This is part two of an article about sticky valves. Part one is here.

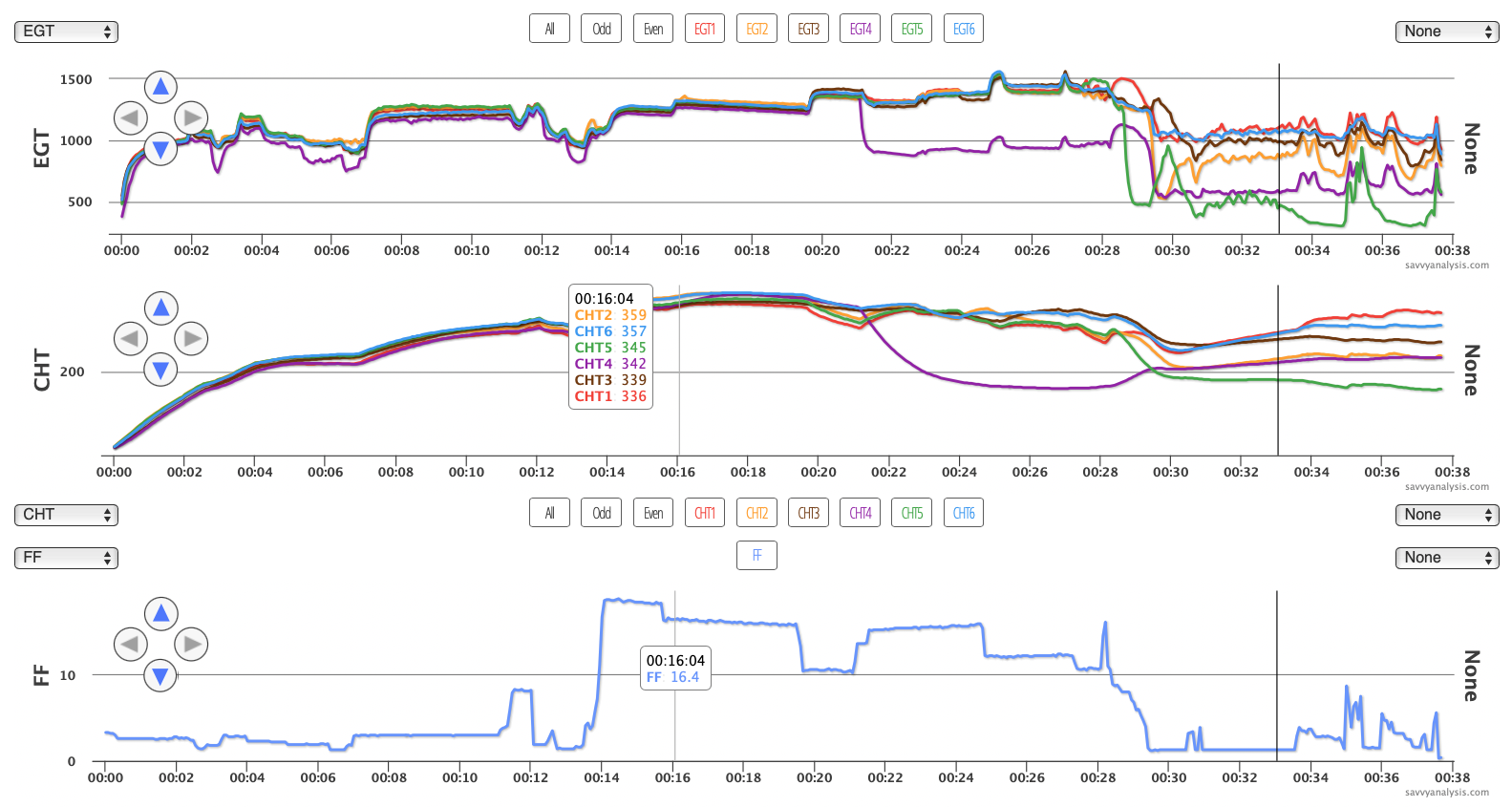

The cliffhanger was a Cessna 182 with a wobbly trace in EGT 4 for the first 14 mins of ground ops. Your homework was to decide if it was a sticky valve or something else. Here’s the whole flight.

One of the questions we get most often is “should I have seen this in the data before the event?” In this case the answer is yeah, there’s something going on with cyl 4 before takeoff, but it settles down at takeoff and the EGT 4 trace just before the event at the 21 min mark looks pretty normal. And then all of a sudden it’s a five cylinder engine. And it gets worse at the 28 min mark when cyl 5 drops out – no hint of trouble from 5 in the earlier data.

Here’s a picture of the push rod tubes for cyl 4 taken after the successful forced landing.

In part one, I built a table for each sticky valve incident. Here’s the table for this one.

| Engine Model | Cyl# | Length of Event (mins) | Drop in CHT? | Drop in TIT? | RPM fluctuation? | Oil Temp | OAT | First Flight That Day? | Recurrence in Subsequent Flights? |

|---|---|---|---|---|---|---|---|---|---|

| IO-540-AB1A5 | 4 | 17 | Y | n/a | N | 159 – 162 | 73 | Y | N |

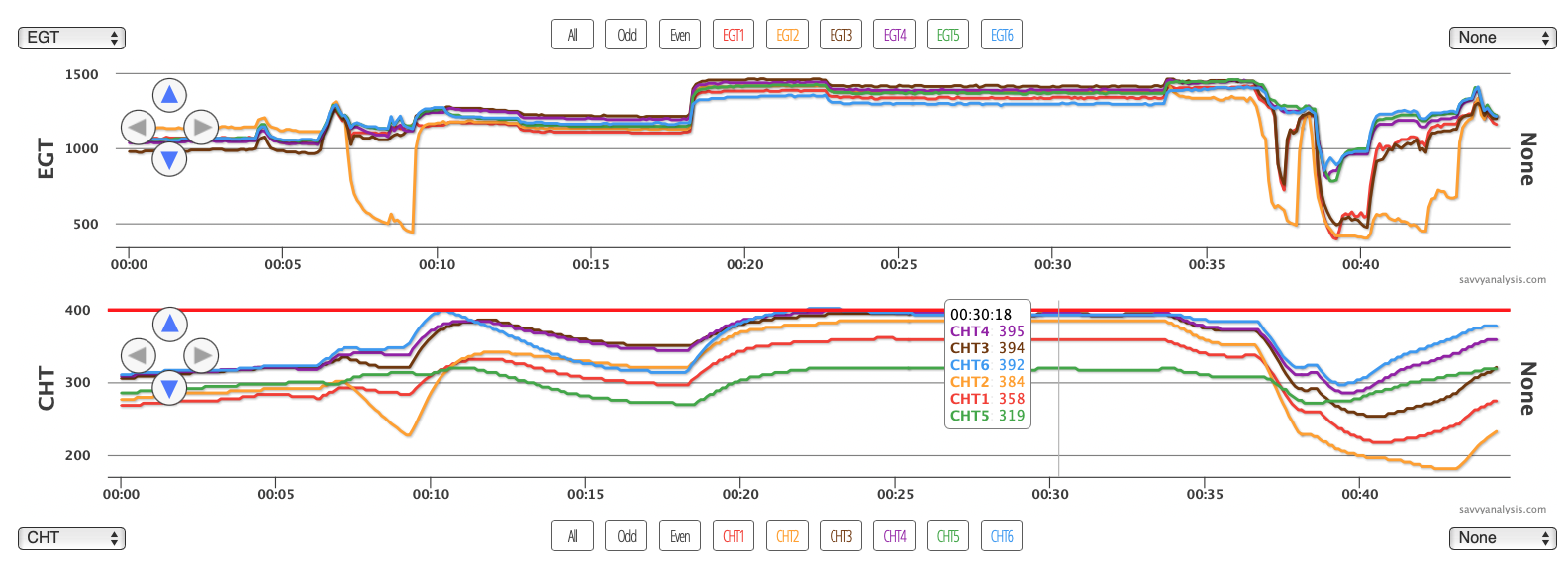

Next is data from a Piper PA-24 Comanche with a Lycoming O-540-A1A5 engine. This is EGT and CHT only – RPMs not logged. There’s nothing special about the cursor position, just getting it out of the way of the event. Sticky valve or something else?

It’s a sticky valve. Oil temp is not displayed but shows a flatline of 180º from engine start to the event at the 7 min mark. Notice the EGT 2 had been a little high until the runup. Notice also that EGT 2 is a little low at the 33 min mark before it drops about 4 mins later. Data in the table for this one is for the first event, which ends when power is applied for takeoff.

| Engine Model | Cyl# | Length of Event (mins) | Drop in CHT? | Drop in TIT? | RPM fluctuation? | Oil Temp | OAT | First Flight That Day? | Recurrence in Subsequent Flights? |

|---|---|---|---|---|---|---|---|---|---|

| IO-540-A1A5 | 2 | 3 | Y | n/a | n/a | 180 | n/a | N | Y |

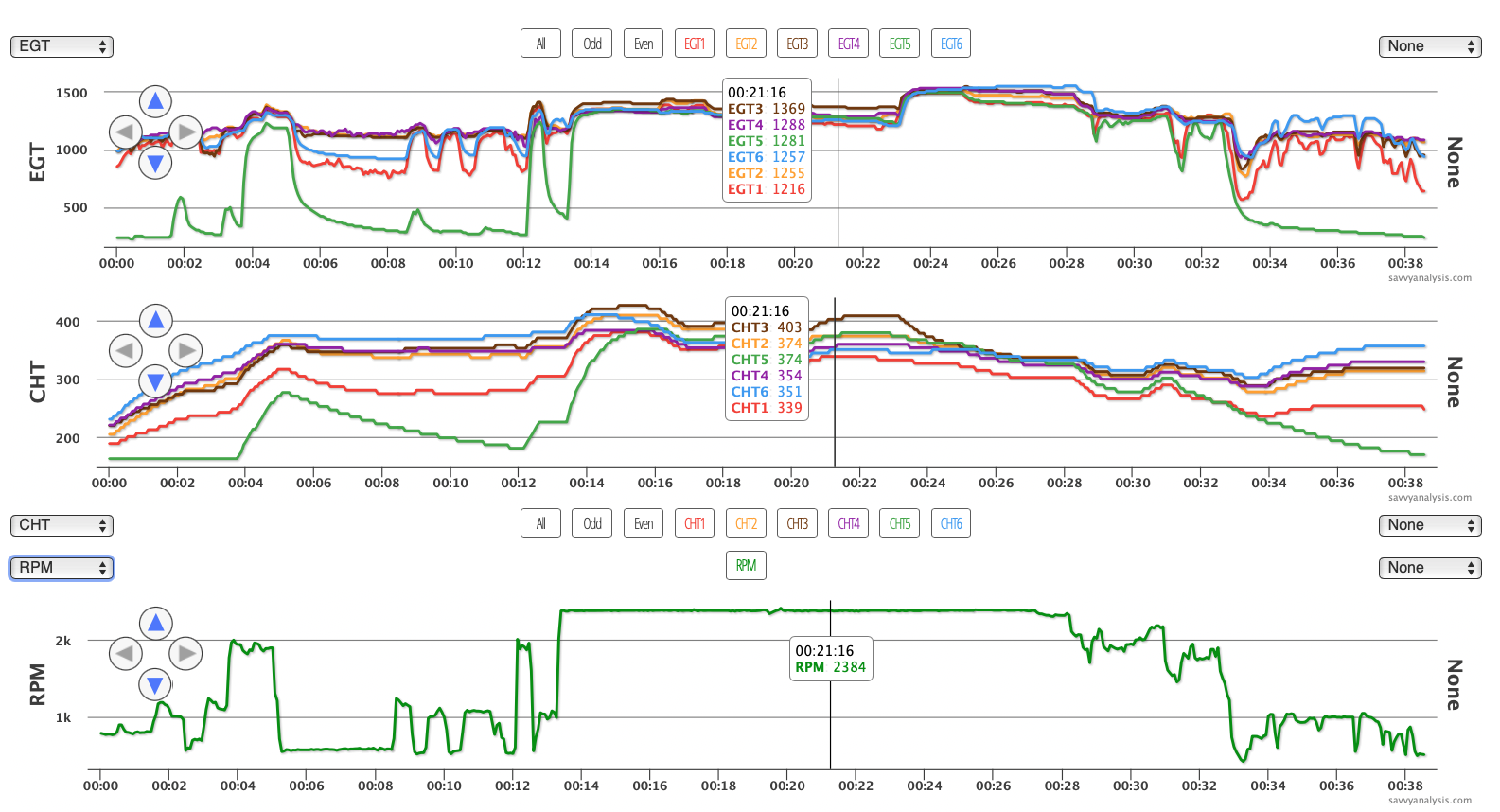

Next is data from another Piper PA-24 Comanche with a Lycoming O-540-A1A5 engine. Is cyl 2 a sticky valve or something else?

Because CHT2 doesn’t corroborate the dramatic moves of EGT 2, we think this is bad data. Supporting evidence is the flatline at engine start and the instantaneous recovery – also seen at the 39 min mark. Sometimes we’ll see a loose connection act up on the ground then be normal in the air – like this one. And sometimes it’s the other way around. I’ll skip the data table on this one since it’s not a sticky valve.

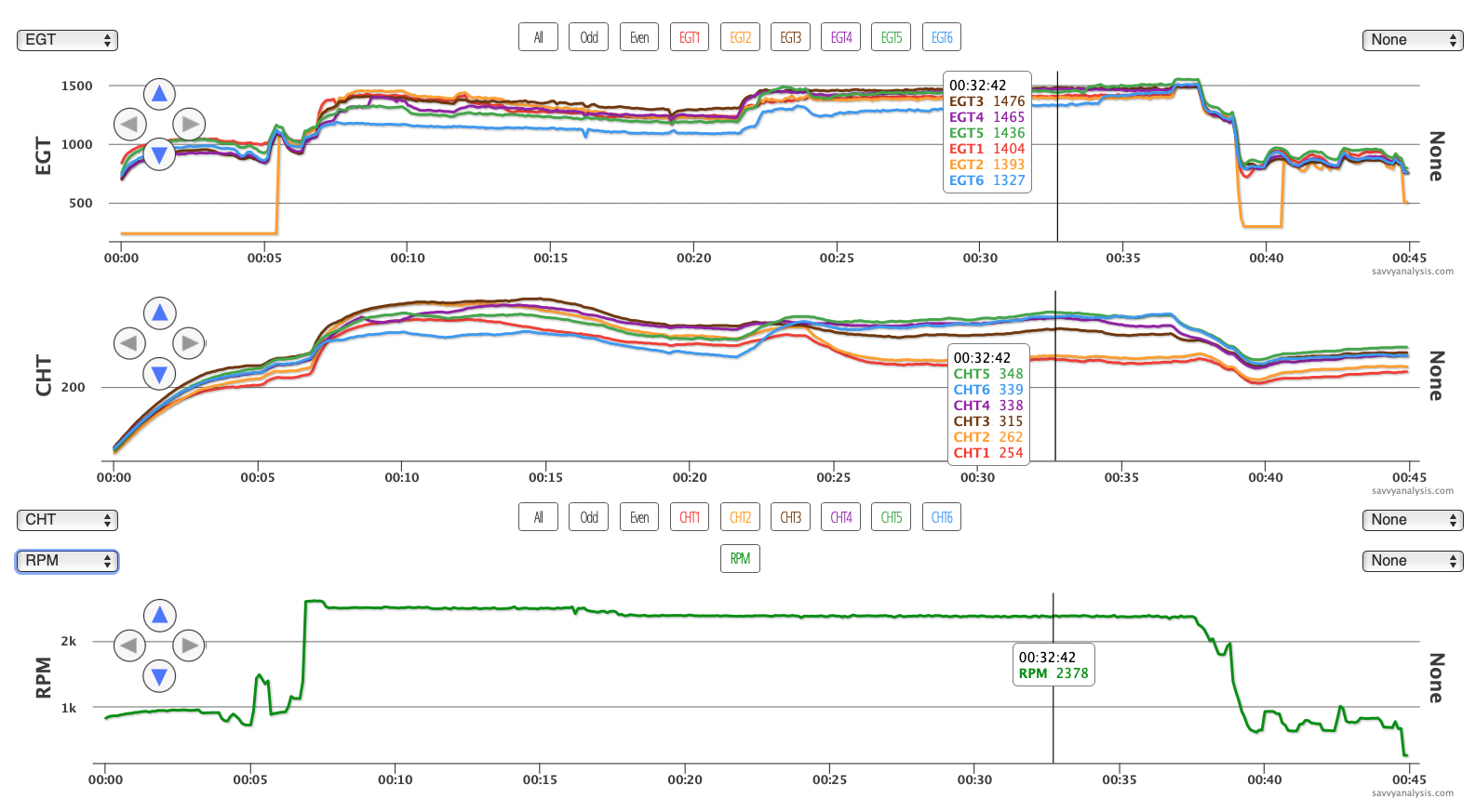

Next is data from a Piper PA-28-236 Dakota with a Lycoming O-540-J3A5D engine. Is cyl 5 a sticky valve or something else?

This one looks like a sticky valve, and it looks like it unsticks when RPMs are in the 1500 or higher range. Here’s a subsequent flight where the stickiness takes a while to develop – in contrast to the flight above.

Data in the table is for the first of the two.

| Engine Model | Cyl# | Length of Event (mins) | Drop in CHT? | Drop in TIT? | RPM fluctuation? | Oil Temp | OAT | First Flight That Day? | Recurrence in Subsequent Flights? |

|---|---|---|---|---|---|---|---|---|---|

| IO-540-J3A5D | 5 | 10 | Y | n/a | N | 180 | 76 | N | Y |

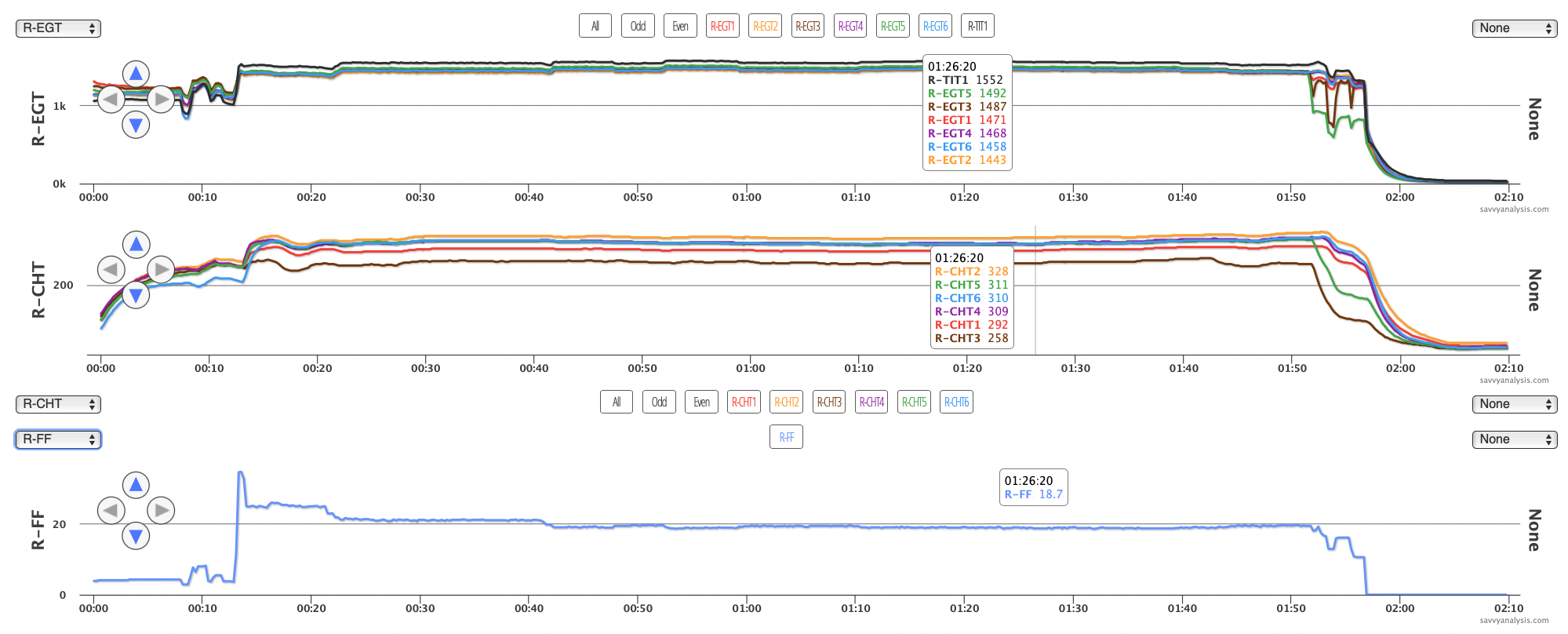

Here’s data from the right engine of a Cessna 414 with a Continental TSIO-520 engine and data from a JPI 760 with a 2 sec sample rate. This is the whole flight with R EGT, R CHT and R FF.

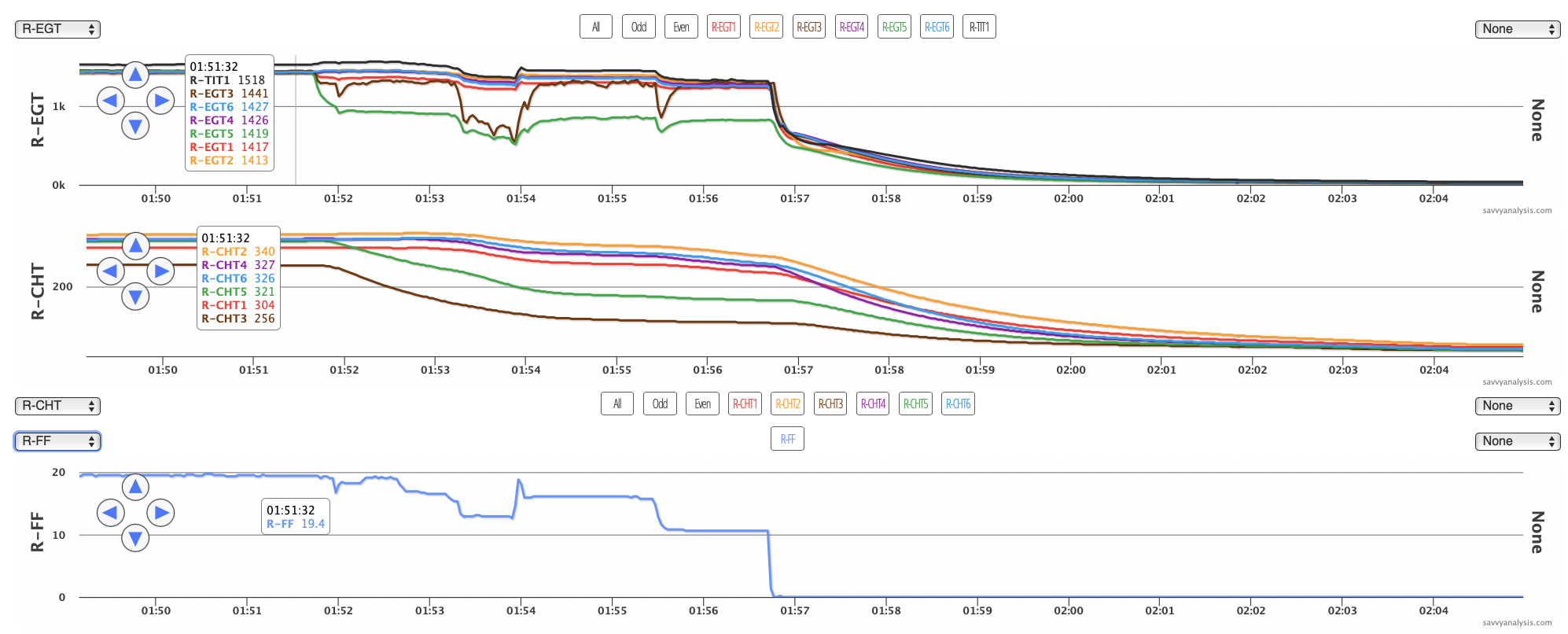

Here’s the same flight zoomed in to the exciting part. Cylinders 3 and 5 stop making power just to the right of the cursor. Sticky valve or something else?

Technically, yes. Inspection revealed a broken rocker arm on the intake valve of cyl 5. Intake, not exhaust. So when the spring held the intake valve closed, combustion took a hit. And the adjacent cylinder #3 took a hit, too.

If you were wondering if the data would look different for a sticky intake valve versus a sticky exhaust valve, this example suggests no. The sensors don’t appear to care who stopped combustion, they just know it isn’t happening anymore.

It would be nice if we could draw some conclusions from these examples. Here’s a compilation of the individual tables shown earlier. See if you can find a pattern.

| Engine Model | Cyl # | Length of Event (mins) | Drop in CHT? | Drop in TIT? | RPM fluctuation? | Oil Temp | OAT | First Flight That Day? | Recurrence in Subsequent Flights? |

|---|---|---|---|---|---|---|---|---|---|

| O-540-L3C5D | 1 | 7 | Y | Y | Y | 86 – 131 | 86 | Y | Y |

| O-540-L3C5D | 6 | 8 | Y | Y | N – smooth from 7 to 8 mins | 86 – 131 | 86 | Y | Y |

| subsequent flight | |||||||||

| O-540-L3C5D | 1 | 4 | Y | Y | Y – follows EGT 1 | 76 – 125 | 62 | Y | Y |

| O-540-L3C5D | 6 | 4 | Y | Y | N | 76 – 125 | 62 | Y | Y |

| TIO-540-AH1A | 1 | 6 | Y | N | Y | 124 – 162 | 73 | Y | N |

| IO-540-AB1A5 | 4 | 17 | Y | n/a | N | 159 – 162 | 73 | Y | N |

| IO-540-A1A5 | 2 | 3 | Y | n/a | n/a | 180 | n/a | N | Y |

| IO-540-J3A5D | 5 | 10 | Y | n/a | N | 180 | 76 | N | Y |

Here’s what I notice. These are all 540s. Not picking on them but I didn’t have good examples from the Lycoming 360 series. If you have them, post a comment including your flight url and maybe we’ll take another look at sticky valves from smaller engines after a while. Also didn’t have good examples from Continental, but Mike gave a good explanation for that in last year’s AOPA article.

The only thing you can pretty much take to the bank is the drop in CHT, which happened every time. Oil temp before and after the event moved on most of these, but not all, and not enough that if you saw an oil temp rise you could go “aha!.” I don’t think we’re ready to drive a stake through the heart of the “morning sickness” OWT, but I think it’s safe to say valves stick even when it’s not morning. For these samples, all but one of them are on an end. 4 is a middle cylinder. We’d need a lot more data to see if that’s significant.

There’s one more symptom that sticky valves have according to Lycoming’s research. Carbon build-up on the valve stem can keep the valve from turning. If you suspect a sticky valve, check the rocker wear pattern on the valve tip. That’s a good indicator for whether the valve is turning in service or not.

We developed an algorithm for detecting burned valves – FEVA – and began the process of developing an algorithm for detecting stuck valves – SEVA – with the goal of detecting incipient stickiness and preventing engine damage. As you can see, it’s hard enough just to identify a sticky valve indicent, much less to see it coming. But we’re not giving up.