How NOT to lean your engine.

At my July pilgrimage to EAA AirVenture in Oshkosh, I had the opportunity to speak to thousands of pilots and aircraft owners on a wide variety of subjects ranging from reliability-centered maintenance to TBO busting to corrosion, and to conduct a half-dozen informal hour-long Q&A sessions addressing whatever maintenance-related issues were on their minds. In those sessions, I received more questions about one topic than all others combined: leaning.

Some of the questions focused on Old Wives’ Tales about lean-of-peak (LOP) operation:

Q: Won’t operating LOP hurt my engine, burn my exhaust valves, etc.?

A: It’s a lot easier to damage your engine ROP, much less likely LOP.

Q: Can my carbureted engine be operated LOP?

A: Most can. Using carb heat helps. Only way to know is to try it. You can’t hurt anything by experimenting with LOP operation.

Q: Can my injected engine be operated LOP without GAMIjectors?

A: Some can, some can’t. Only way to know is to try it. You can’t hurt anything by experimenting with LOP operation.

Q: Can my engine be operated LOP without an engine monitor?

A: Sure. I operated LOP for a decade before I installed my engine monitor. Now, I think it’s really important to install an engine monitor, but that’s true regardless of whether you run ROP or LOP.

Q: I’ve experimented with LOP, but I find that my EGTs are much higher when I run LOP than when I run ROP.

A: That’s true. Why does that concern you? High EGTs are not damaging to your engine. It’s high CHTs that are damaging to your engine. And LOP operation almost always results in lower CHTs.

Other questions focused on “the right way to lean” and sought cookbook answers:

Q: How many degrees LOP should I operate my engine?

A: That depends on many variables: power setting, altitude, temperature, etc. The answer might be anywhere from 0°F LOP and 100°F LOP.

Q: How many degrees LOP do you operate your own airplane?

A: I don’t have a clue. I never use EGT as a leaning reference, so I don’t know how many degrees LOP I operate. All I know is that it varies all over the place depending on various conditions, and it’s not a particularly interesting number so I don’t worry about it.

The problem with questions like this is that they are based on the misconception that there’s “a right way” to lean an engine. In fact, there are lots of different “right ways” to lean an engine, and I employ them all from time to time.

In my turbocharged Cessna T310R I mostly climb very ROP, but occasionally I climb LOP when that’s appropriate. I mostly cruise LOP, but it varies from slightly LOP to profoundly LOP depending on cruise altitude, OAT, and whether my objective is speed or fuel economy. I have thousands of hours flying Cessna 182s, and most of that time was spent neither ROP or LOP but rather right at peak EGT (and at appropriately reduced power). When I fly a Super Cub, I lean to the onset of engine roughness and I haven’t a clue whether I’m ROP or LOP. All of these ways of leaning are “right ways.”

The key to leaning is not doing it “the right way” because there are so many different right ways to lean. Rather, the important thing is to avoid doing it “the wrong way” by avoiding situations that are potentially damaging or abusive to the engine.

The Red Box

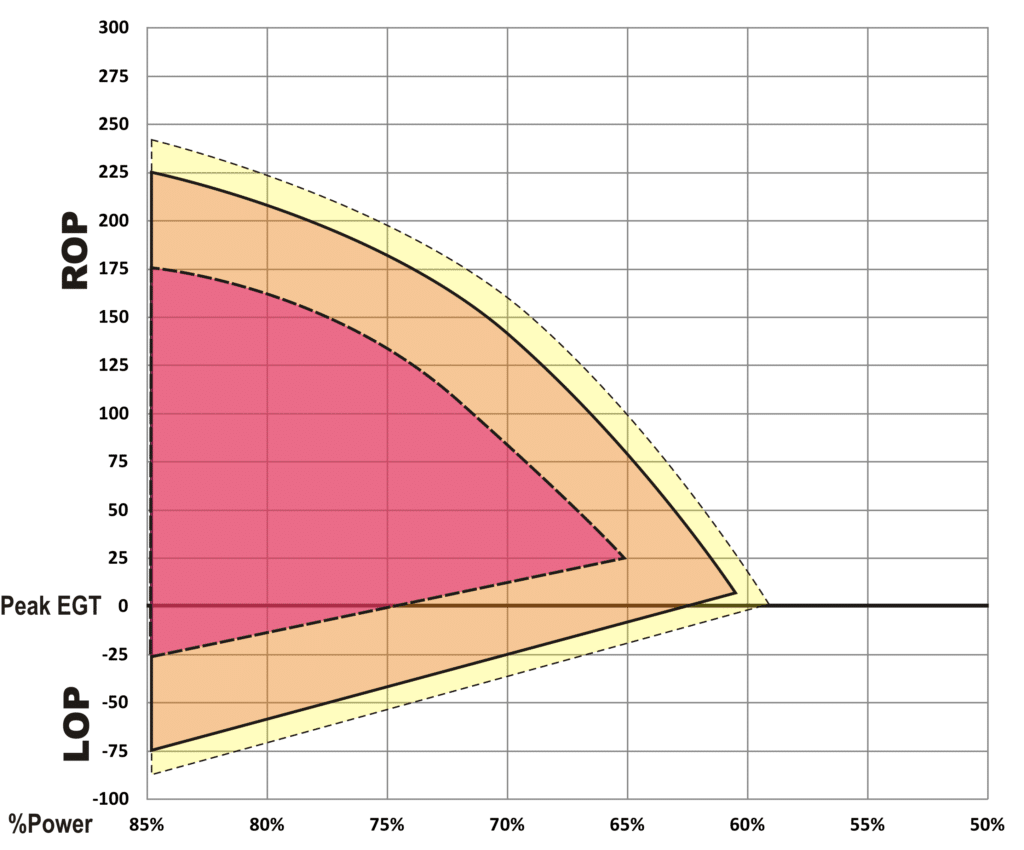

My friends George Braly, John Deakin and Walter Atkinson of Advanced Pilot Seminars fame developed an important conceptual tool for conveying this idea. They call it “the red box” because it’s generally depicted as a red-tinted rectangle superimposed over a graph of various engine landmark parameters (EGT, CHT, ICP, HP, BSFC) plotted as mixture is varied from full-rich to extremely LOP. The red box depicts the range of mixture settings that result in excessive internal cylinder pressures (ICP) and therefore should be avoided. Mixture settings outside of the red box—whether on the rich side or the lean side—are all fair game.

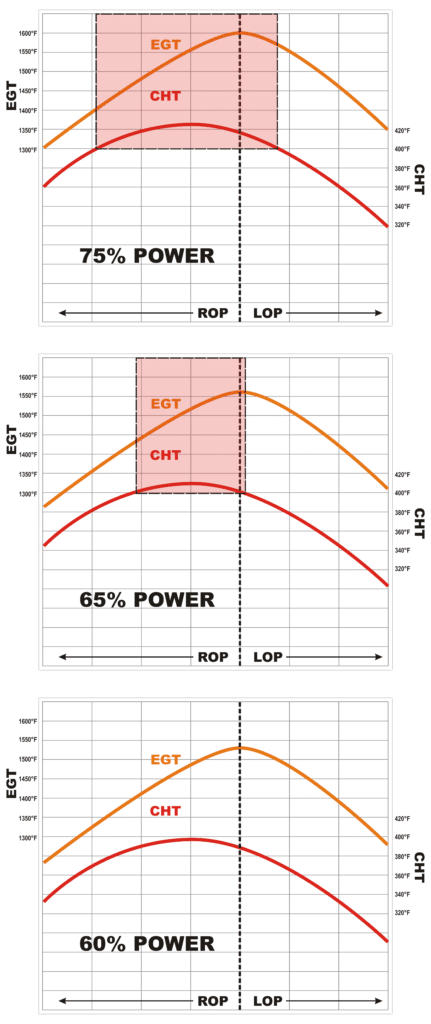

The width of the red box varies with power (see Figure 1). The lower the power, the narrower the red box becomes. At sufficiently low power (generally somewhere between 60% and 65% for most engines), the red box disappears completely, and you can run the engine at any mixture you like without abusing anything.

One practical problem with the red box concept is that it’s based on limiting internal cylinder pressure (ICP), but unfortunately we don’t have an ICP gauge in our cockpits. It sure would be nice if we did, because it would make leaning pretty much of a no-brainer. In the GAMI test cell in Ada, Oklahoma, they instrument ICP by installing special “tricked out” spark plugs that contain pressure transducers capable of measuring instantaneous combustion chamber pressure. Sadly, we don’t have these in our aircraft because the transducers are god-awful expensive and the tricked-out spark plugs aren’t certified.

In the absence of an ICP gauge, the best proxy for ICP we have in the cockpit is CHT. The good news is that the ICP and CHT curves have the same shape and peak at the same mixture. The bad news is that CHT is affected not only by ICP but also by several other factors that don’t vary with mixture (notably OAT, IAS, density altitude and cooling system efficiency).

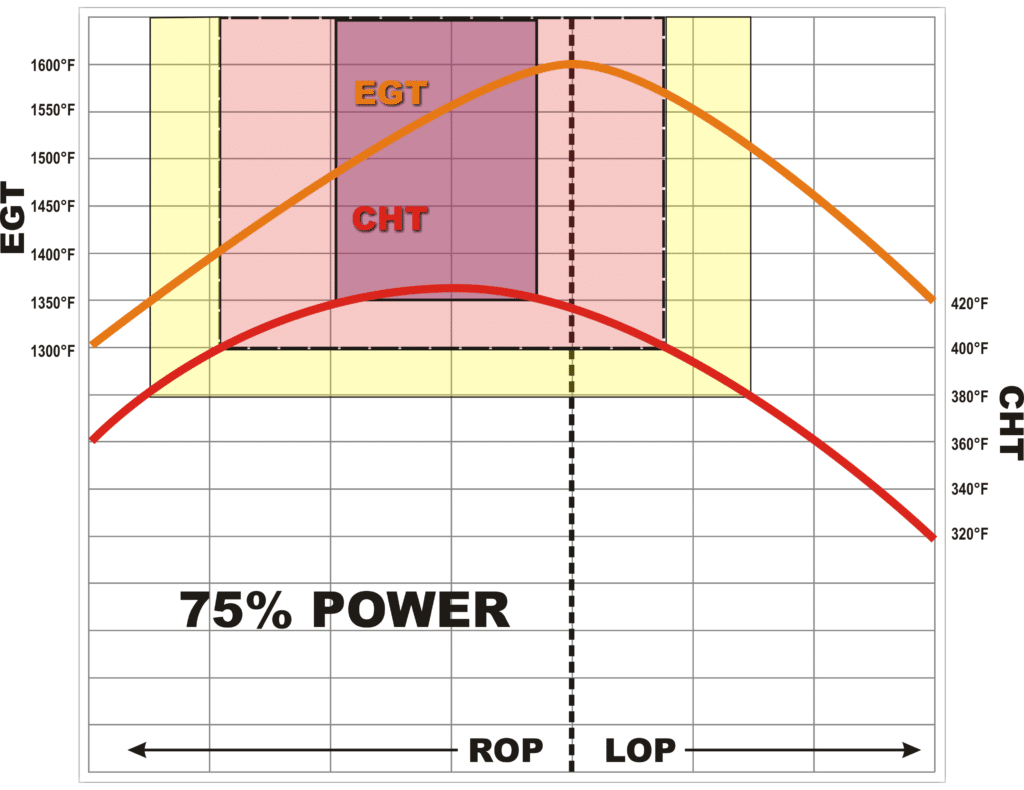

Figure 1 depicts the red box as encompassing all mixtures that result in CHTs above 400°F, and that’s probably appropriate for most legacy aircraft when the OAT is at standard temperature (ISA) or greater. But if the OAT is colder than ISA or if the aircraft has a particularly efficient cooling system design (e.g., Cessna Corvallis, Cirrus SR22, Diamond DA40), the maximum acceptable CHT is lower and the red box needs to be wider.

Another problem with the red box concept is that it suggests that all mixture settings inside the red box are equally bad. That’s obviously not true; the higher the ICP (and CHT), the more abusive the mixture. For this reason, I think it’s useful to think of the red box has having a purple zone in the center depicting the mixtures that are ultra-abusive and to be avoided at all costs, and a yellow cautionary zone around the edges depicting a cautionary buffer zone to be avoided when possible for maximum engine TLC. (See Figure 2.)

The Red Fin

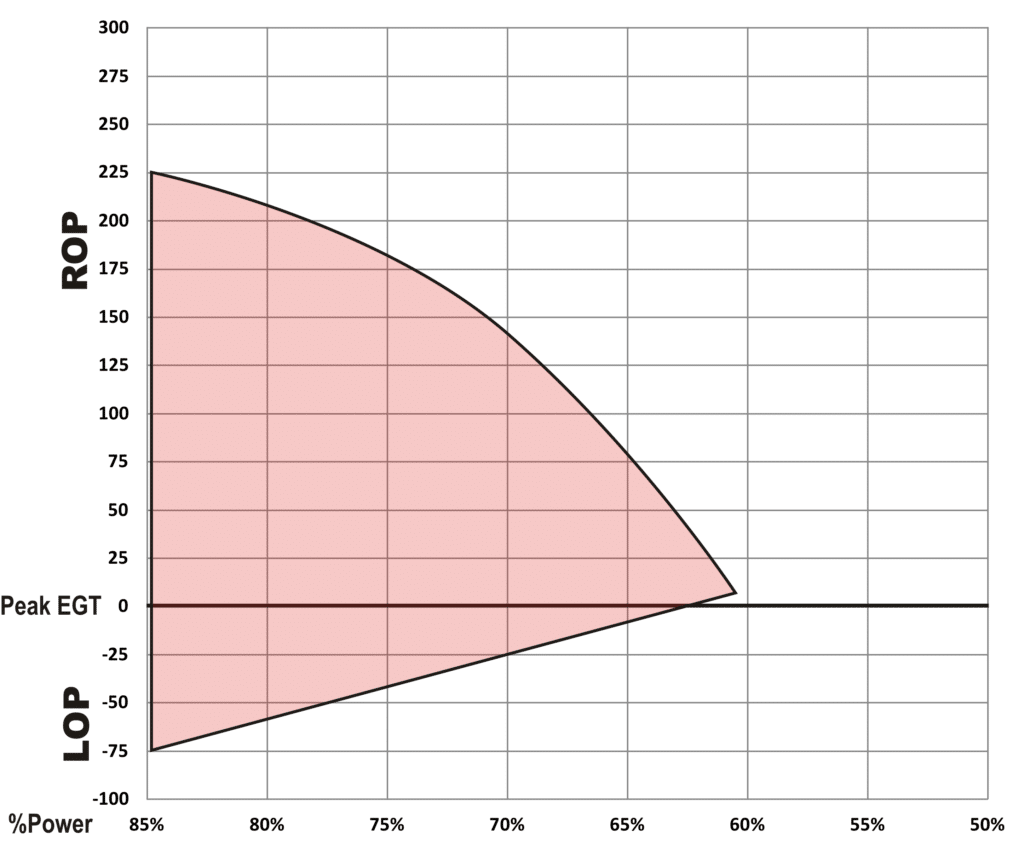

Perhaps an even more useful variant of the red-box concept one that has been popularized in the Cirrus community by my friend Gordon Feingold, but is relatively unknown in non-Cirrus circles. (See Fig. 3.) It is called “the red fin” and emphasizes that the width of the red box varies dramatically with power, and disappears altogether when power is reduced sufficiently.

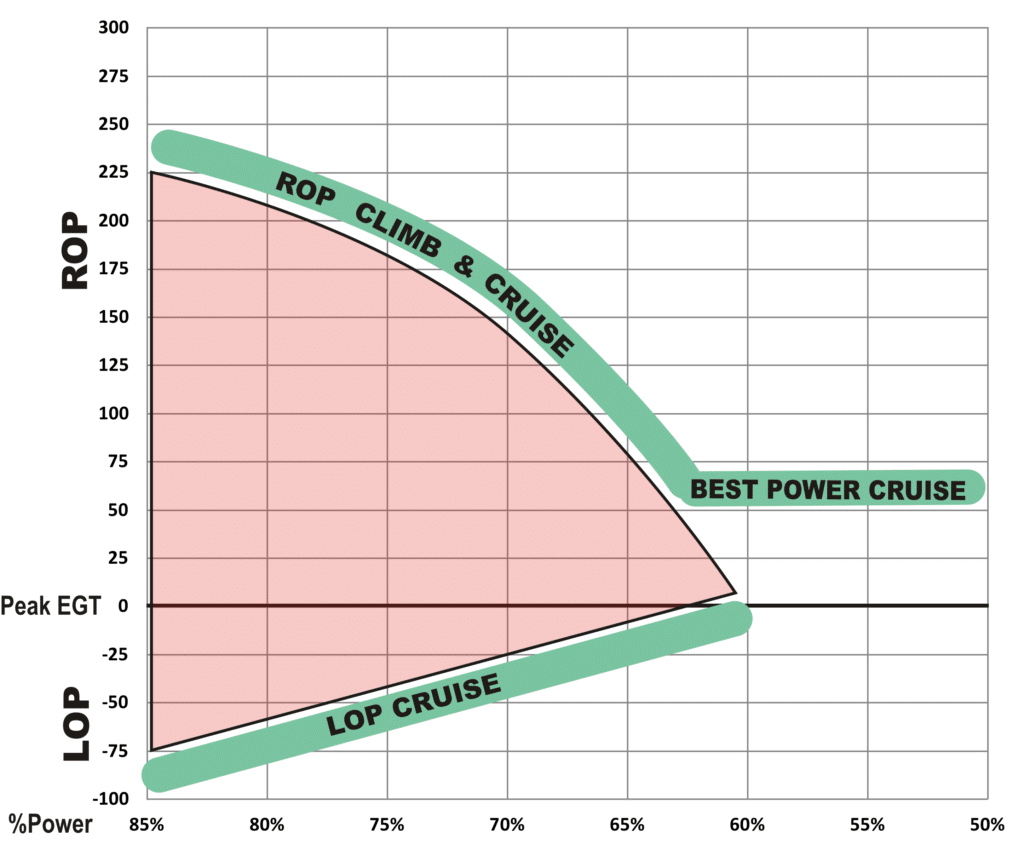

Like the red box, the red fin depicts mixture settings that are abusive to the engine. Settings outside the red fin—whether ROP or LOP—are fair game. Figure 4 depicts the three most useful outside-the-red-fin zones for climb and cruise. ROP mixtures are above the fin, and LOP mixtures are below it. At low power settings where the fin disappears, best-power mixture occurs at roughly 75°F ROP.

As with the red box, the red fin suggests that all mixtures inside the fin are equally abusive, but that’s obviously not true. Figure 5 shows a modified red fin chart with a purple zone depicting ultra-abusive mixtures, and a yellow cautionary buffer zone to be avoided when feasible.

Flying the Fin

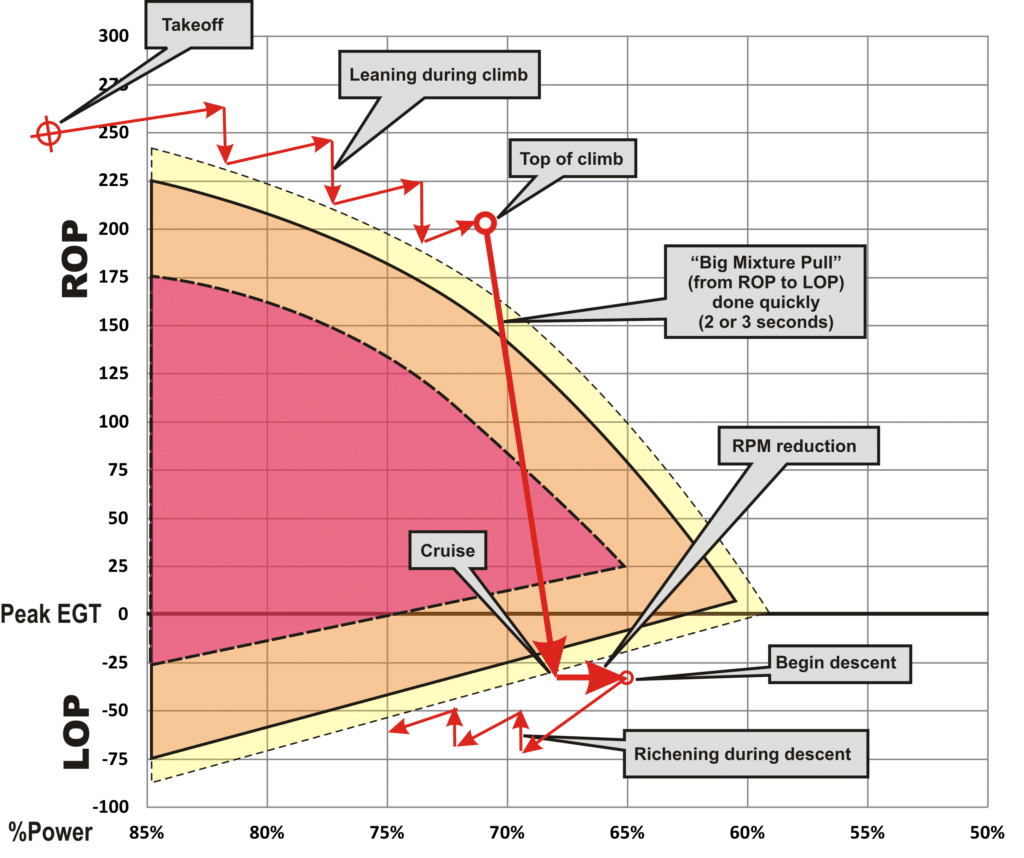

Figure 6 illustrates how we can use the red fin concept as a guide to mixture management throughout all phases of flight. It depicts one method of managing the mixture, but certainly not the only method. (Remember, any mixture that lies outside the red fin is fair game.) It also assumes a normally-aspirated engine with a conventional non-altitude-compensating fuel system. (Turbocharged engines and engines with an altitude-compensating system are a bit simpler to manage because you don’t need to adjust the mixture during climbs and descents.)

The flight starts when takeoff power is applied at full-rich mixture (which is typically at least 250°F ROP for most properly-adjusted engines). We remain at wide-open throttle and let Mother Nature take care of reducing manifold pressure as we climb. With most engines, this results in a mixture that gets progressively richer with increasing altitude and decreasing MP, so from time to time we lean the mixture manually to keep it “in the zone” on the rich side of the red fin. (In my turbocharged airplane, I don’t need to do this because MP doesn’t decrease as I climb so there’s no need to touch the mixture.)

When we reach top-of-climb, level off, and commence the cruise phase of the flight, we perform a “big mixture pull” to transition from ROP to LOP. This should be done quickly to minimize the amount of time spent inside the red fin (and especially the ultra-abusive purple zone). About 2 or 3 seconds is about right for the BMP. Note that we lose a bit of power as we transition from ROP to LOP; that’s normal and expected, and will be reflected by a small loss of airspeed.

I recommend NOT using the “lean-find mode” of your engine monitor when doing this, because this requires you to lean very slowly in order to locate peak EGT. That results in spending a considerable amount time inside the red fin (and the dreaded purple zone), which is exactly what you DON’T want to do. If you feel compelled to locate peak EGT, it’s much better to perform a quick BMP to get into the LOP zone below the fin, and then slowly richen to locate peak EGT from the lean side.

Personally, I don’t care about locating peak EGT, so I skip this step altogether. I just do a quick BMP to a known-safe LOP fuel flow—or until I hear and feel a small power loss that tells me I’m safely LOP below the fin—and then fine-tune the mixture using either CHT or my fuel totalizer as a primary reference.

As we begin the descent phase, we remain LOP below the fin. Because MP increases with decreasing altitude, the mixture becomes leaner and so from time to time we richen the mixture to prevent it from getting so lean that the engine starts running rough. If we forget to richen, no problem: The engine will remind us. (Once again, I can skip this step in my turbocharged airplane because MP remains constant during the descent.)

Because our airplanes aren’t equipped with ICP gauges, the red box and red fin can provide only approximate guidance. Without ICP information, we can’t know the box or fin boundaries precisely. But as conceptual guidelines, they’re close enough. If we keep them in mind and make a conscious effort to stay out of the red zone (and especially out of the purple zone) for more than a few seconds at a time, we will be rewarded with maximum engine longevity and reliability, and minimum maintenance expense.

You bought a plane to fly it, not stress over maintenance.

At Savvy Aviation, we believe you shouldn’t have to navigate the complexities of aircraft maintenance alone. And you definitely shouldn’t be surprised when your shop’s invoice arrives.

Savvy Aviation isn’t a maintenance shop – we empower you with the knowledge and expert consultation you need to be in control of your own maintenance events – so your shop takes directives (not gives them). Whatever your maintenance needs, Savvy has a perfect plan for you: