It has been a while since we took a look at sticky valves. I’m not going to write about why valves stick and how to keep it from happening, although I have a great resource for that. Earlier this year Mike Busch wrote an article for AOPA Pilot called Why Valves Stick. And here’s a link to his EAA webinar on the same subject. I’m also not going to write about how to fix a sticky valve, although I have a great resource for that too. Here’s Paul New’s article about Lycoming exhaust valves with references to Lycoming’s Service Bulletins and Instructions. This Puzzler is about what it looks like on your engine monitor when a valve sticks, so you can spot it in real time as it happens, or spot it as you review your data after a flight. Our eventual goal is to see if there’s some clue in the data leading up to these events that could prevent them from occurring. We’re not there yet but it’s a good project for machine learning.

In the sprit of good puzzling, there are some verified examples of sticky valves, but not all of the examples are sticky valves.

Ground rules –

- Most sticky valve scenarios happen after engine start and end by takeoff. So for those I have zoomed into the early part of the flight data so we get a better look at what we’re interested in – and you can assume there was no recurrence later in the flight.

- Many of these resulted in bent pushrods so they were easily verified.

- All of the sticky valve examples I chose are exhaust valves, although we did have a case of an intake valve sticking earlier this year in a Mooney powered by a Lycoming IO-360.

- All of these are from Lycoming engines. That’s not to say it can’t or won’t happen with a Continental or other manufacturer – just saying that I gathered these from typical analysis requests over a year or more and so far have seen only Lycomings. Mike’s article offers a good theory as to why that is.

- My typical preferred display is EGTs, CHTs and FF. For these it’s EGT, CHT and RPMs. because RPM is usually a better indicator of engine roughness than FF at these low power settings.

Before we look at the data, what would you expect to see if an exhaust valve stuck closed? In the suck-squeeze-bang-blow cycle, blow isn’t happening. If exhaust gas stops filling the exhaust riser where the EGT sensor is, EGT should drop. Suck is compromised because there’s nowhere to put the new batch of fresh induction air. Squeeze still works when both valves are closed, and bang is compromised as a result of suck, which should result in lower CHT. Would the EGT of adjacent cylinders rise or fall because the induction system is contaminated? Would TIT – if we have it – corroborate the combustion anomaly? Would RPMs corroborate the combustion anomaly? Would that only happen with fixed-pitch props? Do sticky valves – aka morning sickness – happen more if it’s the first flight of the day? Or if OAT is lower than some number? All good questions – let’s take a look.

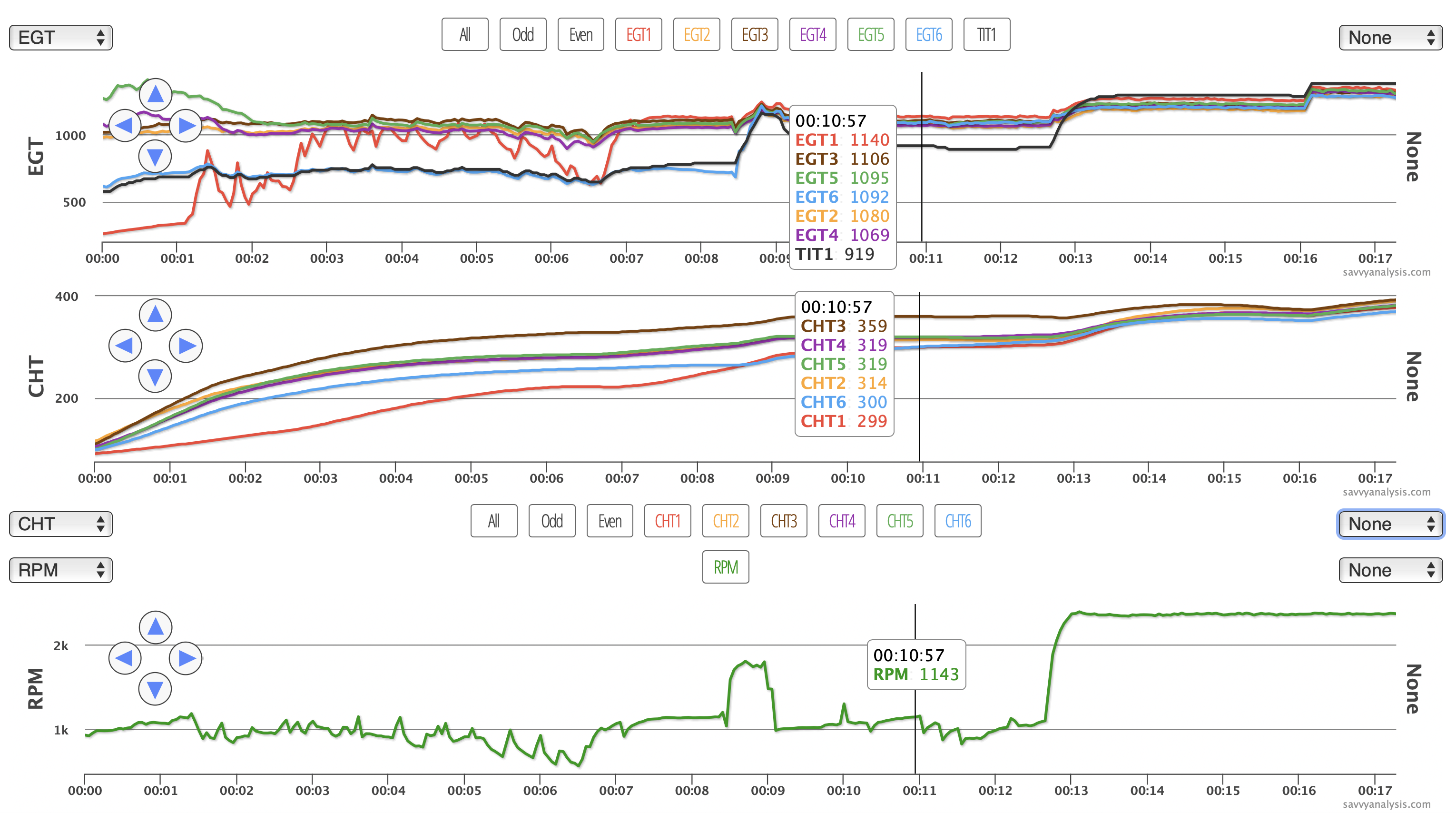

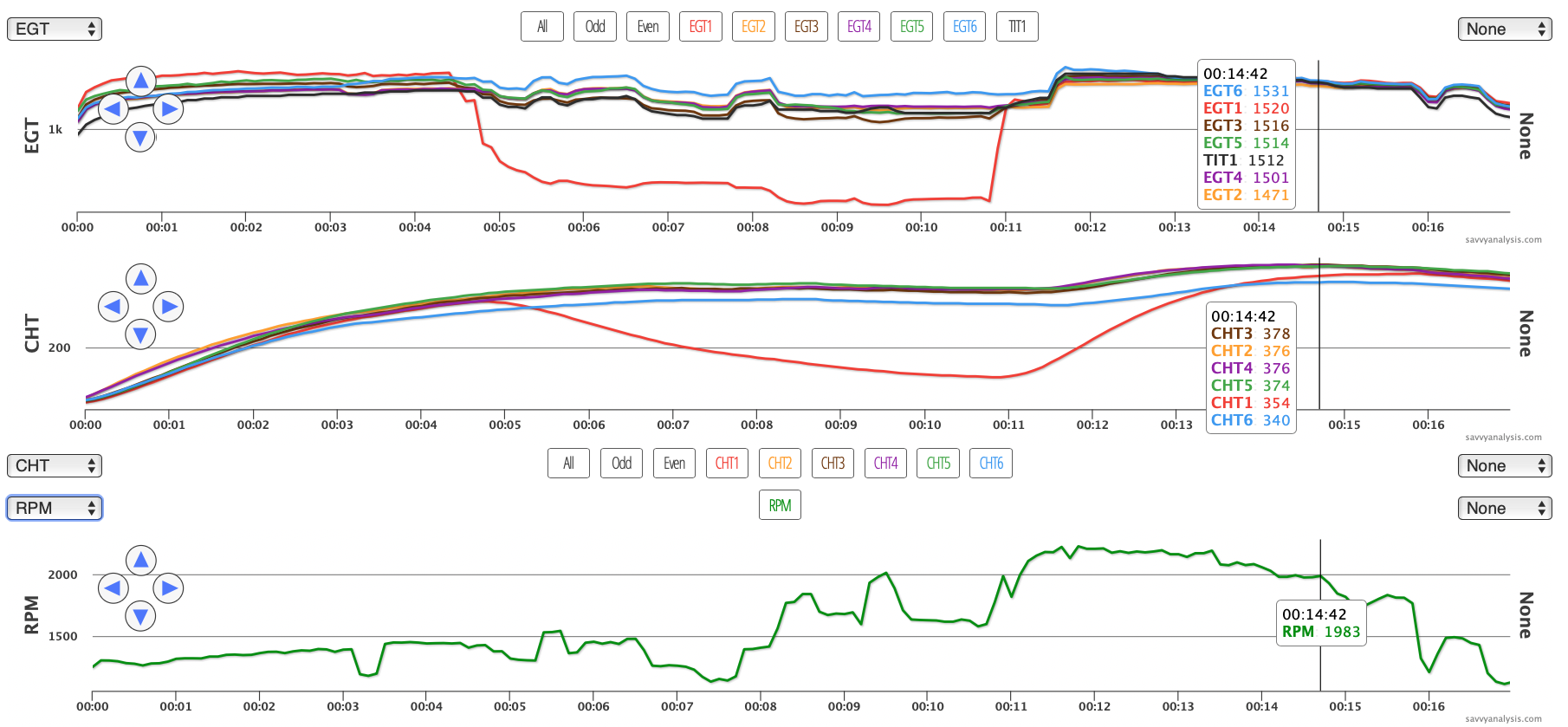

Let’s get started with data from a Cessna TR812 Turbo Skylane RG powered by a Lycoming O-540-L3C5D. Not a typo – it’s a carbureted turbo-normalized engine, with a constant speed prop. Data is from a JPI 830 with a 2 sec sample rate. Sticky valve or something else?

If you guessed sticky valve you’re one for one. Actually, two for one. Upon examination of the engine, valves in cyls 1 and 6 were found to be sticking. Cyl 6 – the blue trace – starts out at about 600º and stays in that range for 8 mins, then joins the others for the runup. Cyl 1 starts much lower, but is much more kinetic than 6 and recovers at the 7 min mark. EGTs 5 and 4 were high initially but stabilize by the 2 min mark.

Here’s data from a flight a few days later with very similar patterns.

I thought the best way to track these characteristics would be a table, so here’s the table for the two flights from this engine, and at the end of the article I’ll include a table with all of the sticky valve examples.

| Engine Model | Cyl # | Length of Event (mins) | Drop in CHT? | Drop in TIT? | RPM fluctuation? | Oil Temp | OAT | First Flight That Day? | Recurrence in Subsequent Flights? |

|---|---|---|---|---|---|---|---|---|---|

| O-540-L3C5D | 1 | 7 | Y | Y | Y | 86 – 131 | 86 | Y | Y |

| O-540-L3C5D | 6 | 8 | Y | Y | N – smooth from 7 to 8 mins | 86 – 131 | 86 | Y | Y |

| subsequent flight | |||||||||

| O-540-L3C5D | 1 | 4 | Y | Y | Y – follows EGT 1 | 76 – 125 | 62 | Y | Y |

| O-540-L3C5D | 6 | 4 | Y | Y | N | 76 – 125 | 62 | Y | Y |

Next up is data from a Turbo Saratoga with a Lycoming TIO-540-AH1A engine with a constant speed prop. Data is from a JPI 730 with a 6 sec sample rate. RPMs aren’t logged so I included FF instead. Sticky valve or something else?

If you guessed no sticky valve you’re right again. It’s an injector clog causing high EGT and CHT for cyl 6 at max FF, but when FF drops below about 20 GPH it’s ok again. Those small downspikes in EGT 4 and 2 line up with changes in FF, and are probably related to the dynamic fuel pressure caused by the clog. No table for this one because it’s not a sticky valve.

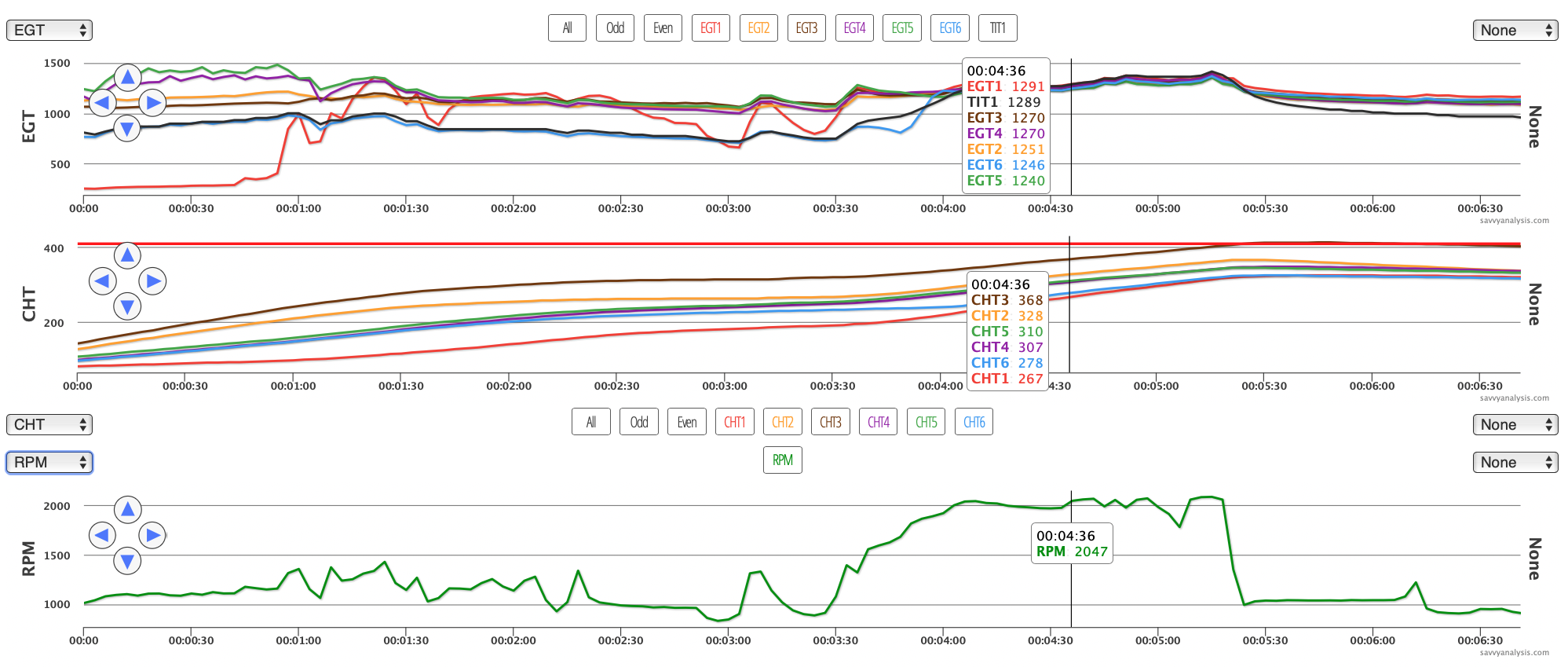

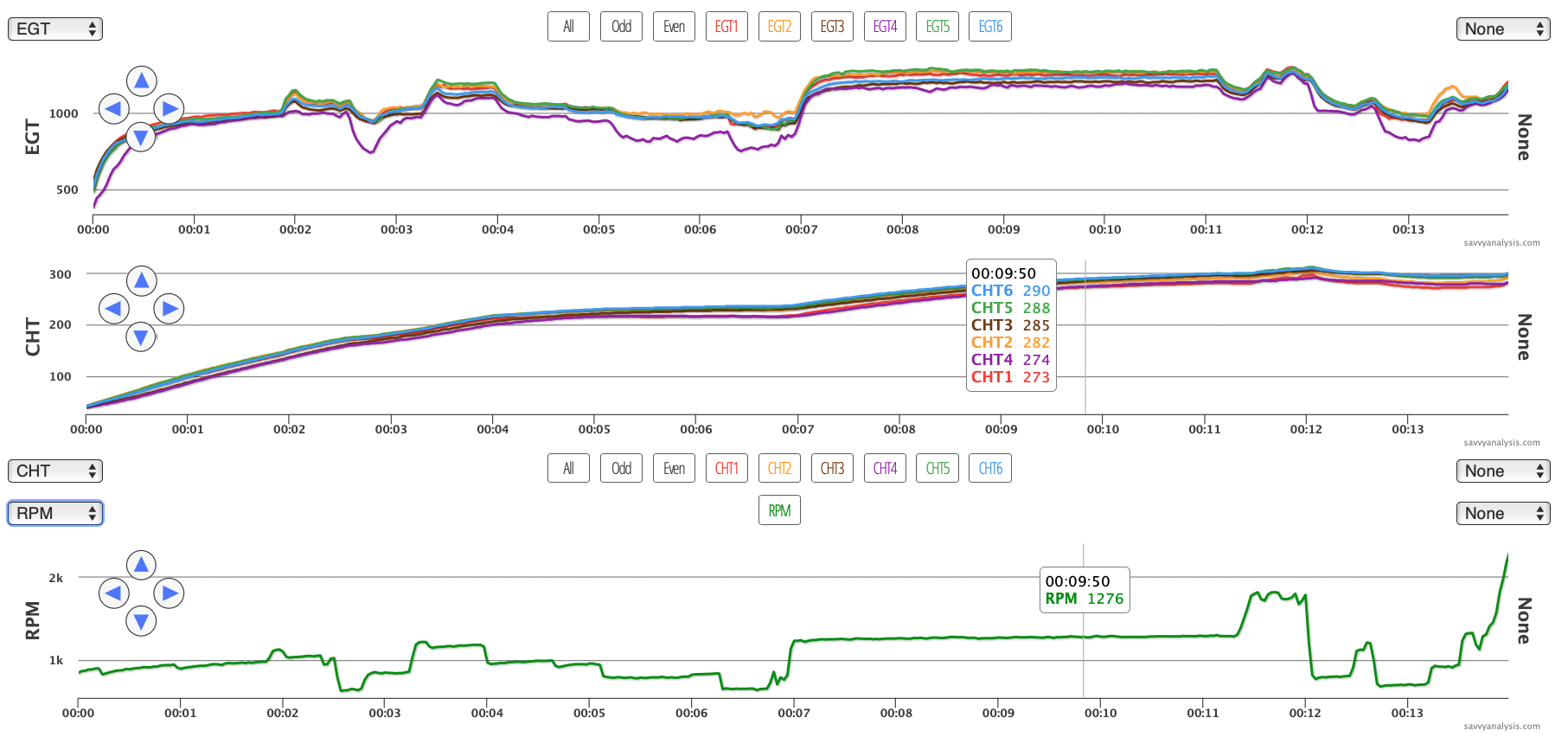

Next is data from a Piper Malibu 350 with a Lycoming TIO-540-AE2A engine and a constant speed prop. Data is from a JPI 930 with a 6 sec sample rate. Sticky valve or something else?

It’s a sticky valve. Unlike the first example, EGT and CHT 1 start out normal – although both are a little high – then there’s an event from 4 to 11 mins. This is all ground ops. Takeoff isn’t until the 23 min mark. RPMs do seem more wobbly after the 4 min mark but still tracking with EGTs. TIT doesn’t really react when cyl 1 drops off. Here’s the table for this one.

| Engine Model | Cyl# | Length of Event (mins) | Drop in CHT? | Drop in TIT? | RPM fluctuation? | Oil Temp | OAT | First Flight That Day? | Recurrence in Subsequent Flights? |

|---|---|---|---|---|---|---|---|---|---|

| TIO-540-AH1A | 1 | 6 | Y | N | Y | 124 – 162 | 73 | Y | N |

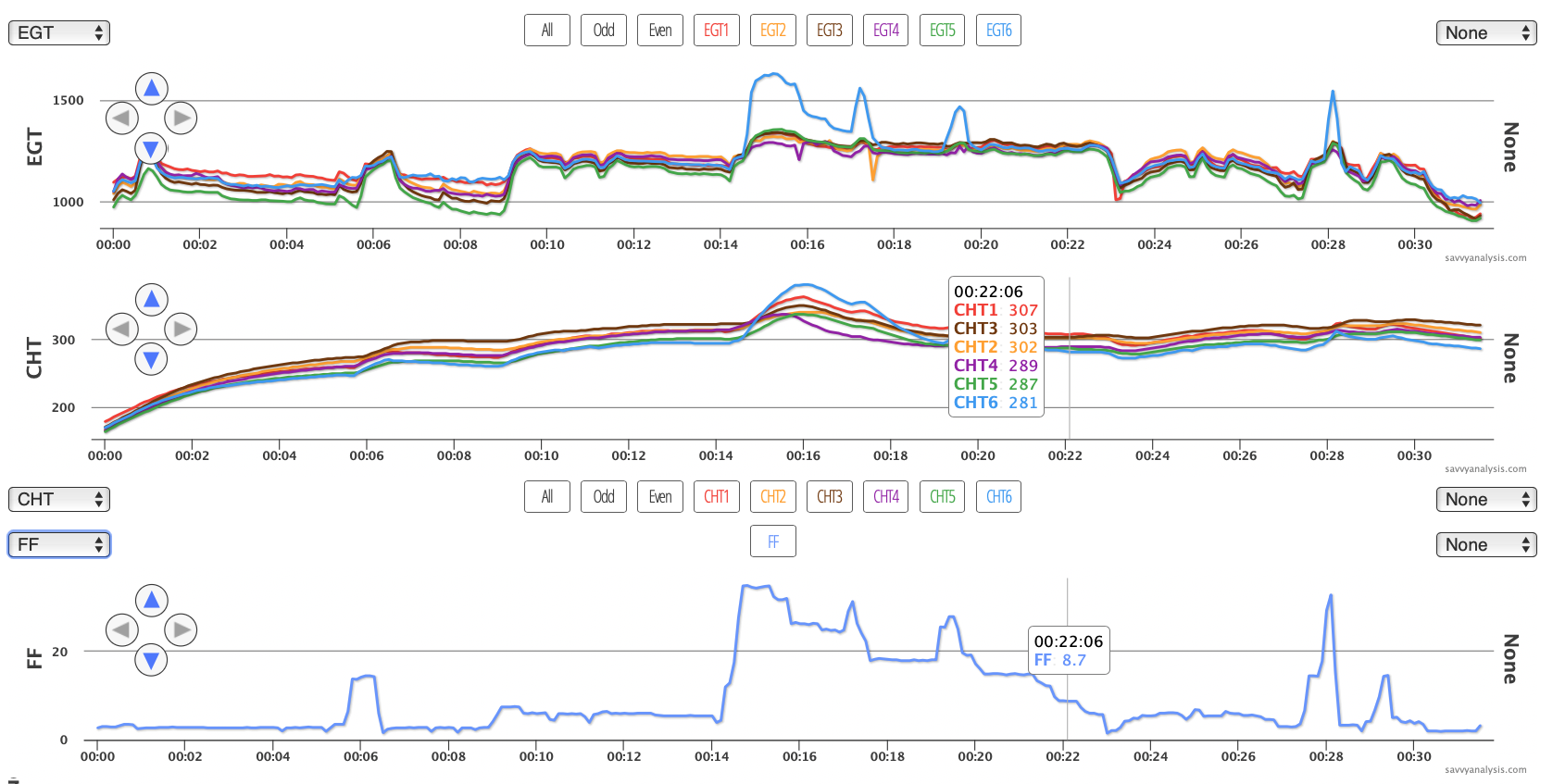

Here’s data from a 2002 (restart) Cessna 182 with a Lycoming IO-540-AB1A5 engine with a constant speed prop. Data is from a JPI 900 with a 2 sec sample rate. Sticky valve or something else?

The question is cyl 4. EGT is slightly low and CHT is lowest, but not by much. Not like the others we’ve seen so far. The good news is you have a month to think about it.

I have five more examples to share before drawing conclusions, and I’m already at my word target for this month. So we’ll finish up this 182 and continue this deep dive into the world of sticky valves in the January Puzzler.

Have a great holiday season and stay safe and healthy.