Is your mechanic a minimalist or a maximalist?

I’m an unabashed maintenance minimalist. I believe in doing only maintenance necessary to make an aircraft safe, reliable, and compliant with regulations. I believe that doing more maintenance than that is not only a waste of time and money, but that it also makes the airplane less safe and reliable.

I think about aircraft maintenance the way I think about surgery—not as a good thing, but as a necessary evil. Sometimes it has to be done, but we don’t get extra credit for doing more than necessary to make the airplane safe, reliable and legal.

This “less is more” maintenance philosophy has served me well for decades, and has become an established science (“Reliability-Centered Maintenance” or “RCM”) widely adopted by airlines, military aviation, high-end bizjets, and industrial activities from nuclear power plants to water treatment plants to offshore oil platforms.

But this philosophy is heresy to many GA mechanics who were taught in A&P school that maintenance is a good thing, and that more maintenance is better. I deal with such “maintenance maximalists” all the time in my managed-maintenance practice. We often wind up having some interesting discussions. Occasionally even an arm-wrestling match.

Owen and Dominic

One of my clients—I’ll call him Owen (not his real name)—owns a Cessna T310 very similar to mine. A very experienced pilot and a longtime aircraft owner, Owen flies his airplane hundreds of hours a year—he literally commutes to work in it—and frequently turns to me for maintenance advice (although he doesn’t always take it).

For years, Owen has taken his airplane to a well-known twin-Cessna specialty shop for annual inspections. The shop’s Director of Maintenance (DOM) is someone I’ll call Dominic (again, not his real name), and he’s an unabashed maintenance maximalist.

Tale of two torque tubes

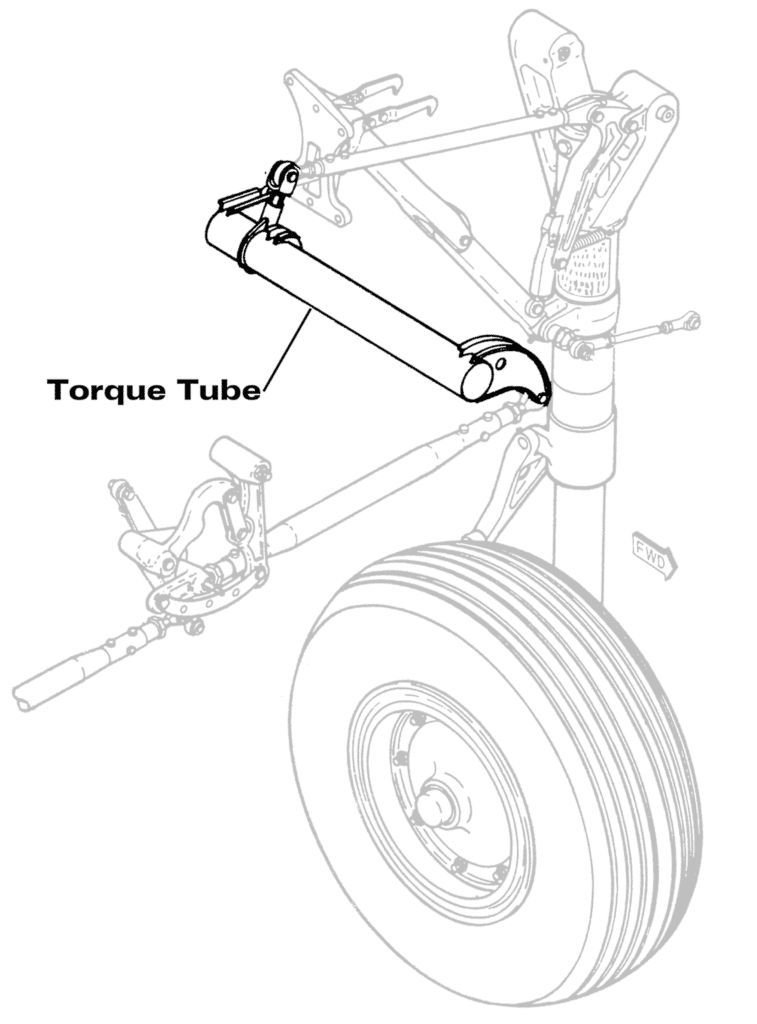

I first became aware of Dom’s maximalist proclivities years ago when Owen phoned me during an annual inspection. Dom told Owen that there was Cessna service bulletin that called for removing the main landing gear torque tubes (Fig. 1) for non-destructive testing (NDT). As a Part 91 operator, Owen was not required to comply with service bulletins, but Dom strongly recommended he comply with this one because the torque tubes had a long history of cracking.

Owen asked if I thought he should have the torque tubes removed and sent out for NDT. Before responding, I decided to do a little research.

I reviewed the FAA Service Difficulty Report (SDR) database looking for reports of torque tube failures. I found plenty, but after reading them it became clear that when the torque tube fails, it always fails at gear retraction, and the result of the failure is that the affected main landing gear remains down and locked. I couldn’t find a single report of a failed torque tube causing a gear collapse or any other sort of collateral damage. I therefore concluded that a torque tube failure was “a failure with acceptable consequences,” and so the optimum strategy is simply to wait until the torque tube fails and then replace it. In RCM-speak, this is called “run to failure.” In plain English, “if it ain’t broke, don’t fix it.”

I phoned three other big twin Cessna specialty shops, spoke to their DOMs, and asked what they were doing about torque tubes. All three told me they were simply inspecting the torque tubes visually without removing them. No one but Dom was sending them out for NDT.

I suggested to Owen that he NOT allow the shop to remove the torque tubes, explaining what I’d found in my research. Owen thanked me for my advice, then called Dominic and approved removal and NDT of his torque tubes. (Sigh.)

When Owen’s torque tubes came back from NDT, one had a red tag on it (meaning unairworthy) and the other didn’t. Dom told Owen that red-tagged one would need to be replaced. In an abundance of caution, Owen asked Dom to replace BOTH torque tubes with new ones. Parts and labor totaled $5,000.

When I heard about this, I asked Owen to retrieve his old torque tubes so I could take a look at them. I carefully inspected the red-tagged one but couldn’t find any sign of a crack. I stripped off the paint and did a dye penetrant inspection, but still couldn’t find anything. I took it to a very experienced A&P/IA colleague, and he couldn’t find anything wrong with it either.

I looked at Owen’s other torque tube, the one that had passed NDT. When I shook it vigorously, it made a rattling sound as if it was full of gravel. I knew what that meant: it was full of rust! My conclusion: The torque tube that passed the NDT test was bad, and the one that flunked was good…go figure.

Fast-forward a year. Owen’s airplane was back at Dom’s shop for its next annual. During the inspection, Dom found that the new torque tubes were dimensionally different from the old ones, and they had been hitting the wing ribs during gear retraction, damaging the ribs. The year-old torque tubes had to be replaced with yet another set of new ones (which Cessna paid for under warranty), and the damaged wing ribs needed repair (which Owen paid for).

Tale of two props

Fast-forward another year to Owen’s next annual. Dom informed Owen that his props were six years old and needed to be sent out for overhaul, an $8,000 event. Dom said there was grease inside both spinners, and concluded that the props had bad grease seals.

Owen asked for my advice. I told him I thought he’d be crazy to let the shop touch those props. I explained that McCauley’s calendar-time TBO recommendation is prompted by concern that a prop that isn’t flown often and is exposed to the elements could develop internal corrosion. But Owen’s airplane flies at least two or three times a week and is always hangared whenever it’s not flying. I felt his props wereat very low risk for corrosion, so there would be little to be gained by tearing them apart.

Knowing that Owen is as much of an NTSB accident report junkie as I am, I asked him “have you ever heard of even a single accident involving the failure of a high-time propeller on a piston aircraft?” He hadn’t. Neither had I. I’ve seen accidents following unreported prop strikes, and a few caused by assembly errors. But high-time props that haven’t hit anything just don’t seem fail.

Owen told Dom he would be declining the prop overhauls, but Dom said he was uncomfortable signing off the annual unless the overhauls were done. Owen asked me what to do. I suggested he offer Dominic the following proposition: If Dom would sign off the annual, Owen would promise to fly the airplane to a nearby propeller shop and have it inspected by a propeller specialist. If the prop specialist felt the prop should be overhauled, then Owen would have them overhauled. Dom reluctantly agreed it and signed off the annual.

A week later, Owen flew his airplane to the prop shop, where the shop owner inspected both props, asked some questions about Owen’s operational habits, and then told Owen that he’d be crazy to overhaul the props. Owen asked about the grease inside the spinners. The prop specialist said the grease looked old, the amount was small, and he wasn’t concerned.

Exhaust system debacle

This year, Owen once again had his annual scheduled at Dominic’s shop. Owen made Dom promise two things: (1) that he’d absolutely, positively get the annual turned around in one week (starting first thing Monday morning, done by Friday afternoon), and (2) that he wouldn’t hassle Owen about overhauling the props. Dominic agreed to both conditions, and Owen dropped off the airplane Sunday evening so it would be there when the shop opened Monday morning. At mid-week, things were looking good. The inspection turned up no major show-stoppers. At last, it seemed as if Owen was going to have a problem-free annual. But alas, it was not to be.

On Friday afternoon, as Owen was about to leave home to pick up his airplane, Dominic phoned. “Owen, I just realized that the exhaust systems on your airplane are 12 years old, and we need to remove them and send them out for recertification per AD 2000-01-16.” Owen was furious that Dominic had waited until literally the eleventh hour to tell him this, and Dom apologized for not having caught it earlier. But AD compliance is non-negotiable, and so Owen authorized Dom to pull the exhaust systems.

Owen called me Saturday to inform me of this turn of events. I was aghast. I explained that the AD was quite explicit that no action was required on the exhaust system until it had accumulated 2,500 hours in-service. After the exhaust had reached 2,500 hours, removal was not required until the next engine overhaul. (Owen’s exhaust systems had 1,800 hours on them.)

Owen reviewed the AD and concluded that I was right. He was livid.

Monday morning, Owen called Dominic to tell him to stop work, but it was too late. The exhaust systems were already off the airplane and had been shipped out for recertification. Dom insisted that the AD required that this be done because the exhaust systems were 12 years old. Owen asked Dominic to call me. I spent a half-hour on the phone walking Dom through the AD (which I’d helped to write in 1999). Dominic was unconvinced, insisting he was right and I was misreading the AD.

Owen called Dominic’s boss who owns the shop. The shop owner read the AD himself, saw Owen’s point, and asked for a little time to research the issue with the FAA. He proceeded to phone the Wichita Aircraft Certification Office and ask for an official ruling. The ACO promised to call him back by close-of-business but never did.

Meantime, the shop owner called several other owners and DOMs of twin Cessna shops to ask their opinions about what the AD required. The answers he got were roughly a 50-50 split, with some agreeing with Dominic’s interpretation (12 years) and others agreeing with mine (next engine overhaul after 2,500 hours).

The next morning, an engineer from the Wichita ACO called back to say that Dominic was wrong and I was right: The AD didn’t require removal of Owen’s 1800-hour exhaust systems. Dominic had the exhaust overnighted back and reinstalled it on the airplane. Owen asked the embarrassed shop owner to “eat” half the cost of the unwarranted exhaust removal and installation, and he agreed. Owen finally retrieved his airplane the following Saturday evening, eight days after the promised delivery date. The annual ordeal was over.

Or was it…

Epilog

Monday morning, Owen called. “How far should my main gear struts be extended when the airplane is on the ground?” About three inches. “My struts are extended at least six inches, virtually full extension.” I suggested he have a local mechanic release some nitrogen from the struts.

Were the struts overextended prior to the annual? No, they were perfect. Did you squawk them? No. Then why would they service the struts? No idea. Were they overextended when you picked up the airplane on Saturday? Yes, but the shop was closed. (Sigh.)

A few hours later, Owen called again. “What’s my fuel flow supposed to be on takeoff?” Ideally 35 to 36 GPH. “I’m getting nearly 40 GPH.” That’s too much, you need to get it adjusted down. Was it that way before the annual? No, it was fine. Was it that way on the Saturday flight back home from the shop? Might have been, I don’t remember, the shop was closed…

In my view, Owen’s story is a perfect illustration of the problem with the maximalist maintenance philosophy practiced by so many shops. Any time you let a mechanic mess with something that’s working okay, you run the risk that he’ll make it worse, not better.

The antidote is simple: If it ain’t broke, don’t fix it. If it isn’t required by regulation and doesn’t compromise safety-of-flight, just let it be.

You bought a plane to fly it, not stress over maintenance.

At Savvy Aviation, we believe you shouldn’t have to navigate the complexities of aircraft maintenance alone. And you definitely shouldn’t be surprised when your shop’s invoice arrives.

Savvy Aviation isn’t a maintenance shop – we empower you with the knowledge and expert consultation you need to be in control of your own maintenance events – so your shop takes directives (not gives them). Whatever your maintenance needs, Savvy has a perfect plan for you: