One of my favorite movie scenes is early in The Hunt for Red October when sonar expert Jonesy tries to convince sub Captain Mancuso that a sound pattern was mechanical and not “whales humping”. Spoiler alert: it’s the Red October’s advanced “caterpillar” propulsion system. When we get engine data, we have to decide if the pattern we’re seeing indicates engine trouble, or is made by a failing sensor or a loose connection. Savvy’s philosophy is that pilots and owners should be able to monitor and interpret engine data – pilots in real-time and owners when it’s time for maintenance. This monthly Puzzler is designed to help pilots and owners sharpen that skill.

We also see patterns in borescope pictures. We don’t have sensor failure or loose connections, but sometimes too much or too little light can complicate the process. Here’s a set of pictures from a Beech Bonanza powered by a Continental IO-550 engine. Fortunately, this set of pictures didn’t arrive with lighting or focus issues. Unfortunately, the news is not good for the engine.

Good CHT depends on heat dispersion from good contact between the exhaust valve and its seat. In these pictures, we see gaps in the seat which result in exhaust gas escaping in a waterfall-type method. These are cylinders 3 and 4. Let’s look at the data.

That spike just to the right of the cursor is a drop in FF corroborated by a drop in EGTs and CHTs. I thought maybe he had run a tank dry, but the fuel level data shows plenty of gas in both tanks at that point. So we’re not sure why there’s a drop. Getting back to the valve issue, we’re not seeing the typical oscillation in EGT that we see when a burned spot turns in service – aka FEVA. If there are multiple burned spots on a valve, we wouldn’t see that oscillation. Here’s one of the valve heads. Lighting is poor but you can see the multiple spots.

This is why we worked so hard to add borescope analysis to our service last year. The data by itself did not flag these problems.

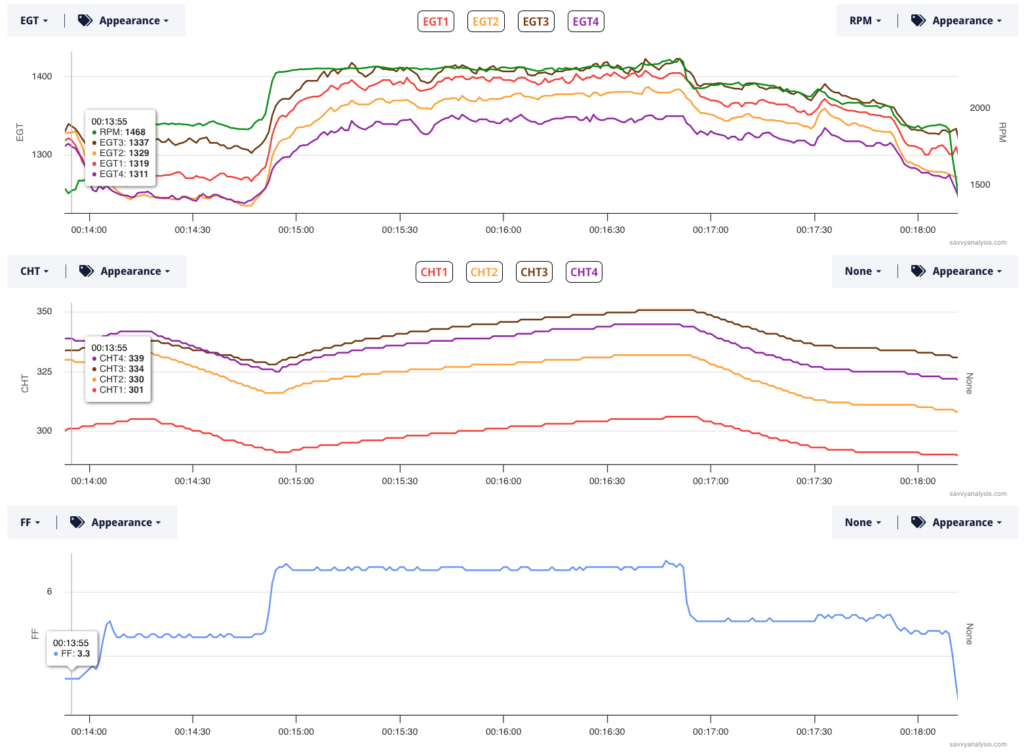

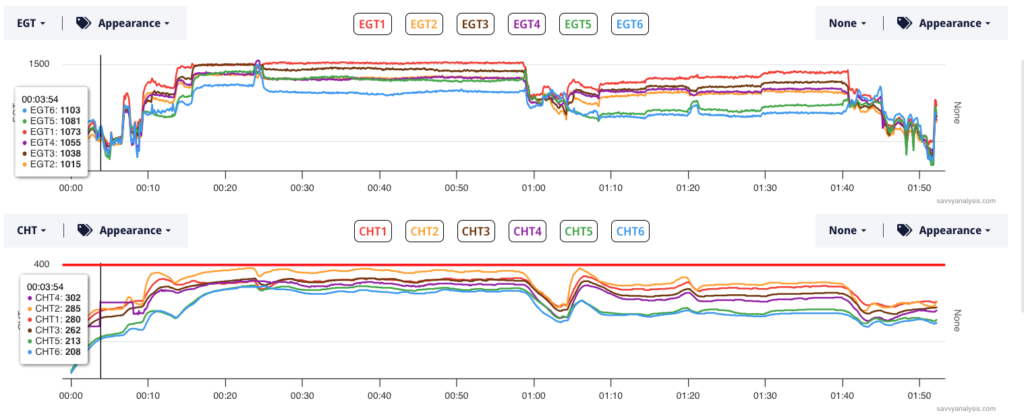

Here’s data from a Pitts S-1C powered by a Lycoming IO-320 and data from a JPI 830 with a 1 sec sample rate. EGTs, CHTs and FF. Nothing special about cursor placement- just out of the way.

Here’s what our client submitted —

My engine will “miss” at lower rpms, in flight, say between 1400 and 1800 or so. It’s like I’m turning off the mags for a split second. I can hear it, and the whole airplane rocks momentarily when it happens. Idle seems fine, runup is fine, higher rpms are fine. But it’s in that midrange that there’s something going on.

Engine has 620 hrs on it, fuel servo overhauled at 460 hrs in 2012, Plugs cleaned and gapped at last annual, mags replaced with new Slick 4517-40s at 402 hrs in 2012, ignition harness replaced at that time as well. Timing of both mags verified at 25, compressions are in the 70s. When the engine is doing this missing thing I’ve tried turning on the fuel boost pump, as well as richening and leaning the mixture. None of those have any effect.

EGTs are at their jumpiest in the 10-15 min segment. But RPMs and FF are nearly idle there, so let’s zoom in to the 15-18 min segment where the client reported the “miss”. Again, cursor just out of the way.

My colleague Ray suggested checking for an induction leak. Client reported —

Ok, here’s the latest troubleshooting we did. Pulled the air box off the RSA injector and put a shop vac on blow mode up against it. With soapy water in a spray bottle I sprayed every intake joint and saw no bubbles, until I sprayed the throttle shaft on the injector.

Here’s a screen grab from the video.

Soapy water found the leak. Time to OH the fuel servo.

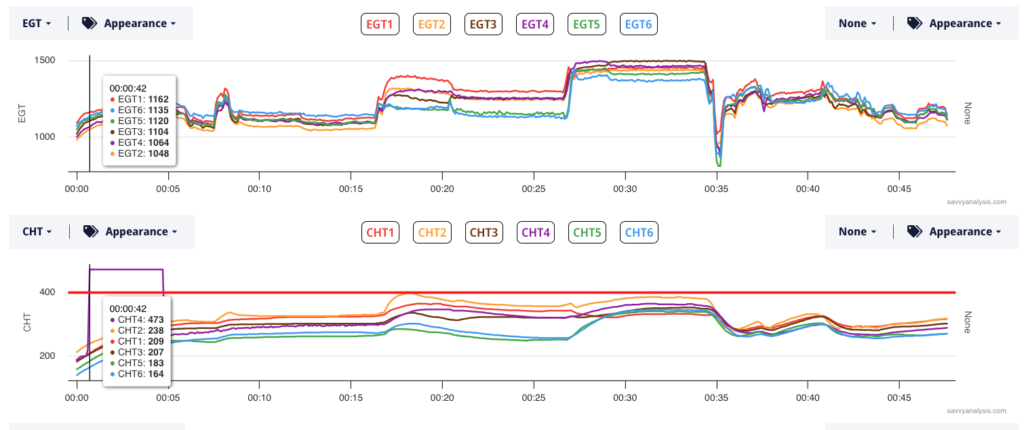

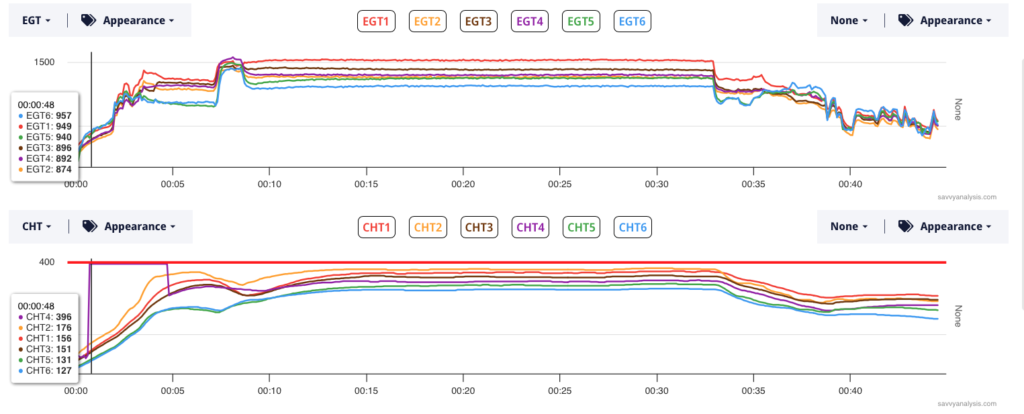

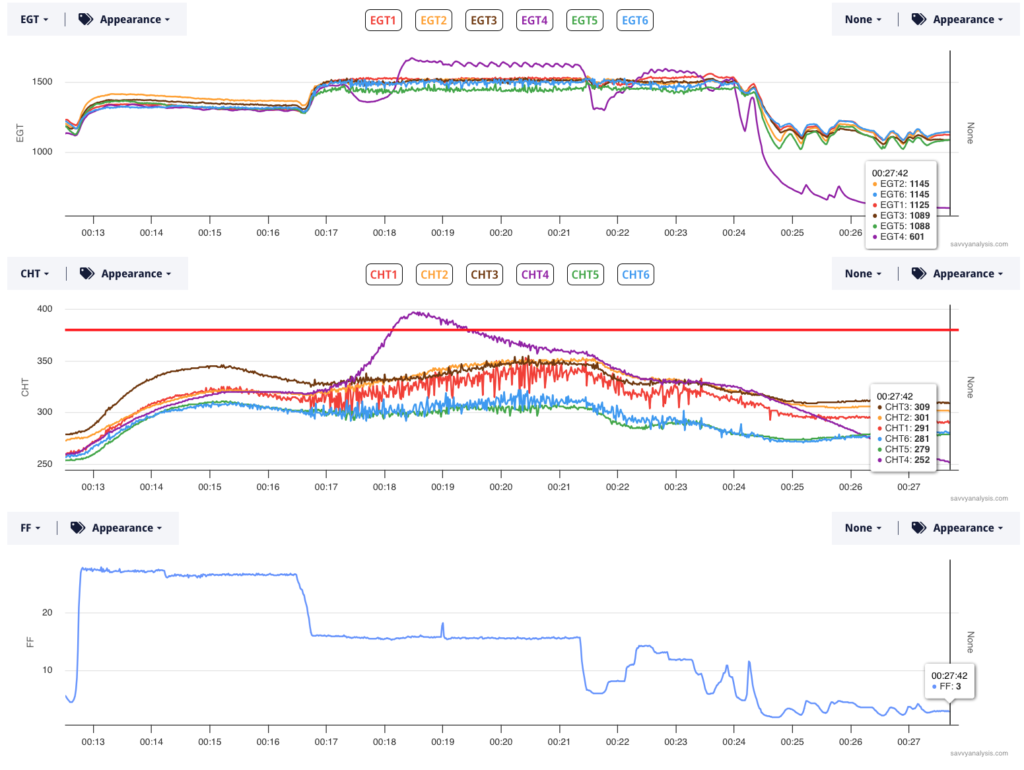

Here’s data from a Cessna 182 powered by a Continental O-470 with data from JPI 830 with a 1 sec sample rate. Here are four recent flights – EGTs and CHTs. Cursor is on the beginning of the CHT 4 excursion in each case.

Well, you’ve gotta give the little probe points for consistency. Always just after engine start, never in flight. Jumps up, stays there, then resumes without a hitch. It always makes sense to check the connection first but in this case, we think it’s a probe failure. A very considerate failure.

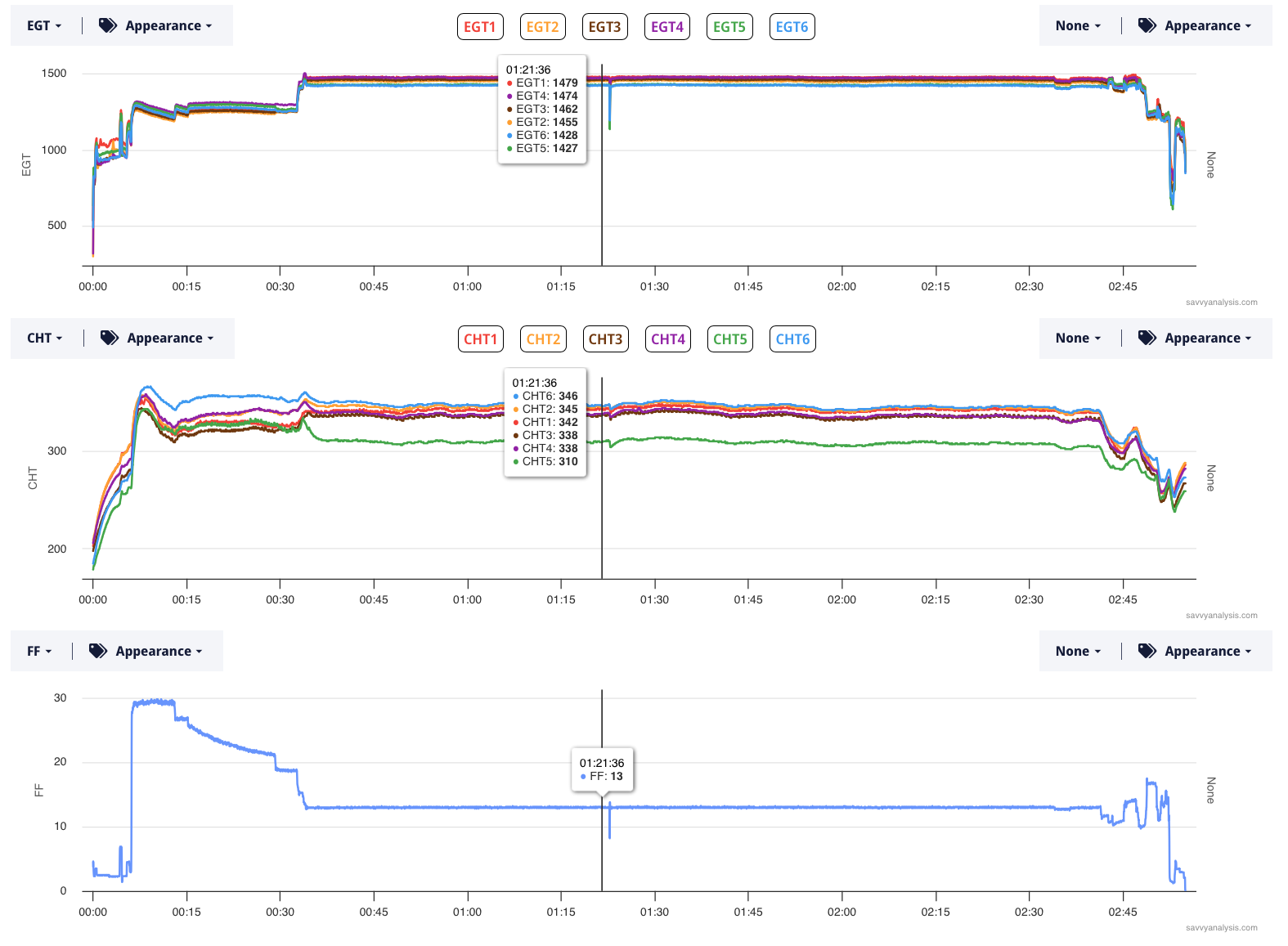

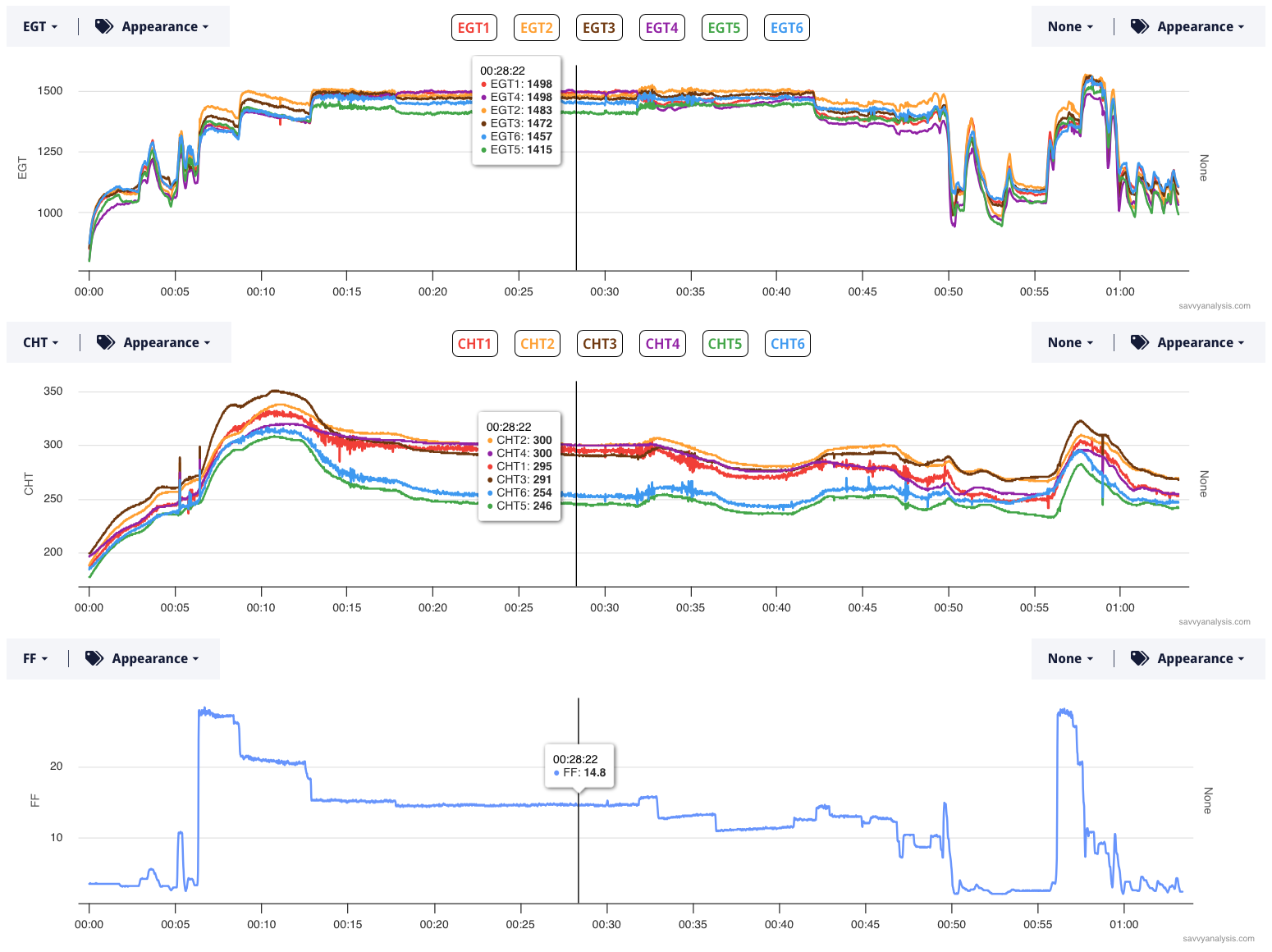

Here’s data from a Piper Saratoga powered by a Lycoming IO-540 with data from an Insight G4. Here are EGTs, CHTs and FF from a recent uneventful flight.

And here’s data from the next flight.

Let’s zoom in to the last half of the flight, starting at the takeoff roll.

With events like these we all want to know “could I have seen this coming?” There’s a very slight oscillation in EGT 4 – the purple trace – in initial climb. from 13 to 16 mins. When FF is reduced, a detonation event begins, including the trademark EGT drop and CHT excursion. Not all detonation events end with catastrophic valve failure. This one did.

See the little FF spike at the 19 min mark? Would a more aggressive FF response to end the detonation event prevented the valve from failing in flight? No way to know…