, many SLSA owners started asking “do I really have to overhaul my engine?” A couple of them posed this question to AGC-200 and requested a legal interpretation.

Then something odd happened. In August 2013, AGC-200 issued a legal interpretation (“Willette”) stating: “The intervals specified in maintenance manuals for S-LSA, therefore, are not per se mandatory. Consequently, a maintenance provider may develop an alternative that is acceptable to the FAA…” Then two years later, in July 2015, AGC-200 issued another legal interpretation (“Keller”) stating: “The aircraft would not be airworthy if operated beyond TBO…” Two legal interpretations written by two different FAA attorneys two years apart arriving at diametrically opposite answers!

In May 2016, I sent a lengthy letter to AGC-200 pointing out this embarrassing contradiction. “Clearly Willette and Keller cannot both be correct,” I wrote. “I am requesting a definitive interpretation of which of these two interpretations the owner or operator of an SLSA may rely upon.” I went on to argue passionately that TBO compliance should not be compulsory. “It certainly would feel wrong if operators of SLSAs were held to a more burdensome standard with respect to TBO compliance than operators of larger, more complex Part 23 certificated aircraft,” I wrote.

More than a year later, I spoke with the rulemaking attorney to whom my request had been assigned. (Apparently, he drew the short straw.) He apologetically told me that the interpretation I requested would not be forthcoming. “The folks in the Maintenance Division don’t want to touch this,” he said.

The issue remains unresolved. If you’re an SLSA owner, you have two contradictory legal interpretations. Take your pick. (Wink.)

A&P Experience Requirement

The FAA doesn’t make it easy to qualify as an A&P. To become eligible to take the three mechanic knowledge tests (general, airframe, powerplant) and the practical test (an all-day affair conducted by a Designated Mechanic Examiner), you must first meet the experience requirements which are rather daunting. FAR 65.77 defines two alternative ways to meet them. One is to graduate from a Part 147 certified aviation maintenance technician school; the other is to document 30 months of full-time experience (or equivalently 4,800 hours of part-time experience) swinging wrenches on civil aircraft.

I earned my A&P via door #2, and it took me 10 years of part-time work on my own airplane and a few others (mostly under A&P supervision) to reach the 4,800-hour requirement. To put this in perspective, it takes 1,200 hours of experience to qualify for the ATP, but four times as many hours to qualify for the A&P.

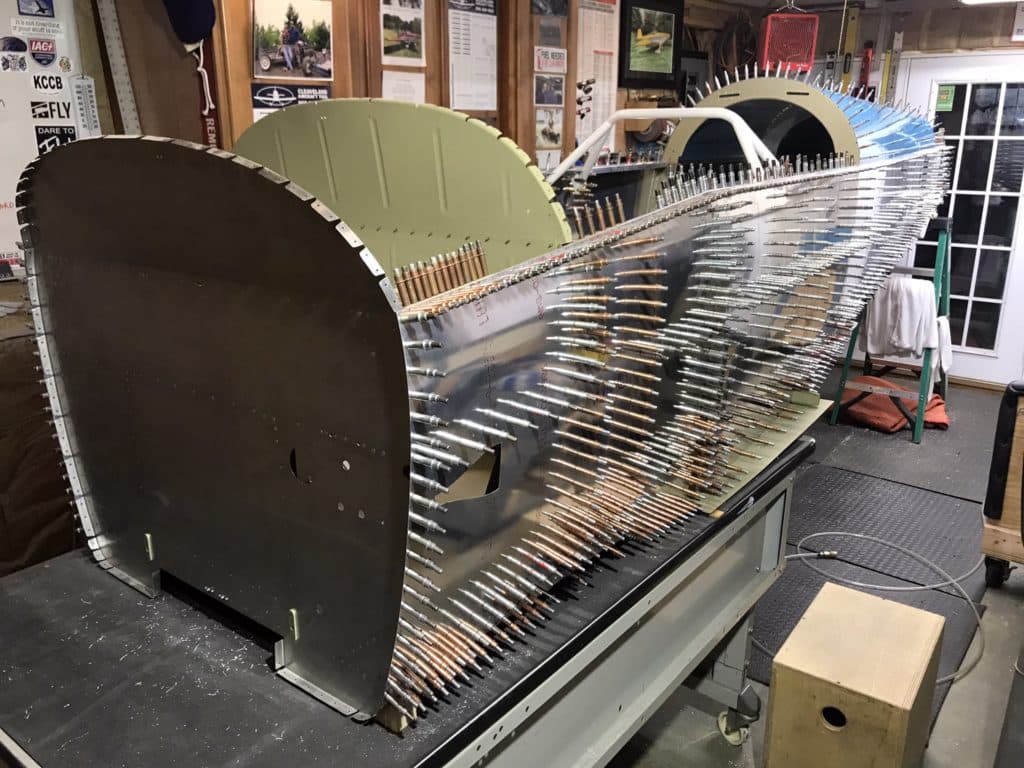

Traditionally, one excellent way to accumulate the required experience was constructing an experimental amateur-built (E-AB) aircraft. But in 2019 the FAA changed the rules in the middle of the game. Change 675 to FAA Order 8900.1 (the FSDO inspector’s handbook) added the following to Volume 5, Chapter 5, Section 5-1134(C): “NOTE: Manufacturing of any type of aircraft, including amateur-built experimental, does not count towards practical experience. However, practical experience gained on amateur-built aircraft after the aircraft has received an Airworthiness Certificate may count.”

Why would the FAA do this? As best I can determine, the change was based on a legal interpretation that an aircraft-under-construction does not legally qualify as a civil aircraft until it receives an FAA airworthiness certificate. This strikes me as a wrongheaded distinction given the wording of 65.77 which calls for 30 months “of practical experience with the procedures, practices, materials, tools, machine tools, and equipment generally used in constructing, maintaining, or altering” airframes and powerplants. Why would the reg say “constructing” if it didn’t really mean it?

At the time, this struck me as an ill-considered change. What better preparation could one have for becoming an A&P than building an airplane? The decision now seems even more unfortunate given the current acute shortage of GA mechanics. Shouldn’t the FAA be encouraging more people to earn their A&P, not throwing up new barriers to entry?

In January 2022, Brenton Ellis of Clarkesville, Georgia requested a legal interpretation of this issue from AGC-200, eloquently pointing out that the 2019 policy change in FAA Order 8900.1 seemed to run afoul of the regulatory language of FAR 65.77. A year and a half later, Ellis is still awaiting that legal interpretation. I hope he receives one soon, and I hope it results in E-AB build time being counted once again as it had been prior to 2019.

I’m not sure why it’s taking so long. Is AGC-200 suffering from a post-COVID staffing crunch? Or is this another a regulatory hot potato?

You bought a plane to fly it, not stress over maintenance.

At Savvy Aviation, we believe you shouldn’t have to navigate the complexities of aircraft maintenance alone. And you definitely shouldn’t be surprised when your shop’s invoice arrives.

Savvy Aviation isn’t a maintenance shop – we empower you with the knowledge and expert consultation you need to be in control of your own maintenance events – so your shop takes directives (not gives them). Whatever your maintenance needs, Savvy has a perfect plan for you: