“I had an oil sample analysis performed in March,” Jay posted on his newly-created SavvyQA ticket for his 1974 Cessna 172. “Aluminum, chromium, iron and silicon were all elevated compared to the previous sample. I flew another 17 hours and took another oil sample in May. Wear metals improved but the lab still expressed some concerns.”

“My A&P performed a borescope inspection,” Jay continued. “All cylinders looked good except for Cylinder #1 (front right) in which my A&P noted pitting and said the barrel looked rusted and flaked away. He said this was likely the reason for the high wear metals in the oil report, and said that if he were in my shoes he’d replace the cylinder (about $3,000 parts and labor). The engine is at only about 400 SMOH.”

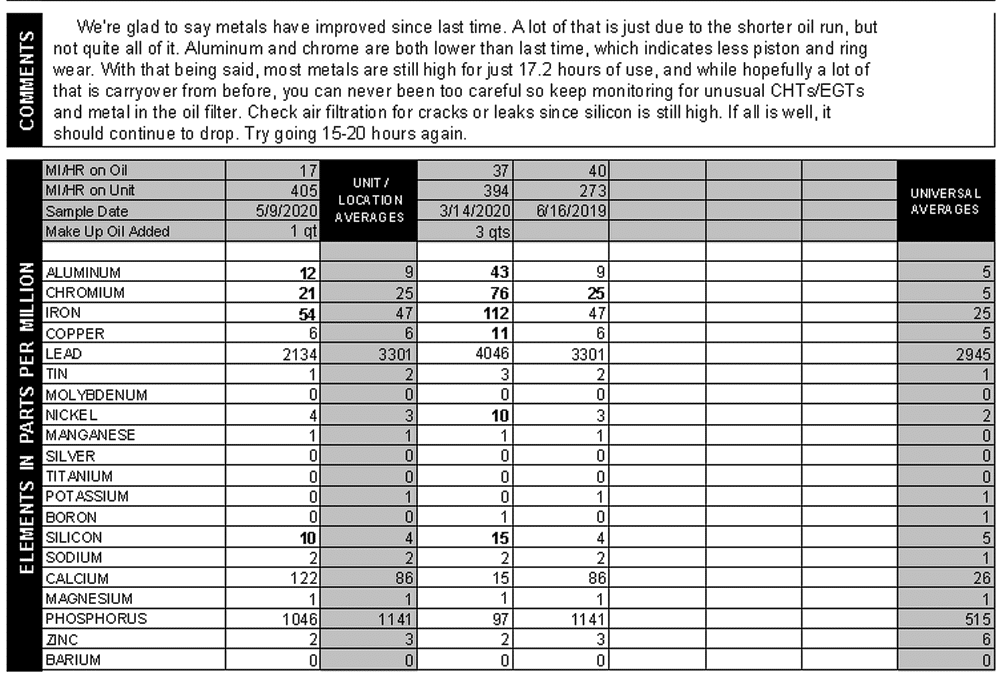

Jay attached the oil report and borescope images to his ticket post. “I would love Savvy’s opinion on whether a cylinder replacement is necessary,” he concluded.

Let’s think about this…

Savvy’s technical director Jeff Iskierka A&P/IA reviewed Jay’s oil analysis report. It was true that several wear metals were higher than we’d like to see them in the March report (though less so in the June report). The March report showed iron at 112 parts-per-million (ppm). Lycoming’s threshold of concern for iron is 100 ppm, so 112 ppm is worrisome but not horrifying. The value came down to 54 ppm in May, and that sample undoubtedly contained considerable carryover from March (since there’s quite a bit of undrainable oil at the oil change), although on the other hand only 17 hours were flown between samples.

Whenever we see elevated iron, the first thing we ask ourselves is “was this engine inactive?” Steel cylinder barrels almost always rust during periods of disuse—particularly in humid climates like the DFW area where Jay is based—and that rust scrapes off when the engine is run and shows up as elevated iron in the next oil sample. Jeff asked Jay about this, and Jay admitted that the airplane had been down for a month and a half for its annual inspection and then sat awhile longer while a new GPS navigator was being installed in the panel. That seemed to explain the elevated iron.

But what about the elevated aluminum, chromium and nickel? Disuse couldn’t explain those. What could cause all three of those wear metals to spike simultaneously? The most obvious thing that could do exactly that would be dirt in the oil, because dirt turns oil from a lubricant into a grinding compound that invariably causes all wear metals to rise.

Sure enough, the March report showed silicon at 15 ppm, about three times what it should be. No question that excessive amounts of dirt was getting into this engine, and that certainly explains why all the wear metals went up.

How did dirt get into the engine? While it could be a bad induction air filter, our experience is that the most common cause of dirt-in-the-oil syndrome is a carburetor heat or alternate air door that isn’t sealing properly, allowing the engine to breathe unfiltered air. This is the sort of problem that can go undetected for months, even years, unless the engine is on an oil analysis program and somebody notices that silicon is elevated (usually along with a bunch of wear metals).

This is just one reason we’re such big believers in laboratory oil analysis at Savvy. The value of an oil analysis report is comes from looking at microscopic particles of metal suspended in the oil. Those microscopic particles can give very early warning of issues (like dirt getting into the oil) that wouldn’t show up in any other way until much later.

But microscopic particles of metal suspended in the oil aren’t going to make you fall out of the sky, no matter how many of them there are. Unless there’s a significant quantity of visible metal in the oil filter or suction screen or something seriously worrisome that shows up under the borescope, we would never consider doing something as invasive and risky as cylinder removal no matter how ugly the oil analysis report is.

Borescope Revelations

So, what did the borescope reveal about Jay’s #1 cylinder? Jeff studied the still images and movie attached to Jay’s ticket. What he saw looked like a well-worn cylinder with some corrosion pitting visible and no crosshatch left.

This cylinder barrel certainly looked to be in worse condition than what Jeff expected to see in a 400-hour cylinder. It looked more like a 1500-hour cylinder. But Jeff had seen a lot worse. And these Lycoming cylinders have been known to go 3,000-4,000 hours without any issues. In short, what Jeff saw in the borescope images wasn’t pretty, but it wasn’t dangerous, either. Certainly nothing that would prompt a recommendation to pull the cylinder, something that would involve a lot more risk than leaving it alone in Jeff’s judgment.

What accounted for this cylinder’s old-before-its-time appearance? Hard to say. Perhaps the engine’s history of irregular use and extended inactivity contributed. Maybe dirt-in-the-oil syndrome did, too. It’s even possible that when the engine was field overhauled 400 hours earlier, the engine shop installed an overhauled #1 cylinder rather than a new one.

Just because the cylinder looked a bit long in the tooth was no reason to euthanize it, Jeff thought. As long as the cylinder passed its annual compression test, oil consumption wasn’t excessive, and the oil filter and suction screen were free of any substantial accumulation of metal, Jeff couldn’t see any reason to mess with it.

Jeff’s Advice

“No way would I pull a cylinder for any of this,” Jeff told Jay. “The oil analysis is reflecting rust being scraped off the cylinder walls due to inactivity, plus elevated wear metals caused by dirt in the oil. The borescope is showing corrosion pitting and wear, but nothing dangerous.”

Jeff offered Jay a number of suggestions: Fly more often and more regularly. Find out how dirt is getting into the engine (starting with an inspection of the carb heat door and induction air filter) and fix it. Change the oil more often until oil analysis results start to normalize. Use CamGuard additive to inhibit rust.

Rusting of the cylinder walls is a nuisance, but not a safety hazard. Rusting of the cam and lifters is much more serious (at least to your wallet), because correcting that requires an engine teardown. Jeff urged Jay to take corrosion seriously—but not so seriously as to let his A&P pull the cylinder without a much better reason than what the oil report and borescope images revealed. “Way too many cylinders are removed for no good reason,” Jeff added.

Jeff advised Jay to keep monitoring, keep flying and keep that #1 cylinder firmly bolted to the engine. Jay promised to do exactly that.

Jay’s decision to enroll his Skyhawk in Savvy’s maintenance consulting program (SavvyQA) cost him $375/year. Just this one question alone saved him at least $3,000 in unnecessary maintenance expense, not to mention the risk involved in an invasive and inappropriate cylinder transplant. That savings was enough to pay for his SavvyQA subscription for the next eight years.

This isn’t unusual. Savvy’s zealous advocacy on behalf of our aircraft-owner clients has become legendary. We almost always save our clients more in reduced maintenance cost than the annual fees they pay to subscribe to our maintenance consulting (SavvyQA) and management (SavvyMx) services. Often a LOT more!

Wouldn’t YOU feel better knowing that Savvy’s technical team had your back? Learn more about SavvyQA.

You bought a plane to fly it, not stress over maintenance.

At Savvy Aviation, we believe you shouldn’t have to navigate the complexities of aircraft maintenance alone. And you definitely shouldn’t be surprised when your shop’s invoice arrives.

Savvy Aviation isn’t a maintenance shop – we empower you with the knowledge and expert consultation you need to be in control of your own maintenance events – so your shop takes directives (not gives them). Whatever your maintenance needs, Savvy has a perfect plan for you: