Why don’t more A&Ps use engine monitor data for troubleshooting?

The owner of a 2005 Cessna T182 was on vacation in Key West Florida. He decided to go up for a local sightseeing flight, but when he started the Lycoming TIO-540 engine it seemed to be running unusually rough. When he looked at the engine page on his G1000, the EGT and CHT on the #3 cylinder seemed unusually low at first. After a few minutes, however, the EGT and CHT normalized and the roughness cleared up. He taxied out, did a thorough pre-flight run-up, and took off. The flight was uneventful.

The next morning as the owner and his family were about to depart Key West for home, the roughness reappeared but this time didn’t go away as the engine warmed up. Leaning seemed to help some, but did not resolve the problem completely. Once again, cylinder #3 appeared to be cold on the G1000.

Why Cold?

After unloading his family, the Skylane owner took the aircraft to a mechanic on the field, who ran the engine and confirmed that the engine was running rough. The mechanic told the owner he thought that the RSA fuel servo was at fault. The A&P discussed the problem with another technician who agreed with his diagnosis.

The mechanic proposed to remove the RSA fuel servo and overnight it out to Precision Airmotive for bench testing and repair. This would leave the aircraft grounded and the owner stranded in Key West for a week. The estimated cost for an overhauled fuel servo was about $2,600.

Before authorizing this work, the Skylane owner wisely decided to seek a third opinion. His request was fielded by my partner in crime Paul New A&P/IA, who owns Tennessee Aircraft Services and is a world-class Cessna expert and superb diagnostician. Paul had the owner describe the symptoms in detail, and quickly concluded that this sure sounded like a classic case of Lycoming “morning sickness” caused by a sticky exhaust valve. Paul explained to the owner that the reported symptoms could not possibly be caused by a faulty RSA fuel servo, since there is no way that a fuel servo problem could affect just one cylinder. However, a clogged #3 fuel nozzle could also cause the cylinder to be cold and the engine to run rough.

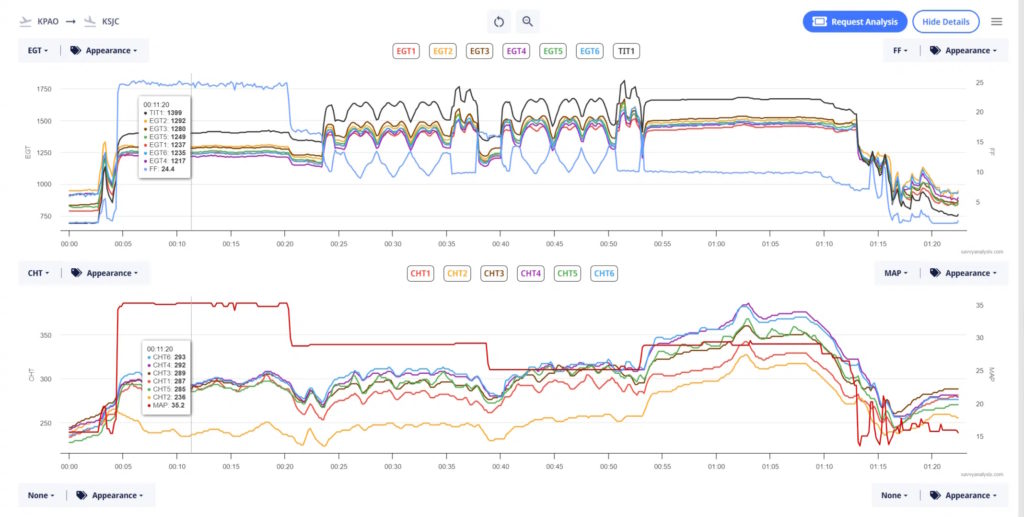

Just to be absolutely sure, Paul asked to see the engine monitor data from the Skylane’s G1000. The owner sheepishly admitted that he’d neglected to install an SD card in the bottom slot of the G1000, so no data had been logged. Paul convinced the owner to obtain an SD card, insert it into the bottom slot, and do another ground run so that the data could be captured and uploaded to the Savvy platform.

When Paul reviewed the engine data, it was clear that the data was not consistent with a clogged injector or any other fuel system problem. Cylinder #3 was producing meaningful EGT (so it was getting fuel and spark), but was not producing meaningful CHT (so it wasn’t producing power). Those findings were consistent with an exhaust valve that was not fully closing.

At Paul’s suggestion, the local mechanic removed the spark plugs from cylinder #3 and predictably found them to be oil fouled. After cleaning the plugs, the engine ran a bit better, and smoothed out after several more ground runs. This reinforced Paul’s diagnosis of a sticky #3 exhaust valve, since a sticky valve is invariably worst when the cylinder head is cold and typically frees up as it heats up—hence the colloquial term “morning sickness.”.

After digesting all this information, the Skylane owner decided to fly his family home—which he did without incident—and have his regular mechanic ream the #3 exhaust valve guide. Paul referred the owner to Lycoming Service Bulletin 388C which describes the procedure for doing this without cylinder removal. The owner subsequently reported that reaming the guide appeared to have resolved the issue completely.

Why Hot?

Half a world away, another owner in Tzfat, Israel, was in a panic. He and his partner had just spent nearly $50,000 to replace the IO-550-N engine in their 2003 Cirrus SR22 with a Continental factory-rebuilt engine.

On the first few flights after the engine change, the CHTs were predictably higher than what the owners were accustomed to seeing—especially cylinders #2 and #6—but they understood that higher-than-normal CHTs are normal during the initial break-in period. Continental recommends that CHTs be kept at or below 420ºF during break-in, although we seldom see them exceed 400ºF in an aircraft like the Cirrus SR22 with its exceptionally efficient cooling system.

By the time the new engine had four hours in service, most of the CHTs (including #2) seemed to be coming down nicely, but #6 wasn’t and actually seemed to be getting worse. Then on a takeoff from a small airport 100 miles away from home base, CHT #6 rose smoothly to 470ºF, while the other five CHTs stabilized in the 360ºF to 380ºF range. The pilot immediately reduced power and returned to the airport. By the time the airplane touched down, CHT #6 had come back down to about the same as the other cylinders.

The pilot attempted another takeoff, but CHT #6 started to run away again, so he aborted the takeoff roll and stopped on the remaining runway. According to the pilot, the #6 EGT remained normal throughout, about in line with the EGTs for the other five cylinders. Only the #6 CHT went crazy.

Based on the pilot’s verbal report, we suspected that the high CHT #6 was some sort of indication problem, because a “real” combustion anomaly would have been confirmed by an anomalous EGT. But experience has made us skeptical of eyewitness accounts, so I told the owner I’d feel a lot more comfortable giving him advice if I could see the actual engine data. The owner arranged to dump the data from his Avidyne Entegra MFD and upload it to the Savvy platform, where I and two of my colleagues reviewed it.

Our review of the data immediately confirmed our suspicions that the #6 CHT indication was bogus. At one point, its value changed more than 40ºF between two adjacent data samples taken six seconds apart. A 40ºF change in CHT in six seconds is simply not possible—it defies the laws of physics. I’ve studied data from literally thousands of flights—we now have roughly 7,000,000 GA flights in our database—and the most rapid CHT rise I’ve ever seen—during a destructive pre-ignition event that melted the piston—was about 1.5ºF per second. This one changed 7ºF per second, and that’s simply not plausible. Obviously the CHT #6 indication was lying, due either to a faulty probe or a bad connection.

We asked whether it was possible to have the #6 and #4 CHT probes swapped to verify our diagnosis. Unfortunately, there were no services at this airport, and no mechanic available to swap the probes. Based on our review of the data, we were sufficiently confident in our diagnosis that we recommended that the owner fly the airplane home and have the CHT indication problem debugged there. The flight was uneventful, the CHT probe was replaced, and the new engine was doing just fine.

Hot Hot Hot

Another client flew his Cessna T210 to a top-notch California shop for its annual inspection. The shop repaired a number of discrepancies, and sent out both magnetos for their 500-hour IRAN. Two weeks later, the owner came to pick up his aircraft. He paid the shop’s invoice, fired up, taxied out, performed a normal engine runup, and took off.

About 90 seconds after takeoff, the airplane’s JPI EDM-700 engine monitor alarmed, and the pilot saw that CHT #2 had passed 395ºF and was still rising. He immediately reduced power and told the tower that he was returning to land. He taxied back to the shop and described the problem to the DOM.

Because both magnetos had been removed and reinstalled, the DOM’s first thought was that the magneto timing was adjusted too far advanced. He had his lead IA re-check the mag timing (while he watched) using the shop’s fancy Pro-3600 digital inclinometer, and it was spot-on within 0.2º of spec. The IA checked the #2 fuel nozzle and found it clean and unobstructed. He also checked the #2 cylinder’s spark plugs and they looked fine.

More than an hour later, the owner attempted a second takeoff and this time the CHTs were even worse. CHT for cylinders #1, #2 and #3 reached 400ºF, 408ºF and 411ºF, respectively, before the pilot reduced power and came back to land. He dumped his JPI data on a USB thumb drive, uploaded it to the Savvy platform, and phoned me. I pulled up the data on my computer while he was still on the phone.

I compared the engine data for the last pre-annual flight to the data for the two aborted post-annual flights. I found that during takeoff and initial climb, both post-annual flights had CHTs about 50ºF higher and EGTs about 50ºF lower than the pre-annual benchmark flight. This could mean only one thing: advanced magneto timing. I told the owner that I understood the shop had just checked the mag timing and found it spot-on, but I also knew that the engine data wasn’t lying, so I urged the owner to have the shop check the mag timing yet again. The high-CHT/low-EGT condition I was seeing in the data would require that at least one magneto had timing advanced by 3º to 5º from what it should be.

Two hours later, I spoke with the DOM, who was a good friend. He told me that after the owner informed him of my diagnosis, he personally re-checked the mag timing, but this time instead of using the shop’s fancy $360 digital inclinometer, he used his old-fashioned E-25 mechanical “flower pot” timing protractor that he’d used for more than 30 years before buying the digital unit. Lo and behold, the flower pot revealed that the timing of both mags was advanced 3º beyond the proper timing specification. The shop’s digital inclinometer was off by 3º. It turned out that one of the technicians had accidentally dropped it on the concrete hangar floor, and it was never quite the same after that.

The shop readjusted the mag timing using the old flower-pot method, and the owner flew home with his EGTs and CHTs right where they were supposed to be.

They Keep Coming

Then there was the Beech F33A whose owner reported the engine ran rough at high power, and the engine monitor “flashed on #6.” He took it to his shop, who changed the spar plugs, cleaned the fuel screen and nozzles, and did a compression check. A high-power ground run revealed the problem was unchanged. The shop then pulled the #6 valve springs and determined that the valve guides were not excessively worn, the valves were not sticking, and the lifters were not collapsed.

Out of ideas, the A&P emailed me to see if I had any ideas. “I would hate to pull the cylinder for nothing and find I still have the problem,” he said. “Any help would be greatly appreciated.”

Three guesses what I suggested to the A&P…

When a pilot reports engine issues, the first thing the A&P should do is review the engine monitor data, but very few do. Diagnosis shouldn’t be done by attacking the airplane with tools, it should be done by gathering data.