Your maintenance shop’s paperwork can make all the difference between a good outcome and a nightmare.

When he contacted me, the owner of a pristine turbonormalized A36 Bonanza seemed obviously frustrated:

I manage to fly only 50 to 75 hours a year, but my annual inspections have been running between $8,000 and $12,000 every year despite my low flying time. I think my mechanic is very honest and thorough, but I think he spends about 100 hours doing the inspection. Perhaps he is overdoing it?

I asked the owner to fax me his invoices from this shop for the past two years so I could review them. He did, and when I reviewed the invoices, I found them profoundly disturbing.

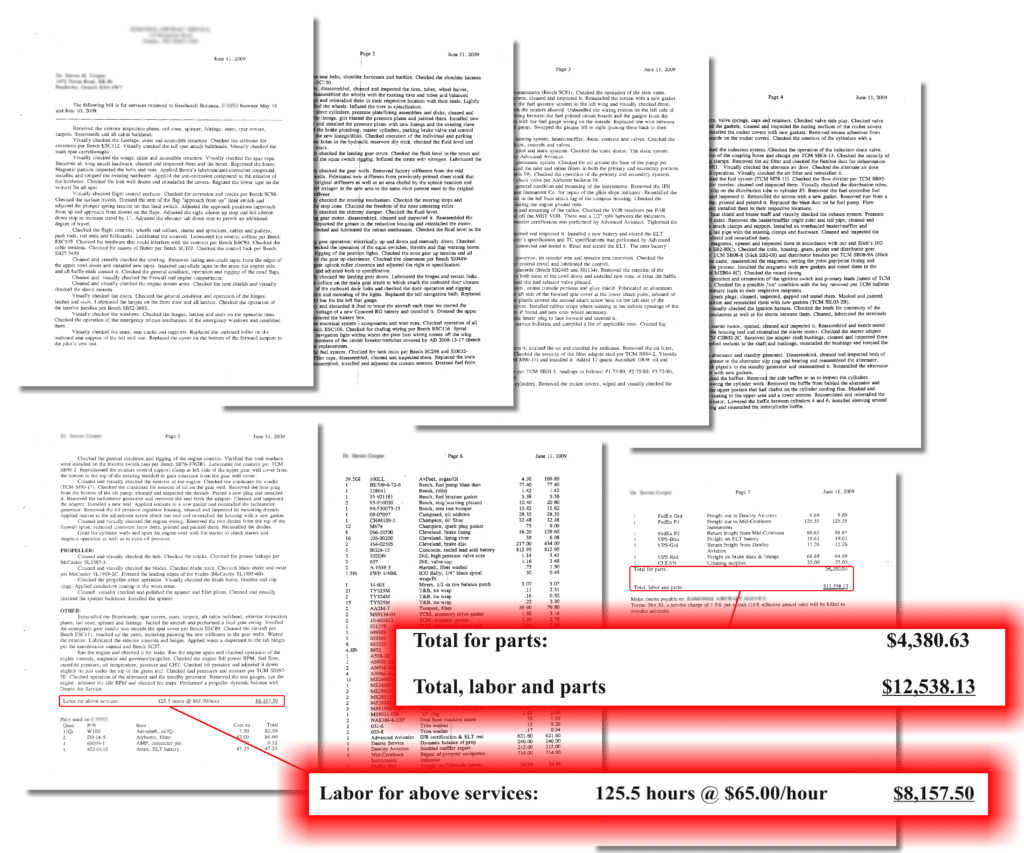

It wasn’t just the totals that bothered me—about $7,000 for the 2008 annual and more than $12,500 for the 2009 annual—but the obscure, perhaps even intentionally cryptic nature of the invoices that made them almost impossible to evaluate. I’ve been looking at maintenance invoices for more than two decades, but these were perhaps the most inscrutable I’ve ever encountered. Let me show you what I mean:

This invoice contains an astonishingly detailed description of the work performed that goes on for five full pages of dense, single-spaced text, followed by a single invoice line-item documenting 125.5 hours of labor at $65.00/hour for a total labor charge of $8,157.50.

There is absolutely no breakdown of how much labor was expended on each maintenance task. There is no information about how much of this labor was devoted to inspection and how much to repairs. There is no information about which of the repairs were “airworthiness items” required by regulation or required to make the airplane safe to operate, and which repairs were “recommended” or “discretionary” that the owner could choose to approve or decline. I find an invoice like this is both unacceptable and unprofessional.

I asked the owner whether the shop had quoted him a flat-rate or estimated charge for “the inspection part” of the annual. He said no.

I asked the owner whether the shop had presented him with a discrepancy list after the inspection was completed, discussed repairs of those discrepancies, estimated the cost of those repairs, and obtained owner’s approval to perform the repairs. He said that no estimates were provided and no approvals were sought. He added that when he asked the shop to estimate when they would be finished with the annual, they declined to commit to any date and told him that “it will be done when it’s done.” (The aircraft spent nearly two months in the shop for the 2009 annual.)

I asked the owner whether any of the repairs had been done at his request, and whether he had submitted a squawk list to the shop when the annual started. He said no, the airplane had been squawk-free.

When I pored over the five-page single-spaced description of the work that had been done, I found that it was completely over the top. I won’t bore you with the details—it wouldn’t fit in this article—but as my A&P/IA mentor Phil Kirkham is wont to say, “we were just looking for an annual inspection, not a showplane restoration!”

How It Should Be Done

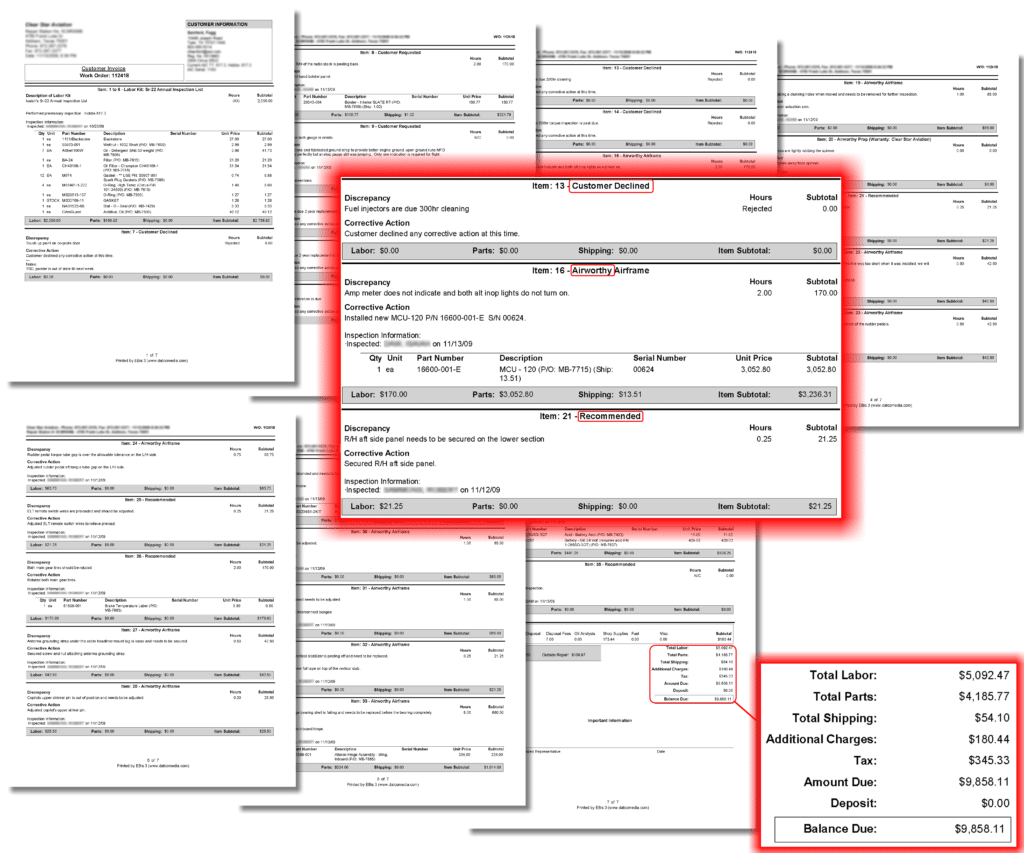

I emailed the Bonanza owner a copy of a recent annual inspection invoice that we’d received for one of our managed-maintenance clients so he could see what a proper invoice looked like:

I pointed out that this invoice itemizes each individual maintenance task, starting with the inspection followed by the repairs, and shows the labor charges, parts cost, and outside work (if any) for each task. I pointed out that each individual task was clearly labeled as to whether it was an airworthiness item or a recommended one, and for the recommended items whether the client had approved or declined the item. This is the level of detail that needs to be included on any maintenance invoice. I explained that we managed this SR22 annual (as we do all of our annuals) on a step-by-step basis.

First, we ask the shop to tell us its flat-rate inspection fee for the aircraft, and exactly what is included in that flat rate. We review this with our client and obtain his concurrence, then approve the shop to perform the inspection for the quoted flat-rate fee, with clear instructions that they are authorized to perform only the inspection, and not to perform any repairs or order any parts (yet).

Once the inspection is complete, the shop presents us with a work order that contains a discrepancy list, repair recommendations, and detailed estimates (parts/labor/outside work) for each recommended repair. (This discrepancy list and estimate looks very much like the invoice, and is generated by the same software.) We review the discrepancy list with the client and make recommendations as to which items should be approved and which should be declined. Once we and our client are in agreement, we give written direction to the shop that approves certain of the repairs and declines others.

The shop updates its work order to show which items have been approved and which have been declined, then proceeds with the approved work. At the completion of the work, the shop presents us with an invoice that should be very nearly identical to the approved items on the estimate, so there should be no surprises. We review the invoice, compare it to the estimate, and if we don’t see anything questionable, we advise our client that the invoice is approved for payment. The client then pays the bill and picks up the airplane from the shop.

This structured protocol ensures that the owner remains in control of his maintenance, is “in the loop” on all major decisions, and does not suffer from “sticker shock” when he receives the invoice. It’s the way maintenance should be done.

I advised the Bonanza owner to handle his future annuals and major maintenance events is a similar step-by-step fashion, and to insist on receiving detailed written discrepancy lists, repair estimates and invoices that clearly itemize the cost of each individual repair. I suggested that if his current shop was unwilling to work in such a structured fashion and provide such documentation (and I’m almost certain that they will refuse to do so), he would be well advised to find another shop that is willing to work in a more professional fashion.

You bought a plane to fly it, not stress over maintenance.

At Savvy Aviation, we believe you shouldn’t have to navigate the complexities of aircraft maintenance alone. And you definitely shouldn’t be surprised when your shop’s invoice arrives.

Savvy Aviation isn’t a maintenance shop – we empower you with the knowledge and expert consultation you need to be in control of your own maintenance events – so your shop takes directives (not gives them). Whatever your maintenance needs, Savvy has a perfect plan for you: